Regulatory Text

2509.03_Recordkeeping_and_Reporting.docx

NESHAP for Brick and Structural Clay Products Manufacturing (40 CFR part 63, subpart JJJJJ) (Renewal)

Regulatory Text

OMB: 2030-0047

§ 63.7 Performance testing requirements.

(a) Applicability and performance test dates.

(1) The applicability of this section is set out in § 63.1(a)(4).

(2) Except as provided in paragraph (a)(4) of this section, if required to do performance testing by a relevant standard, and unless a waiver of performance testing is obtained under this section or the conditions of paragraph (c)(3)(ii)(B) of this section apply, the owner or operator of the affected source must perform such tests within 180 days of the compliance date for such source.

(i)-(viii) [Reserved]

(ix) Except as provided in paragraph (a)(4) of this section, when an emission standard promulgated under this part is more stringent than the standard proposed (see § 63.6(b)(3)), the owner or operator of a new or reconstructed source subject to that standard for which construction or reconstruction is commenced between the proposal and promulgation dates of the standard shall comply with performance testing requirements within 180 days after the standard's effective date, or within 180 days after startup of the source, whichever is later. If the promulgated standard is more stringent than the proposed standard, the owner or operator may choose to demonstrate compliance with either the proposed or the promulgated standard. If the owner or operator chooses to comply with the proposed standard initially, the owner or operator shall conduct a second performance test within 3 years and 180 days after the effective date of the standard, or after startup of the source, whichever is later, to demonstrate compliance with the promulgated standard.

(3) The Administrator may require an owner or operator to conduct performance tests at the affected source at any other time when the action is authorized by section 114 of the Act.

(4) If a force majeure is about to occur, occurs, or has occurred for which the affected owner or operator intends to assert a claim of force majeure:

(i) The owner or operator shall notify the Administrator, in writing as soon as practicable following the date the owner or operator first knew, or through due diligence should have known that the event may cause or caused a delay in testing beyond the regulatory deadline specified in paragraph (a)(2) or (a)(3) of this section, or elsewhere in this part, but the notification must occur before the performance test deadline unless the initial force majeure or a subsequent force majeure event delays the notice, and in such cases, the notification shall occur as soon as practicable.

(ii) The owner or operator shall provide to the Administrator a written description of the force majeure event and a rationale for attributing the delay in testing beyond the regulatory deadline to the force majeure; describe the measures taken or to be taken to minimize the delay; and identify a date by which the owner or operator proposes to conduct the performance test. The performance test shall be conducted as soon as practicable after the force majeure occurs.

(iii) The decision as to whether or not to grant an extension to the performance test deadline is solely within the discretion of the Administrator. The Administrator will notify the owner or operator in writing of approval or disapproval of the request for an extension as soon as practicable.

(iv) Until an extension of the performance test deadline has been approved by the Administrator under paragraphs (a)(4)(i), (a)(4)(ii), and (a)(4)(iii) of this section, the owner or operator of the affected facility remains strictly subject to the requirements of this part.

(b) Notification of performance test.

(1) The owner or operator of an affected source must notify the Administrator in writing of his or her intention to conduct a performance test at least 60 calendar days before the performance test is initially scheduled to begin to allow the Administrator, upon request, to review an approve the site-specific test plan required under paragraph (c) of this section and to have an observer present during the test.

(2) In the event the owner or operator is unable to conduct the performance test on the date specified in the notification requirement specified in paragraph (b)(1) of this section due to unforeseeable circumstances beyond his or her control, the owner or operator must notify the Administrator as soon as practicable and without delay prior to the scheduled performance test date and specify the date when the performance test is rescheduled. This notification of delay in conducting the performance test shall not relieve the owner or operator of legal responsibility for compliance with any other applicable provisions of this part or with any other applicable Federal, State, or local requirement, nor will it prevent the Administrator from implementing or enforcing this part or taking any other action under the Act.

(c) Quality assurance program.

(1) The results of the quality assurance program required in this paragraph will be considered by the Administrator when he/she determines the validity of a performance test.

(2)

(i) Submission of site-specific test plan. Before conducting a required performance test, the owner or operator of an affected source shall develop and, if requested by the Administrator, shall submit a site-specific test plan to the Administrator for approval. The test plan shall include a test program summary, the test schedule, data quality objectives, and both an internal and external quality assurance (QA) program. Data quality objectives are the pretest expectations of precision, accuracy, and completeness of data.

(ii) The internal QA program shall include, at a minimum, the activities planned by routine operators and analysts to provide an assessment of test data precision; an example of internal QA is the sampling and analysis of replicate samples.

(iii) The performance testing shall include a test method performance audit (PA) during the performance test. The PAs consist of blind audit samples supplied by an accredited audit sample provider and analyzed during the performance test in order to provide a measure of test data bias. Gaseous audit samples are designed to audit the performance of the sampling system as well as the analytical system and must be collected by the sampling system during the compliance test just as the compliance samples are collected. If a liquid or solid audit sample is designed to audit the sampling system, it must also be collected by the sampling system during the compliance test. If multiple sampling systems or sampling trains are used during the compliance test for any of the test methods, the tester is only required to use one of the sampling systems per method to collect the audit sample. The audit sample must be analyzed by the same analyst using the same analytical reagents and analytical system and at the same time as the compliance samples. Retests are required when there is a failure to produce acceptable results for an audit sample. However, if the audit results do not affect the compliance or noncompliance status of the affected facility, the compliance authority may waive the reanalysis requirement, further audits, or retests and accept the results of the compliance test. Acceptance of the test results shall constitute a waiver of the reanalysis requirement, further audits, or retests. The compliance authority may also use the audit sample failure and the compliance test results as evidence to determine the compliance or noncompliance status of the affected facility. A blind audit sample is a sample whose value is known only to the sample provider and is not revealed to the tested facility until after they report the measured value of the audit sample. For pollutants that exist in the gas phase at ambient temperature, the audit sample shall consist of an appropriate concentration of the pollutant in air or nitrogen that can be introduced into the sampling system of the test method at or near the same entry point as a sample from the emission source. If no gas phase audit samples are available, an acceptable alternative is a sample of the pollutant in the same matrix that would be produced when the sample is recovered from the sampling system as required by the test method. For samples that exist only in a liquid or solid form at ambient temperature, the audit sample shall consist of an appropriate concentration of the pollutant in the same matrix that would be produced when the sample is recovered from the sampling system as required by the test method. An accredited audit sample provider (AASP) is an organization that has been accredited to prepare audit samples by an independent, third party accrediting body.

(A) The source owner, operator, or representative of the tested facility shall obtain an audit sample, if commercially available, from an AASP for each test method used for regulatory compliance purposes. No audit samples are required for the following test methods: Methods 3A and 3C of appendix A-3 of part 60 of this chapter; Methods 6C, 7E, 9, and 10 of appendix A-4 of part 60; Methods 18 and 19 of appendix A-6 of part 60; Methods 20, 22, and 25A of appendix A-7 of part 60; Methods 30A and 30B of appendix A-8 of part 60; and Methods 303, 318, 320, and 321 of appendix A of this part. If multiple sources at a single facility are tested during a compliance test event, only one audit sample is required for each method used during a compliance test. The compliance authority responsible for the compliance test may waive the requirement to include an audit sample if they believe that an audit sample is not necessary. “Commercially available” means that two or more independent AASPs have blind audit samples available for purchase. If the source owner, operator, or representative cannot find an audit sample for a specific method, the owner, operator, or representative shall consult the EPA Web site at the following URL, www.epa.gov/ttn/emc, to confirm whether there is a source that can supply an audit sample for that method. If the EPA Web site does not list an available audit sample at least 60 days prior to the beginning of the compliance test, the source owner, operator, or representative shall not be required to include an audit sample as part of the quality assurance program for the compliance test. When ordering an audit sample, the source owner, operator, or representative shall give the sample provider an estimate for the concentration of each pollutant that is emitted by the source or the estimated concentration of each pollutant based on the permitted level and the name, address, and phone number of the compliance authority. The source owner, operator, or representative shall report the results for the audit sample along with a summary of the emission test results for the audited pollutant to the compliance authority and shall report the results of the audit sample to the AASP. The source owner, operator, or representative shall make both reports at the same time and in the same manner or shall report to the compliance authority first and then report to the AASP. If the method being audited is a method that allows the samples to be analyzed in the field and the tester plans to analyze the samples in the field, the tester may analyze the audit samples prior to collecting the emission samples provided a representative of the compliance authority is present at the testing site. The tester may request, and the compliance authority may grant, a waiver to the requirement that a representative of the compliance authority must be present at the testing site during the field analysis of an audit sample. The source owner, operator, or representative may report the results of the audit sample to the compliance authority and then report the results of the audit sample to the AASP prior to collecting any emission samples. The test protocol and final test report shall document whether an audit sample was ordered and utilized and the pass/fail results as applicable.

(B) An AASP shall have and shall prepare, analyze, and report the true value of audit samples in accordance with a written technical criteria document that describes how audit samples will be prepared and distributed in a manner that will ensure the integrity of the audit sample program. An acceptable technical criteria document shall contain standard operating procedures for all of the following operations:

(1) Preparing the sample;

(2) Confirming the true concentration of the sample;

(3) Defining the acceptance limits for the results from a well qualified tester. This procedure must use well established statistical methods to analyze historical results from well qualified testers. The acceptance limits shall be set so that there is 95 percent confidence that 90 percent of well qualified labs will produce future results that are within the acceptance limit range;

(4) Providing the opportunity for the compliance authority to comment on the selected concentration level for an audit sample;

(5) Distributing the sample to the user in a manner that guarantees that the true value of the sample is unknown to the user;

(6) Recording the measured concentration reported by the user and determining if the measured value is within acceptable limits;

(7) Reporting the results from each audit sample in a timely manner to the compliance authority and to the source owner, operator, or representative by the AASP. The AASP shall make both reports at the same time and in the same manner or shall report to the compliance authority first and then report to the source owner, operator, or representative. The results shall include the name of the facility tested, the date on which the compliance test was conducted, the name of the company performing the sample collection, the name of the company that analyzed the compliance samples including the audit sample, the measured result for the audit sample, and whether the testing company passed or failed the audit. The AASP shall report the true value of the audit sample to the compliance authority. The AASP may report the true value to the source owner, operator, or representative if the AASP's operating plan ensures that no laboratory will receive the same audit sample twice.

(8) Evaluating the acceptance limits of samples at least once every two years to determine in consultation with the voluntary consensus standard body if they should be changed.

(9) Maintaining a database, accessible to the compliance authorities, of results from the audit that shall include the name of the facility tested, the date on which the compliance test was conducted, the name of the company performing the sample collection, the name of the company that analyzed the compliance samples including the audit sample, the measured result for the audit sample, the true value of the audit sample, the acceptance range for the measured value, and whether the testing company passed or failed the audit.

(C) The accrediting body shall have a written technical criteria document that describes how it will ensure that the AASP is operating in accordance with the AASP technical criteria document that describes how audit samples are to be prepared and distributed. This document shall contain standard operating procedures for all of the following operations:

(1) Checking audit samples to confirm their true value as reported by the AASP.

(2) Performing technical systems audits of the AASP's facilities and operating procedures at least once every two years.

(3) Providing standards for use by the voluntary consensus standard body to approve the accrediting body that will accredit the audit sample providers.

(D) The technical criteria documents for the accredited sample providers and the accrediting body shall be developed through a public process guided by a voluntary consensus standards body (VCSB). The VCSB shall operate in accordance with the procedures and requirements in the Office of Management and Budget Circular A-119. A copy of Circular A-119 is available upon request by writing the Office of Information and Regulatory Affairs, Office of Management and Budget, 725 17th Street, NW., Washington, DC 20503, by calling (202) 395-6880 or downloading online at http://standards.gov/standards_gov/a119.cfm. The VCSB shall approve all accrediting bodies. The Administrator will review all technical criteria documents. If the technical criteria documents do not meet the minimum technical requirements in paragraphs (c)(2)(iii)(B) through (C) of this section, the technical criteria documents are not acceptable and the proposed audit sample program is not capable of producing audit samples of sufficient quality to be used in a compliance test. All acceptable technical criteria documents shall be posted on the EPA Web site at the following URL, http://www.epa.gov/ttn/emc.

(iv) The owner or operator of an affected source shall submit the site-specific test plan to the Administrator upon the Administrator's request at least 60 calendar days before the performance test is scheduled to take place, that is, simultaneously with the notification of intention to conduct a performance test required under paragraph (b) of this section, or on a mutually agreed upon date.

(v) The Administrator may request additional relevant information after the submittal of a site-specific test plan.

(3) Approval of site-specific test plan.

(i) The Administrator will notify the owner or operator of approval or intention to deny approval of the site-specific test plan (if review of the site-specific test plan is requested) within 30 calendar days after receipt of the original plan and within 30 calendar days after receipt of any supplementary information that is submitted under paragraph (c)(3)(i)(B) of this section. Before disapproving any site-specific test plan, the Administrator will notify the applicant of the Administrator's intention to disapprove the plan together with—

(A) Notice of the information and findings on which the intended disapproval is based; and

(B) Notice of opportunity for the owner or operator to present, within 30 calendar days after he/she is notified of the intended disapproval, additional information to the Administrator before final action on the plan.

(ii) In the event that the Administrator fails to approve or disapprove the site-specific test plan within the time period specified in paragraph (c)(3)(i) of this section, the following conditions shall apply:

(A) If the owner or operator intends to demonstrate compliance using the test method(s) specified in the relevant standard or with only minor changes to those tests methods (see paragraph (e)(2)(i) of this section), the owner or operator must conduct the performance test within the time specified in this section using the specified method(s);

(B) If the owner or operator intends to demonstrate compliance by using an alternative to any test method specified in the relevant standard, the owner or operator is authorized to conduct the performance test using an alternative test method after the Administrator approves the use of the alternative method when the Administrator approves the site-specific test plan (if review of the site-specific test plan is requested) or after the alternative method is approved (see paragraph (f) of this section). However, the owner or operator is authorized to conduct the performance test using an alternative method in the absence of notification of approval 45 days after submission of the site-specific test plan or request to use an alternative method. The owner or operator is authorized to conduct the performance test within 60 calendar days after he/she is authorized to demonstrate compliance using an alternative test method. Notwithstanding the requirements in the preceding three sentences, the owner or operator may proceed to conduct the performance test as required in this section (without the Administrator's prior approval of the site-specific test plan) if he/she subsequently chooses to use the specified testing and monitoring methods instead of an alternative.

(iii) Neither the submission of a site-specific test plan for approval, nor the Administrator's approval or disapproval of a plan, nor the Administrator's failure to approve or disapprove a plan in a timely manner shall—

(A) Relieve an owner or operator of legal responsibility for compliance with any applicable provisions of this part or with any other applicable Federal, State, or local requirement; or

(B) Prevent the Administrator from implementing or enforcing this part or taking any other action under the Act.

§ 63.8 Monitoring requirements.

(d) Quality control program.

(1) The results of the quality control program required in this paragraph will be considered by the Administrator when he/she determines the validity of monitoring data.

(2) The owner or operator of an affected source that is required to use a CMS and is subject to the monitoring requirements of this section and a relevant standard shall develop and implement a CMS quality control program. As part of the quality control program, the owner or operator shall develop and submit to the Administrator for approval upon request a site-specific performance evaluation test plan for the CMS performance evaluation required in paragraph (e)(3)(i) of this section, according to the procedures specified in paragraph (e). In addition, each quality control program shall include, at a minimum, a written protocol that describes procedures for each of the following operations:

(i) Initial and any subsequent calibration of the CMS;

(ii) Determination and adjustment of the calibration drift of the CMS;

(iii) Preventive maintenance of the CMS, including spare parts inventory;

(iv) Data recording, calculations, and reporting;

(v) Accuracy audit procedures, including sampling and analysis methods; and

(vi) Program of corrective action for a malfunctioning CMS.

(3) The owner or operator shall keep these written procedures on record for the life of the affected source or until the affected source is no longer subject to the provisions of this part, to be made available for inspection, upon request, by the Administrator. If the performance evaluation plan is revised, the owner or operator shall keep previous (i.e., superseded) versions of the performance evaluation plan on record to be made available for inspection, upon request, by the Administrator, for a period of 5 years after each revision to the plan. Where relevant, e.g., program of corrective action for a malfunctioning CMS, these written procedures may be incorporated as part of the affected source's startup, shutdown, and malfunction plan to avoid duplication of planning and recordkeeping efforts.

(e) Performance evaluation of continuous monitoring systems —

(2) Notification of performance evaluation. The owner or operator shall notify the Administrator in writing of the date of the performance evaluation simultaneously with the notification of the performance test date required under § 63.7(b) or at least 60 days prior to the date the performance evaluation is scheduled to begin if no performance test is required.

(g) Reduction of monitoring data.

(1) The owner or operator of each CMS must reduce the monitoring data as specified in paragraphs (g)(1) through (5) of this section.

(2) The owner or operator of each COMS shall reduce all data to 6-minute averages calculated from 36 or more data points equally spaced over each 6-minute period. Data from CEMS for measurement other than opacity, unless otherwise specified in the relevant standard, shall be reduced to 1-hour averages computed from four or more data points equally spaced over each 1-hour period, except during periods when calibration, quality assurance, or maintenance activities pursuant to provisions of this part are being performed. During these periods, a valid hourly average shall consist of at least two data points with each representing a 15-minute period. Alternatively, an arithmetic or integrated 1-hour average of CEMS data may be used. Time periods for averaging are defined in § 63.2.

(3) The data may be recorded in reduced or nonreduced form (e.g., ppm pollutant and percent O2 or ng/J of pollutant).

(4) All emission data shall be converted into units of the relevant standard for reporting purposes using the conversion procedures specified in that standard. After conversion into units of the relevant standard, the data may be rounded to the same number of significant digits as used in that standard to specify the emission limit (e.g., rounded to the nearest 1 percent opacity).

(5) Monitoring data recorded during periods of unavoidable CMS breakdowns, out-of-control periods, repairs, maintenance periods, calibration checks, and zero (low-level) and high-level adjustments must not be included in any data average computed under this part. For the owner or operator complying with the requirements of § 63.10(b)(2)(vii)(A) or (B), data averages must include any data recorded during periods of monitor breakdown or malfunction.

§ 63.9 Notification requirements.

(b) Initial notifications.

(1)

(i) The requirements of this paragraph apply to the owner or operator of an affected source when such source becomes subject to a relevant standard.

(ii) If an area source subsequently becomes a major source that is subject to the emission standard or other requirement, such source shall be subject to the notification requirements of this section. Area sources previously subject to major source requirements that become major sources again are also subject to the notification requirements of this paragraph and must submit the notification according to the requirements of paragraph (k) of this section.

(iii) Affected sources that are required under this paragraph to submit an initial notification may use the application for approval of construction or reconstruction under § 63.5(d) of this subpart, if relevant, to fulfill the initial notification requirements of this paragraph.

(2) The owner or operator of an affected source that has an initial startup before the effective date of a relevant standard under this part shall notify the Administrator in writing that the source is subject to the relevant standard. The notification, which shall be submitted not later than 120 calendar days after the effective date of the relevant standard (or within 120 calendar days after the source becomes subject to the relevant standard), shall provide the following information:

(i) The name and address of the owner or operator;

(ii) The address (i.e., physical location) of the affected source;

(iii) An identification of the relevant standard, or other requirement, that is the basis of the notification and the source's compliance date;

(iv) A brief description of the nature, size, design, and method of operation of the source and an identification of the types of emission points within the affected source subject to the relevant standard and types of hazardous air pollutants emitted; and

(v) A statement of whether the affected source is a major source or an area source.

(3) [Reserved]

(4) The owner or operator of a new or reconstructed major affected source for which an application for approval of construction or reconstruction is required under § 63.5(d) must provide the following information in writing to the Administrator:

(i) A notification of intention to construct a new major-emitting affected source, reconstruct a major-emitting affected source, or reconstruct a major source such that the source becomes a major-emitting affected source with the application for approval of construction or reconstruction as specified in § 63.5(d)(1)(i); and

(ii)-(iv) [Reserved]

(v) A notification of the actual date of startup of the source, delivered or postmarked within 15 calendar days after that date.

(5) The owner or operator of a new or reconstructed affected source for which an application for approval of construction or reconstruction is not required under § 63.5(d) must provide the following information in writing to the Administrator:

(i) A notification of intention to construct a new affected source, reconstruct an affected source, or reconstruct a source such that the source becomes an affected source, and

(ii) A notification of the actual date of startup of the source, delivered or postmarked within 15 calendar days after that date.

(iii) Unless the owner or operator has requested and received prior permission from the Administrator to submit less than the information in § 63.5(d), the notification must include the information required on the application for approval of construction or reconstruction as specified in § 63.5(d)(1)(i).

(c) Request for extension of compliance. If the owner or operator of an affected source cannot comply with a relevant standard by the applicable compliance date for that source, or if the owner or operator has installed BACT or technology to meet LAER consistent with § 63.6(i)(5) of this subpart, he/she may submit to the Administrator (or the State with an approved permit program) a request for an extension of compliance as specified in § 63.6(i)(4) through § 63.6(i)(6).

(d) Notification that source is subject to special compliance requirements. An owner or operator of a new source that is subject to special compliance requirements as specified in § 63.6(b)(3) and § 63.6(b)(4) shall notify the Administrator of his/her compliance obligations not later than the notification dates established in paragraph (b) of this section for new sources that are not subject to the special provisions.

(e) Notification of performance test. The owner or operator of an affected source shall notify the Administrator in writing of his or her intention to conduct a performance test at least 60 calendar days before the performance test is scheduled to begin to allow the Administrator to review and approve the site-specific test plan required under § 63.7(c), if requested by the Administrator, and to have an observer present during the test.

(g) Additional notification requirements for sources with continuous monitoring systems. The owner or operator of an affected source required to use a CMS by a relevant standard shall furnish the Administrator written notification as follows:

(1) A notification of the date the CMS performance evaluation under § 63.8(e) is scheduled to begin, submitted simultaneously with the notification of the performance test date required under § 63.7(b). If no performance test is required, or if the requirement to conduct a performance test has been waived for an affected source under § 63.7(h), the owner or operator shall notify the Administrator in writing of the date of the performance evaluation at least 60 calendar days before the evaluation is scheduled to begin;

(h) Notification of compliance status.

(1) The requirements of paragraphs (h)(2) through (h)(4) of this section apply when an affected source becomes subject to a relevant standard.

(2)

(i) Before a title V permit has been issued to the owner or operator of an affected source, and each time a notification of compliance status is required under this part, the owner or operator of such source shall submit to the Administrator a notification of compliance status, signed by the responsible official who shall certify its accuracy, attesting to whether the source has complied with the relevant standard. The notification shall list—

(A) The methods that were used to determine compliance;

(B) The results of any performance tests, opacity or visible emission observations, continuous monitoring system (CMS) performance evaluations, and/or other monitoring procedures or methods that were conducted;

(C) The methods that will be used for determining continuing compliance, including a description of monitoring and reporting requirements and test methods;

(D) The type and quantity of hazardous air pollutants emitted by the source (or surrogate pollutants if specified in the relevant standard), reported in units and averaging times and in accordance with the test methods specified in the relevant standard;

(E) If the relevant standard applies to both major and area sources, an analysis demonstrating whether the affected source is a major source (using the emissions data generated for this notification);

(F) A description of the air pollution control equipment (or method) for each emission point, including each control device (or method) for each hazardous air pollutant and the control efficiency (percent) for each control device (or method); and

(G) A statement by the owner or operator of the affected existing, new, or reconstructed source as to whether the source has complied with the relevant standard or other requirements.

(ii) The notification must be sent before the close of business on the 60th day following the completion of the relevant compliance demonstration activity specified in the relevant standard (unless a different reporting period is specified in the standard, in which case the letter must be sent before the close of business on the day the report of the relevant testing or monitoring results is required to be delivered or postmarked). For example, the notification shall be sent before close of business on the 60th (or other required) day following completion of the initial performance test and again before the close of business on the 60th (or other required) day following the completion of any subsequent required performance test. If no performance test is required but opacity or visible emission observations are required to demonstrate compliance with an opacity or visible emission standard under this part, the notification of compliance status shall be sent before close of business on the 30th day following the completion of opacity or visible emission observations. Notifications may be combined as long as the due date requirement for each notification is met.

(3) After a title V permit has been issued to the owner or operator of an affected source, the owner or operator of such source shall comply with all requirements for compliance status reports contained in the source's title V permit, including reports required under this part. After a title V permit has been issued to the owner or operator of an affected source, and each time a notification of compliance status is required under this part, the owner or operator of such source shall submit the notification of compliance status to the appropriate permitting authority following completion of the relevant compliance demonstration activity specified in the relevant standard.

(4) [Reserved]

(5) If an owner or operator of an affected source submits estimates or preliminary information in the application for approval of construction or reconstruction required in § 63.5(d) in place of the actual emissions data or control efficiencies required in paragraphs (d)(1)(ii)(H) and (d)(2) of § 63.5, the owner or operator shall submit the actual emissions data and other correct information as soon as available but no later than with the initial notification of compliance status required in this section.

(6) Advice on a notification of compliance status may be obtained from the Administrator.

(j) Change in information already provided. Any change in the information already provided under this section shall be provided to the Administrator within 15 calendar days after the change. The owner or operator of a major source that reclassifies to area source status is also subject to the notification requirements of this paragraph. The owner or operator may use the application for reclassification with the regulatory authority (e.g., permit application) to fulfill the requirements of this paragraph. A source which reclassified after January 25, 2018, and before January 19, 2021, and has not yet provided the notification of a change in information is required to provide such notification no later than February 2, 2021, according to the requirements of paragraph (k) of this section. Beginning January 19, 2021, the owner or operator of a major source that reclassifies to area source status must submit the notification according to the requirements of paragraph (k) of this section. A notification of reclassification must contain the following information:

(1) The name and address of the owner or operator;

(2) The address (i.e., physical location) of the affected source;

(3) An identification of the standard being reclassified from and to (if applicable); and

(4) Date of effectiveness of the reclassification.

§ 63.10 Recordkeeping and reporting requirements.

(b) General recordkeeping requirements.

(1) The owner or operator of an affected source subject to the provisions of this part shall maintain files of all information (including all reports and notifications) required by this part recorded in a form suitable and readily available for expeditious inspection and review. The files shall be retained for at least 5 years following the date of each occurrence, measurement, maintenance, corrective action, report, or record. At a minimum, the most recent 2 years of data shall be retained on site. The remaining 3 years of data may be retained off site. Such files may be maintained on microfilm, on a computer, on computer floppy disks, on magnetic tape disks, or on microfiche.

(2) The owner or operator of an affected source subject to the provisions of this part shall maintain relevant records for such source of—

(i) The occurrence and duration of each startup or shutdown when the startup or shutdown causes the source to exceed any applicable emission limitation in the relevant emission standards;

(ii) The occurrence and duration of each malfunction of operation (i.e., process equipment) or the required air pollution control and monitoring equipment;

(iii) All required maintenance performed on the air pollution control and monitoring equipment;

(iv)

(A) Actions taken during periods of startup or shutdown when the source exceeded applicable emission limitations in a relevant standard and when the actions taken are different from the procedures specified in the affected source's startup, shutdown, and malfunction plan (see § 63.6(e)(3)); or

(B) Actions taken during periods of malfunction (including corrective actions to restore malfunctioning process and air pollution control and monitoring equipment to its normal or usual manner of operation) when the actions taken are different from the procedures specified in the affected source's startup, shutdown, and malfunction plan (see § 63.6(e)(3));

(v) All information necessary, including actions taken, to demonstrate conformance with the affected source's startup, shutdown, and malfunction plan (see § 63.6(e)(3)) when all actions taken during periods of startup or shutdown (and the startup or shutdown causes the source to exceed any applicable emission limitation in the relevant emission standards), and malfunction (including corrective actions to restore malfunctioning process and air pollution control and monitoring equipment to its normal or usual manner of operation) are consistent with the procedures specified in such plan. (The information needed to demonstrate conformance with the startup, shutdown, and malfunction plan may be recorded using a “checklist,” or some other effective form of recordkeeping, in order to minimize the recordkeeping burden for conforming events);

(vi) Each period during which a CMS is malfunctioning or inoperative (including out-of-control periods);

(vii) All required measurements needed to demonstrate compliance with a relevant standard (including, but not limited to, 15-minute averages of CMS data, raw performance testing measurements, and raw performance evaluation measurements, that support data that the source is required to report);

(A) This paragraph applies to owners or operators required to install a continuous emissions monitoring system (CEMS) where the CEMS installed is automated, and where the calculated data averages do not exclude periods of CEMS breakdown or malfunction. An automated CEMS records and reduces the measured data to the form of the pollutant emission standard through the use of a computerized data acquisition system. In lieu of maintaining a file of all CEMS subhourly measurements as required under paragraph (b)(2)(vii) of this section, the owner or operator shall retain the most recent consecutive three averaging periods of subhourly measurements and a file that contains a hard copy of the data acquisition system algorithm used to reduce the measured data into the reportable form of the standard.

(B) This paragraph applies to owners or operators required to install a CEMS where the measured data is manually reduced to obtain the reportable form of the standard, and where the calculated data averages do not exclude periods of CEMS breakdown or malfunction. In lieu of maintaining a file of all CEMS subhourly measurements as required under paragraph (b)(2)(vii) of this section, the owner or operator shall retain all subhourly measurements for the most recent reporting period. The subhourly measurements shall be retained for 120 days from the date of the most recent summary or excess emission report submitted to the Administrator.

(C) The Administrator or delegated authority, upon notification to the source, may require the owner or operator to maintain all measurements as required by paragraph (b)(2)(vii), if the administrator or the delegated authority determines these records are required to more accurately assess the compliance status of the affected source.

(viii) All results of performance tests, CMS performance evaluations, and opacity and visible emission observations;

(ix) All measurements as may be necessary to determine the conditions of performance tests and performance evaluations;

(x) All CMS calibration checks;

(xi) All adjustments and maintenance performed on CMS;

(xii) Any information demonstrating whether a source is meeting the requirements for a waiver of recordkeeping or reporting requirements under this part, if the source has been granted a waiver under paragraph (f) of this section;

(xiii) All emission levels relative to the criterion for obtaining permission to use an alternative to the relative accuracy test, if the source has been granted such permission under § 63.8(f)(6); and

(xiv) All documentation supporting initial notifications and notifications of compliance status under § 63.9.

(3) If an owner or operator determines that his or her existing or new stationary source is in the source category regulated by a standard established pursuant to section 112 of the Act, but that source is not subject to the relevant standard (or other requirement established under this part) because of enforceable limitations on the source's potential to emit, or the source otherwise qualifies for an exclusion, the owner or operator must keep a record of the applicability determination. The applicability determination must be kept on site at the source for a period of 5 years after the determination, or until the source changes its operations to become an affected source subject to the relevant standard (or other requirement established under this part), whichever comes first if the determination is made prior to January 19, 2021. The applicability determination must be kept until the source changes its operations to become an affected source subject to the relevant standard (or other requirement established under this part) if the determination was made on or after January 19, 2021. The record of the applicability determination must be signed by the person making the determination and include an emissions analysis (or other information) that demonstrates the owner or operator's conclusion that the source is unaffected (e.g., because the source is an area source). The analysis (or other information) must be sufficiently detailed to allow the Administrator to make an applicability finding for the source with regard to the relevant standard or other requirement. If applicable, the analysis must be performed in accordance with requirements established in relevant subparts of this part for this purpose for particular categories of stationary sources. If relevant, the analysis should be performed in accordance with EPA guidance materials published to assist sources in making applicability determinations under section 112 of the Act, if any. The requirements to determine applicability of a standard under § 63.1(b)(3) and to record the results of that determination under this paragraph (b)(3) of this section shall not by themselves create an obligation for the owner or operator to obtain a title V permit.

(d) General reporting requirements.

(2) Reporting results of performance tests. Before a title V permit has been issued to the owner or operator of an affected source, the owner or operator shall report the results of any performance test under § 63.7 to the Administrator. After a title V permit has been issued to the owner or operator of an affected source, the owner or operator shall report the results of a required performance test to the appropriate permitting authority. The owner or operator of an affected source shall report the results of the performance test to the Administrator (or the State with an approved permit program) before the close of business on the 60th day following the completion of the performance test, unless specified otherwise in a relevant standard or as approved otherwise in writing by the Administrator. The results of the performance test shall be submitted as part of the notification of compliance status required under § 63.9(h).

§ 63.8570 What are my general requirements for complying with this subpart?

(d) If you own or operate an affected source that is subject to the emission limits specified in Table 1 to this subpart and must perform routine maintenance on the control device for that affected source, you may bypass the source control device and continue operating the affected source subject to the alternative standard established in this paragraph upon approval by the Administrator and provided you satisfy the conditions listed in paragraphs (d)(1) through (5) of this section.

(1) You must request to use the routine control device maintenance alternative standard from the Administrator no later than 120 calendar days before the compliance date specified in § 63.8545. Your request must justify the need for the routine maintenance on the control device and the time required to accomplish the maintenance activities, describe the maintenance activities and the frequency of the maintenance activities, explain why the maintenance cannot be accomplished during source shutdowns, provide information stating whether the continued operation of the affected source will result in fewer emissions than shutting the source down while the maintenance is performed, describe how you plan to comply with paragraph (b) of this section during the maintenance, and provide any other documentation required by the Administrator.

(2) The routine control device maintenance must not exceed 4 percent of the annual operating uptime for each affected source.

(3) The request for the routine control device maintenance alternative standard, if approved by the Administrator, must be incorporated by reference in and attached to the affected source's title V permit.

(4) You must minimize HAP emissions during the period when the affected source is operating and the control device is offline by complying with the applicable standard in Table 3 to this subpart.

(5) You must minimize the time period during which the affected source is operating and the control device is offline.

§ 63.8630 What notifications must I submit and when?

(a) You must submit all of the notifications in §§ 63.7(b) and (c), 63.8(f)(4), and 63.9 (b) through (e), (g)(1), and (h) that apply to you, by the dates specified.

(b) You must submit all of the notifications specified in Table 9 to this subpart that apply to you, by the dates specified.

(c) If you are required to conduct a performance test or other initial compliance demonstration as specified in Tables 4 and 6 to this subpart, your Notification of Compliance Status as specified in Table 9 to this subpart must include the information in paragraphs (c)(1) through (4) of this section.

(1) The requirements in § 63.9(h)(2)(i).

(2) The operating limit parameter values established for each affected source with supporting documentation and a description of the procedure used to establish the values.

(3) For each APCD that includes a fabric filter, if a bag leak detection system is used, analysis and supporting documentation demonstrating conformance with EPA guidance and specifications for bag leak detection systems in § 63.8600(e).

(4) Identification of whether you plan to demonstrate compliance by emissions averaging. If you plan to demonstrate compliance by emissions averaging, report the emissions level that was being achieved or the control technology employed on December 28, 2015.

(d) If you own or operate an affected kiln that is subject to the work practice standard specified in Item 1 of Table 3 to this subpart, and you intend to use a fuel other than natural gas or equivalent to fire the affected kiln, your notification of alternative fuel use must include the information specified in paragraphs (d)(1) through (5) of this section.

(1) Company name and address.

(2) Identification of the affected kiln.

(3) Reason you are unable to use natural gas or equivalent fuel, including the date when the natural gas curtailment was declared or the natural gas supply interruption began.

(4) Type of alternative fuel that you intend to use.

(5) Dates when the alternative fuel use is expected to begin and end.

§ 63.8635 What reports must I submit and when?

(a) You must submit each report in Table 10 to this subpart that applies to you.

(b) Unless the Administrator has approved a different schedule for submission of reports under § 63.10(a), you must submit each report by the date in Table 10 to this subpart and as specified in paragraphs (b)(1) through (5) of this section.

(1) The first compliance report must cover the period beginning on the compliance date that is specified for your affected source in § 63.8545 and ending on either June 30 or December 31. This reporting period must be at least 6 months, but less than 12 months. For example, if your compliance date is March 1, then the first semiannual reporting period would begin on March 1 and end on December 31.

(2) The first compliance report must be postmarked or delivered no later than July 31 or January 31 for compliance periods ending on June 30 and December 31, respectively.

(3) Each subsequent compliance report must cover the semiannual reporting period from January 1 through June 30 or the semiannual reporting period from July 1 through December 31.

(4) Each subsequent compliance report must be postmarked or delivered no later than July 31 or January 31 for compliance periods ending on June 30 and December 31, respectively.

(5) For each affected source that is subject to permitting regulations pursuant to 40 CFR part 70 or 40 CFR part 71, and if the permitting authority has established dates for submitting semiannual reports pursuant to 40 CFR 70.6(a)(3)(iii)(A) or 40 CFR 71.6(a)(3)(iii)(A), you may submit the first and subsequent compliance reports according to the dates the permitting authority has established instead of the dates in paragraphs (b)(1) through (4) of this section.

(c) The compliance report must contain the information in paragraphs (c)(1) through (9) of this section.

(1) Company name and address.

(2) Statement by a responsible official with that official's name, title, and signature, certifying that, based on information and belief formed after reasonable inquiry, the statements and information in the report are true, accurate, and complete.

(3) Date of report and beginning and ending dates of the reporting period.

(4) A description of control device maintenance performed while the control device was offline and the affected source controlled by the control device was operating, including the information specified in paragraphs (c)(4)(i) through (iii) of this section.

(i) The date and time when the control device was shut down and restarted.

(ii) Identification of the affected source that was operating and the number of hours that the affected source operated while the control device was offline.

(iii) A statement of whether or not the control device maintenance was included in your approved routine control device maintenance request developed as specified in § 63.8570(d). If the control device maintenance was included in your approved routine control device maintenance request, then you must report the information in paragraphs (c)(4)(iii)(A) through (C) of this section.

(A) The total amount of time that the affected source controlled by the control device operated during the current semiannual compliance period and during the previous semiannual compliance period.

(B) The amount of time that each affected source controlled by the control device operated while the control device was offline for maintenance covered under the routine control device maintenance alternative standard during the current semiannual compliance period and during the previous semiannual compliance period.

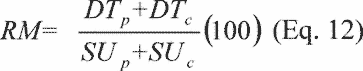

(C) Based on the information recorded under paragraphs (c)(4)(iii)(A) and (B) of this section, compute the annual percent of affected source operating uptime during which the control device was offline for routine maintenance using Equation 12 of this section.

Where:

RM = Annual percentage of affected source uptime during which control device was offline for routine control device maintenance.

DTp = Control device downtime claimed under the routine control device maintenance alternative standard for the previous semiannual compliance period.

DTc = Control device downtime claimed under the routine control device maintenance alternative standard for the current semiannual compliance period.

SUp = Affected source uptime for the previous semiannual compliance period.

SUc = Affected source uptime for the current semiannual compliance period.

(5) If there are no deviations from any emission limitations (emission limits or operating limits) or work practice standards that apply to you, the compliance report must contain a statement that there were no deviations from the emission limitations or work practice standards during the reporting period.

(6) If there were no periods during which the CMS was out-of-control as specified in your OM&M plan, the compliance report must contain a statement that there were no periods during which the CMS was out-of-control during the reporting period.

(7) The first compliance report must contain the startup production rate for each ceramic tile roller kiln, floor tile press dryer, ceramic tile spray dryer, and sanitaryware tunnel kiln; the minimum APCD inlet temperature for each APCD; and the temperature profile for each ceramic tile roller kiln, floor tile press dryer, ceramic tile spray dryer, and sanitaryware tunnel kiln without an APCD.

(8) For each deviation that occurs at an affected source, report such events in the compliance report by including the information in paragraphs (c)(8)(i) through (iii) of this section.

(i) The date, time, and duration of the deviation.

(ii) A list of the affected sources or equipment for which the deviation occurred.

(iii) An estimate of the quantity of each regulated pollutant emitted over any emission limit, and a description of the method used to estimate the emissions.

(9) If you plan to demonstrate compliance by emissions averaging, certify the emissions level achieved or the control technology employed is no less stringent than the level or control technology contained in the notification of compliance status in § 63.8630(c)(4), including all necessary documentation to support this certification, such as inputs to Equations 9 through 11 of this subpart.

(d) For each deviation from an emission limitation (emission limit or operating limit) occurring at an affected source where you are using a CMS to comply with the emission limitations in this subpart, you must include the information in paragraphs (c)(1) through (4) and (c)(8), and paragraphs (d)(1) through (11) of this section. This includes periods of startup, shutdown, and routine control device maintenance.

(1) The total operating time of each affected source during the reporting period.

(2) The date and time that each CMS was inoperative, except for zero (low-level) and high-level checks.

(3) The date, time, and duration that each CMS was out-of-control, including the pertinent information in your OM&M plan.

(4) Whether each deviation occurred during routine control device maintenance covered in your approved routine control device maintenance alternative standard or during another period, and the cause of each deviation (including unknown cause, if applicable).

(5) A description of any corrective action taken to return the affected unit to its normal or usual manner of operation.

(6) A breakdown of the total duration of the deviations during the reporting period into those that are due to startup, shutdown, control equipment problems, process problems, other known causes, and other unknown causes.

(7) A summary of the total duration of CMS downtime during the reporting period and the total duration of CMS downtime as a percent of the total source operating time during that reporting period.

(8) A brief description of the process units.

(9) A brief description of the CMS.

(10) The date of the latest CMS certification or audit.

(11) A description of any changes in CMS, processes, or control equipment since the last reporting period.

(e) If you have obtained a title V operating permit according to 40 CFR part 70 or 40 CFR part 71, you must report all deviations as defined in this subpart in the semiannual monitoring report required by 40 CFR 70.6(a)(3)(iii)(A) or 40 CFR 71.6(a)(3)(iii)(A). If you submit a compliance report according to Table 8 to this subpart along with, or as part of, the semiannual monitoring report required by 40 CFR 70.6(a)(3)(iii)(A) or 40 CFR 71.6(a)(3)(iii)(A), and the compliance report includes all required information concerning deviations from any emission limitation (including any operating limit), then submitting the compliance report will satisfy any obligation to report the same deviations in the semiannual monitoring report. However, submitting a compliance report will not otherwise affect any obligation you may have to report deviations from permit requirements to the permitting authority.

(f) If you own or operate an affected kiln that is subject to the work practice standard specified in Item 1 of Table 3 to this subpart, and you use a fuel other than natural gas or equivalent to fire the affected kiln, you must submit a report of alternative fuel use within 10 working days after terminating the use of the alternative fuel. The report must include the information in paragraphs (f)(1) through (6) of this section.

(1) Company name and address.

(2) Identification of the affected kiln.

(3) Reason for using the alternative fuel.

(4) Type of alternative fuel used to fire the affected kiln.

(5) Dates that the use of the alternative fuel started and ended.

(6) Amount of alternative fuel used.

(g) Within 60 calendar days after the date of completing each performance test (as defined in § 63.2) required by this subpart, you must submit the results of the performance test following the procedure specified in either paragraph (g)(1) or (g)(2) of this section.

(1) For data collected using test methods supported by the EPA's Electronic Reporting Tool (ERT) as listed on the EPA's ERT website (https://www.epa.gov/electronic-reporting-air-emissions/electronic-reporting-tool-ert) at the time of the test, you must submit the results of the performance test to the EPA via the Compliance and Emissions Data Reporting Interface (CEDRI). (CEDRI can be accessed through the EPA's Central Data Exchange (CDX) (https://cdx.epa.gov/).) Performance test data must be submitted in a file format generated through the use of the EPA's ERT or an alternate electronic file format consistent with the extensible markup language (XML) schema listed on the EPA's ERT website. If you claim that some of the performance test information being submitted is confidential business information (CBI), you must submit a complete file generated through the use of the EPA's ERT or an alternate electronic file consistent with the XML schema listed on the EPA's ERT website, including information claimed to be CBI, on a compact disc, flash drive, or other commonly used electronic storage media to the EPA. The electronic media must be clearly marked as CBI and mailed to U.S. EPA/OAPQS/CORE CBI Office, Attention: Group Leader, Measurement Policy Group, MD C404-02, 4930 Old Page Rd., Durham, NC 27703. The same ERT or alternate file with the CBI omitted must be submitted to the EPA via the EPA's CDX as described earlier in this paragraph (g)(1).

(2) For data collected using test methods that are not supported by the EPA's ERT as listed on the EPA's ERT Web site at the time of the test, you must submit the results of the performance test to the Administrator at the appropriate address listed in § 63.13.

§ 63.8640 What records must I keep?

(a) You must keep the records listed in paragraphs (a)(1) through (3) of this section.

(1) A copy of each notification and report that you submitted to comply with this subpart, including all documentation supporting any Initial Notification or Notification of Compliance Status that you submitted, according to the requirements in § 63.10(b)(2)(xiv).

(2) Records of performance tests as required in § 63.10(b)(2)(viii).

(3) Records relating to control device maintenance and documentation of your approved routine control device maintenance request, if you request to use the alternative standard under § 63.8570(d).

(b) You must keep the records required in Table 7 to this subpart to show continuous compliance with each emission limitation and work practice standard that applies to you.

(c) You must also maintain the records listed in paragraphs (c)(1) through (11) of this section.

(1) For each bag leak detection system, records of each alarm, the time of the alarm, the time corrective action was initiated and completed, and a brief description of the cause of the alarm and the corrective action taken.

(2) For each deviation, record the information in paragraphs (c)(2)(i) through (iv) of this section.

(i) The date, time, and duration of the deviation.

(ii) A list of the affected sources or equipment.

(iii) An estimate of the quantity of each regulated pollutant emitted over any emission limit and a description of the method used to estimate the emissions.

(iv) Actions taken to minimize emissions in accordance with § 63.8570(b) and any corrective actions taken to return the affected unit to its normal or usual manner of operation.

(3) For each affected source, records of production rates on a ton throughput processed basis.

(4) Records for any approved alternative monitoring or test procedures.

(5) Records of maintenance and inspections performed on the APCD.

(6) Current copies of your OM&M plan, including any revisions, with records documenting conformance.

(7) Logs of the information required in paragraphs (c)(7)(i) through (iii) of this section to document proper operation of your sanitaryware shuttle kiln.

(i) Records of the firing time and temperature cycle for each sanitaryware shuttle kiln. If all shuttle kilns use the same time and temperature cycles, one copy may be maintained for each kiln. Reference numbers must be assigned to use in log sheets.

(ii) For each sanitaryware shuttle kiln, a log that details the time and temperature protocol reference number, and an indication of whether the appropriate time and temperature cycle was fired.

(iii) For each sanitaryware shuttle kiln, a log of the actual tonnage of greenware fired in the shuttle kiln and an indication of whether the tonnage was below the maximum tonnage for that specific kiln.

(8) Logs of the maintenance procedures used to demonstrate compliance with the maintenance requirements of the sanitaryware shuttle kiln work practice standards specified in Table 3 to this subpart.

(9) For periods of startup and shutdown, records of the following information:

(i) The date, time, and duration of each startup and/or shutdown period, recording the periods when the affected source was subject to the standard applicable to startup and shutdown.

(ii) For periods of startup, the production rate and exhaust temperature prior to the time the exhaust reaches the minimum APCD inlet temperature (for ceramic tile roller kilns, floor tile press dryers, ceramic tile spray dryers, and sanitaryware tunnel kilns with an APCD) or the temperature profile is attained (for ceramic tile roller kilns, floor tile press dryers, ceramic tile spray dryers, and sanitaryware tunnel kilns with no APCD).

(iii) For periods of shutdown, the production rate and exhaust temperature after the time the exhaust falls below the minimum APCD inlet temperature (for ceramic tile roller kilns, floor tile press dryers, ceramic tile spray dryers, and sanitaryware tunnel kilns with an APCD) or the temperature profile is no longer maintained (for ceramic tile roller kilns, floor tile press dryers, ceramic tile spray dryers, and sanitaryware tunnel kilns with no APCD).

(10) All site-specific parameters, temperature profiles, and procedures required to be established or developed according to the applicable work practice standards in Table 3 to this subpart.

(11) If you elect to average emissions consistent with § 63.8595(h), you must additionally keep a copy of the emissions averaging implementation plan required in § 63.8595(h)(5), all calculations required under § 63.8595(h), including monthly records of process rate, as applicable, and monitoring records consistent with § 63.8620(f).

§ 63.8645 In what form and for how long must I keep my records?

(a) Your records must be in a form suitable and readily available for expeditious review, according to § 63.10(b)(1).

(b) As specified in § 63.10(b)(1), you must keep each record for 5 years following the date of each occurrence, measurement, maintenance, corrective action, report, or record.

(c) You must keep each record onsite for at least 2 years after the date of each occurrence, measurement, maintenance, corrective action, report, or record, according to § 63.10(b)(1). You may keep the records offsite for the remaining 3 years.

| File Type | application/vnd.openxmlformats-officedocument.wordprocessingml.document |

| Author | ERG |

| File Modified | 0000-00-00 |

| File Created | 2025-03-01 |

© 2026 OMB.report | Privacy Policy