GC-859 Nuclear Fuel Data Survey

GC-859 Nuclear Fuel Data Survey

2023-Form_GC859_Survey_ Final_20230411

OMB: 1901-0287

![]()

FORM GC-859 NUCLEAR FUEL DATA SURVEY

OMB NO. xxxx-xxxx Expiration Date: xx/xx/xxxx

Burden: 90 Hours

Legislative Authority: Data on this mandatory form are collected under authority of the Federal Energy Administration Act of 1974 (15 USC Schedule 761 et seq.), Department of Energy Organization Act (42 USC 7101 et seq.), and the Nuclear Waste Policy Act of 1982, as amended (42 USC 10101 et seq.). Failure to file after receiving notification from Pacific Northwest National Laboratory (PNNL) on behalf of the U.S. Department of Energy may result in criminal fines, civil penalties and other sanctions as provided by the law. Data being collected on this form are not considered to be confidential.

Title 18 U.S.C. 1001 makes it a criminal offense for any person knowingly and willingly to make to any Agency or Department of the United States any false, fictitious, or fraudulent statements as to any matter within its jurisdiction. Information regarding security measures or material control and accounting procedures is not solicited; inclusion of such information in this data call is specifically prohibited.

Public Reporting Burden: The public reporting burden for this collection of information is estimated to average 90 hours per response. The estimate by respondent category is 100 hours per response for operating nuclear reactors, 60 hours per response for permanently shutdown nuclear reactors, and 40 hours per response for storage facilities and research/test reactors. The estimate includes the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing this burden, to the Energy Information Administration, Office of Survey Development and Statistical Integration, EI-21, 1000 Independence Avenue, S.W., Washington, DC 20585, and to the Office of Information and Regulatory Affairs, Office of Management and Budget, 735 17th Street, N.W., Washington, DC 20503. Alternatively, comments can be made through the website or emailed to gc859help@pnnl.gov.

Form Due Date: This form shall be submitted by September 30, 2023. Unless otherwise indicated, data on the form should reflect the spent fuel discharged from January 1, 2018 - December 31, 2022.

Voluntary Data: Schedule C.1.2 Fuel Cycle History is not mandatory.

PNNL Contacts: Refer all questions to the PNNL GC-859 Survey Team at (509) 375-3976, by email to gc859help@pnnl.gov, by message through the website, or by mail to:

Battelle for the USDOE

Attn: GC-859 Survey Team, MSIN K9-89

902 Battelle Blvd

Richland, WA 99354

Please use the following website to submit your data: https://gc859.pnnl.gov

Alternatively, you may request a copy from the PNNL GC-859 Survey Team contact.

RESPONDENT IDENTIFICATION

Site

Operator Name:

Site

Operator Name:

REPORT PERIOD |

|

Begin Report Period: January 1, 2018 End Report Period: December 31, 2022 |

If this is a resubmission, insert X in this block |

|

If there are no data changes from the previous GC-859 submission, insert X in this block |

SCHEDULE A: SITE OPERATOR DATA

See Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes.”

Reactor Identifier |

Reactor Name |

|

|

|

|

|

|

|

|

|

|

List all spent fuel storage facilities being covered by this report.

See Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes.”

Storage Facility Identifier |

Storage Facility Name |

|

|

|

|

|

|

Provide a site operator point of contact for verification of information provided on this form.

Name: Title: Mailing Address:

City: State: Zip Code: Telephone Number: Email:

I certify as a cognizant individual that the historical information contained herein and in any associated electronic media supplied and other materials appended hereto are true and accurate to the best of my knowledge. (NOTE: Corporate Officer signature is not required, but the signatory must be appropriately authorized.)

Name: Title: Signature: Date:

COMMENTS

Provide any comments you have concerning Site Operator Data (Section A.1, A.2, A.3) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

SCHEDULE B: REACTOR DATA

Complete a Schedule B.1 for each reactor, including operating and shutdown reactors. Provide a reactor point of contact for verification of information provided on this form.

If

the person

is also

the site

operator point

of contact,

insert X

in this

block.

If

the person

is also

the site

operator point

of contact,

insert X

in this

block.

Name:

Title:

Mailing Address:

City: State: Zip Code:

Telephone Number:

Email:

Complete a Schedule B.2 for each reactor, including operating and shutdown reactors.

(See Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes.”)

NRC License Expiration Date (MM/DD/YYYY): / /

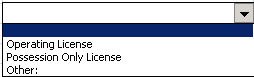

Provide the expiration date of the reactor’s NRC operating license as of the end of the reporting period for this data submission. If the reactor is permanently shutdown, provide the expiration date of the NRC possession only license.

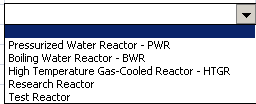

Reactor

Type:

Reactor

Type:

COMMENTS

Provide any comments you have concerning Reactor Data (Section B.1, B.2) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Provide the following data for all operating cycles.

The first cycle of a reactor's operations is designated 01 and successive cycles are numbered consecutively. Operating cycles covered by this report should continue the sequential cycle numbering listed in the previous reporting period, which are provided.

If the reactor has experienced an outage in the midst of a cycle where fuel assemblies were temporarily or permanently discharged, indicate by providing subcycle numbers and start up and shutdown dates as if the subcycle were a complete cycle. Designate subcycles as a, b, c, etc. (example 16a, 16b, 16c). If no fuel assemblies were discharged, simply report the cycle number, start up and shutdown dates without regard to subcycles.

-

Cycle Number

Start Up Date (MM/DD/YYYY)

Shutdown Date (MM/DD/YYYY)

COMMENTS

Provide any comments you have concerning Reactor Data (Section B.3) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

SCHEDULE C: FUEL DATA

The Form GC-859 survey collects data on an assembly-specific basis to ensure that all owners have been properly allocated spent nuclear fuel acceptance capacity in the Acceptance Priority Ranking & Annual Capacity Report (APR/ACR). For this reason, respondents are requested to report all discharged fuel including spent nuclear fuel that has been shipped/transferred to another storage site location. Report permanently discharged fuel only. If you are not certain if an assembly will be reinserted, prioritization rules suggest that this is in the utility’s interest to report it as permanently discharged (and modify the total burnup, last cycle number, and last cycle shutdown date later if the assembly is subsequently reinserted).

The assembly specific data to be reported in C.1.1 are as follows:

-

Column

Data Element

Description

1

I

Assembly Identifier

The unique operator-assigned identifier or the American National Standards Institute (ANSI) identifier. The identifier indicated as the “Primary” assembly identifier should be used throughout the survey form.

2 I

Initial Heavy Metal Content

The initial heavy metal content (uranium) of the fuel assembly in kilograms (reported to the nearest thousandth of a kilogram).

3 I

Initial Enrichment

The initial enrichment of the assembly (reported to the nearest hundredth of a percent). Report the maximum Planar-Average Initial Enrichment.

4

Mixed Oxide Fuel Data

Check box and report MOX data (plutonium) in comments, if necessary.

5

Discharge Burnup

The assembly burnup at discharge (reported in megawatt days thermal per metric ton of (initially loaded) uranium (MWDt/MTU)).

6

Last Cycle Number

The cycle number (including subcycles) for the assembly’s final cycle of irradiation.

7

Fuel Assembly Type Code

Select the Fuel Assembly Type Code for each assembly from the dropdown menu and Appendix E.

Alternatively, respondents can use Schedule C.1.3 to report Fuel Assembly Type Codes by cycle and fuel batch. See Schedule C.1.3 for instructions.

8

Assembly Status

Check the appropriate status indicators from the following table. Check all that apply.

Status

Identifier

Description

8A

Non-standard assembly.1, 2

8B

Failed fuel.3

8C

Containerized assembly; the assembly has been placed in a single-element container. Do not report assemblies that have been placed into a multi-element

canister as containerized.

8D

Fuel rods have been removed from the original assembly.

8E

Fueled replacement rods have been inserted into the assembly (8D must also be checked for all 8E assemblies).

-

8F

Stainless steel or other non-fueled replacement rods have been inserted into the assembly (8D must also be checked for all 8F assemblies).

8G

Assembly has special characteristics that do not fall into the previous categories. Provide a description of these characteristics in the comment box.

-

9

Storage Location

The pool or dry storage site identifier (from Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes”) corresponding to the

current storage location of the assembly.

For each assembly in which non-fuel components (NFC) are stored, select each type of non-fuel component. Estimate the weight of the assembly including all the non-fuel components. If the storage of non-fuel components within an assembly classifies that assembly as non-standard according to Appendix E of the Standard Contract, check the Yes box in the Non-standard Assembly column. For example, changes to an assembly’s maximum physical dimensions due to the NFC may cause it to be classified as non-standard. The non-fuel component integral to an assembly specific data to be reported in C.1.1 are as follows:

-

Column

Data Element

Description

10

Non-fuel Component1

The type of non-fuel component that is integral to that assembly.

11

12

Non-fuel Component Identifier

Estimated Total Weight

The alphanumeric characters which identified the non-fuel component that is integral to that assembly.

The estimated total weight of the non-fuel component plus assembly, reported in pounds

1. Standard assembly, non-standard assembly, and non-fuel component as defined in the Standard Contract Appendix E.

2. Respondents need not report assemblies in the spent fuel pool as non-standard if the minimum cooling time (Nonstandard Fuel Class NS-3) is not met as this can be determined by the Last Cycle shutdown date.

3. Failed Fuel Classes F-1 and F-3 are defined in the Standard Contract Appendix E. For Class F-2 Radioactive “Leakage” use the definition consistent with NRC NUREG-1617, Standard Review Plan for Transportation Packages for Spent Nuclear Fuel: “Damaged Spent Nuclear Fuel: spent nuclear fuel with known or suspected cladding defects greater than a hairline crack or a pinhole leak.”

Note: A copy of the Standard Contract is provided in Appendix B.

Report all discharged fuel assemblies and non-fuel components integral to the assembly. See the Table in Section C.1 for descriptions of individual data elements in the table below.

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|||||||

Assembly Identifier |

Initial Heavy Metal Content |

Initial Enrichment (Weight %) |

Mixed Oxide Fuel Data1 |

Discharge Burnup (MWDt/MTU) |

Last Cycle Number |

Fuel Assembly Type Code2 |

Assembly Status Indicators |

Storage Location |

NFC3 |

NFC Identifier |

Estimated Total Weight (lbs) 4 |

|||||||

Non-Standard |

Failed |

Containerized |

Fuel Rod(s) Removed |

Replacement Rods (Fueled) |

Replacement Rods (Non- fueled) |

Other |

||||||||||||

Primary |

Secondary |

kgU |

U-235 |

8A |

8B |

8C |

8D |

8E |

8F |

8G |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 For MOX fuel, please include a comment stating the initial heavy metal content (kgPu) and weight percentage of the plutonium (239Pu and 241Pu).

2 Fuel Assembly Type data selected from Appendix E (drop-down menu) or entered by cycle and fuel batch using Schedule C.1.3.

3 If the assembly has non-fuel components (NFC) stored as an integral part of the assembly, please select the type of non-fuel component(s) from the drop-down menu.

4 Estimated total weight of the non-fuel component(s) plus assembly

.

COMMENTS

Provide any comments you have concerning Data On Discharged Fuel Assemblies and Non-Fuel Components Integral to the Assembly (Section C.1.1) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

For all assemblies irradiated in this reactor, including each assembly listed in Table C.1.1, identify the cycles during which the assembly was irradiated in the reactor core and the cumulative assembly burnup for each cycle. Include data for all discharged assemblies. The Assembly Identifier must match the primary assembly identifier in Section C.1.1 of the current or prior data collection, whichever is applicable.

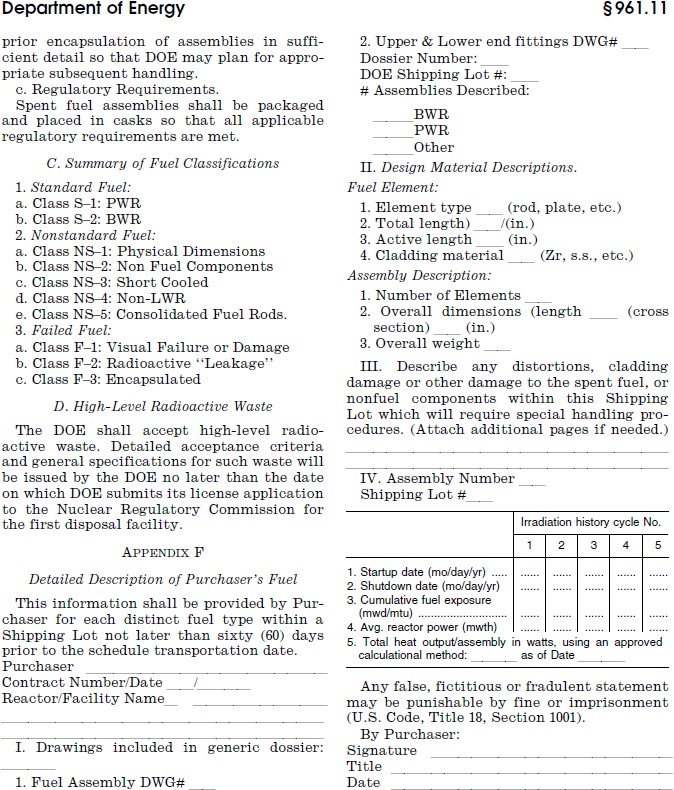

Providing cycle numbers and cumulative burnup data for each assembly is voluntary. To the extent that a respondent provides complete, assembly level cumulative burnup data by cycle number, the utility is considered to have satisfied the utility’s obligation under the Standard Contract for the Disposal of Spent Nuclear Fuel and/or High-Level Radioactive Waste (10 CFR 961) Appendix F - Detailed Description of Purchaser's Fuel subsection IV regarding assembly level “irradiation history.”

-

Assembly Identifier

Reactor Cycle Numbers

Cumulative Burnup for Each Cycle (MWDt/MTU)

COMMENTS

Provide any comments you have concerning Fuel Cycle History (Section C.1.2) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Fuel Assembly Types are used to describe a combination of fuel vendor, lattice size, and fuel features. The Fuel Assembly Type is based on the Oak Ridge National Lab report ORNL/TM- 10901 “A Classification Scheme for LWR Fuel Assemblies” November 1988. Fuel Assembly Type is identified via the use of Fuel Assembly Type Codes which are provided in Appendix E.

Within the GC-859 software, Fuel Assembly Type Code selection is limited to the codes that are appropriate for each individual reactor, so that only a limited number of choices are available.

Because most reloads will consist of only one or two Fuel Assembly Types, C.1.3 simplifies the process by removing the need to report Fuel Assembly Types on an individual assembly basis.

Respondents should report the identification of Fuel Assembly Types for batches of fuel as assemblies are initially loaded into the reactor core. The associated range of assembly IDs and number of assemblies is also requested in order for PNNL to accurately transfer the Fuel Assembly Type Codes into Table C.1.1.

-

Initial Cycle in Core

Assembly ID 1

Range

Number of Assemblies

Fuel Assembly Type Code 2, 3, 4

Assembly Identifier must match the primary assembly identifier in Section C.1.1 of the current or prior data collection, whichever is applicable.

Select the Fuel Assembly Type Code from Appendix E or the drop-down menu.

If the Fuel Assembly Type Code is not listed in Appendix E, use the ‘Other’ code provided for each reactor design and provide assembly details in the comments.

The following reactors have their own unique codes: South Texas Units 1 and 2, Ft. Calhoun, Palisades, and St. Lucie Unit 2. See Appendix E.10

Fuel Assembly Type data for all assemblies discharged from January 1, 2003 – December 31, 2017 was collected in the 2018 GC-859 Survey. Survey respondents that provided the requested Fuel Assembly Type data in the previous survey and already included Fuel Assembly Type data under Schedule C.1.1 for the current survey cycle do not need to repeat reporting this information under Schedule C.1.3.

For discharges that are early in this range, the Initial Cycle in Core may extend back several cycles. For example, if Cycle 10 shutdown in January 2003 and it contained three regions of

fuel with LTAs in Cycle 10, input to Table C.1.3 for the first few cycles may look like the following:

-

Example C.1.3 Fuel Assembly Type Code input

Initial Cycle In Core

Assembly ID Range

Number of Assemblies

Fuel Assembly Type Code

8

K01 – K80

80

C1414WT

9

L01 – L68

68

C1414WT

10

M01 - M12, M17 - M76

72

C1414WT

10

M13 – M16

4

C14_OTH

11

N01 – N80

80

C1414WT

Fuel Assembly Type Codes for fuel discharged from January 1, 2018 - December 31, 2022 may also be entered in Schedule C.1.3 if not already entered in Schedule C.1.1.

COMMENTS

Provide any comments you have concerning Fuel Assembly Type Code (Section C.1.3) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Report all shipments of fuel assemblies from this site to another storage site (pool or dry storage) since December 31, 2017. Use the storage site identifiers from Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes.”

-

Assembly Identifier

Original Storage Site Identifier

Current Storage Site Identifier

COMMENTS

Provide any comments you have concerning Shipments/Transfers of Discharged Fuel (Section C.1.4) in the comment section below. The comments may include a description of whether the shipment related to an entire fuel assembly or a rod or other part thereof. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

DOE paused collection of this data starting with the survey covering the July 1, 2013 – December 31, 2017 period.

Report in this section, data on the following. Check all that apply.

Single Assembly Canisters (Complete Schedule C.3.1)

Uncanistered Fuel Rods/Pieces (Complete Schedule C.3.2)

Consolidated/Reconstituted/Reconstructed Assemblies; Dimensionally or Other than LWR Non-Standard Assemblies; & Failed Fuel (Complete Schedule

C.3.3)

A canister is defined as any single assembly canister designed to confine contents that may be delivered to a DOE facility. Within this schedule, canistered material may include damaged assemblies, reconstituted assemblies, fuel rods that have been removed from an assembly, and miscellaneous fuel. Empty canisters should not be reported.

Does your facility have single assembly canisters?

Yes. Complete the remainder of Schedule C.3.1

No. Skip to Schedule C.3.2

For all single assembly canisters, provide a detailed description.

Canister Identifier |

Canister Shape |

Canister Dimensions (to the nearest 0.1 inch) |

Loaded Weight (to nearest lb.) |

Storage Identifier1 |

|||

C |

R |

Length |

Diameter/ Width |

Depth |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C = cylindrical R = rectangular

1See Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes.”

For each canister identified in Schedule C.3.1.1, provide a qualitative description of the contents and identify the method used to close the canister. Also indicate whether the canister may be handled as a standard fuel assembly.

Canister Identifier |

Description of Contents (check all that apply) 1 |

Canister Closure |

Is Canister Handled As A Standard Fuel Assembly? |

|||

B |

W |

NS |

Yes |

No |

||

|

Assembly with failed fuel Reconstituted/reconstructed fuel assembly Fuel rods Fuel debris (rod pieces, fuel pellets, etc.). |

|

|

|

|

|

|

Assembly with failed fuel Reconstituted/reconstructed fuel assembly Fuel rods Fuel debris (rod pieces, fuel pellets, etc.). |

|

|

|

|

|

|

Assembly with failed fuel Reconstituted/reconstructed fuel assembly Fuel rods Fuel debris (rod pieces, fuel pellets, etc.). |

|

|

|

|

|

B = bolted W = welded NS = not sealed

1. Failed Fuel as defined in the Standard Contract and Appendix D – Glossary of Terms

For each canister identified in Schedule C.3.1.1, provide a detailed description of the contents.

Canister Identifier |

Source Assembly Identifier1 |

Number of Fuel Rod Equivalents from Assembly |

Initial Heavy Metal Content2 |

Discharge Burnup3 (MWDt/MTU) |

Initial kgU |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 Source Assembly Identifier must match the primary assembly identifier in Section C.1.1 of the current or prior data collection, whichever is applicable.

2 The Initial Heavy Metal Content is calculated as the weight of only the number of fuel rod equivalents from assembly.

3 Discharge Burnup of Source Assembly Identifier.

COMMENTS

Provide any comments you have concerning Special Fuel Form – Canisters (Section C.3.1.1, C.3.1.2 and C.3.1.3) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Does your facility have uncanistered fuel? Include all materials that were not listed in Schedule C.3.1 (i.e., materials stored in baskets, materials to be repackaged, etc.).

Yes. Complete the remainder of Schedule C.3.2

No. Skip to Schedule C.3.3

For all uncanistered fuel rods and fuel pieces, provide a detailed description.

Source Assembly Identifier1 |

Number of Uncanistered Fuel Rods or Pieces from Assembly |

Initial Heavy Metal Content2 |

Discharge Burnup3 (MWDt/MTU) |

Initial kgU |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 Source Assembly Identifier must match the primary assembly identifier in Section C.1.1 of the current or prior data collection, whichever is applicable.

2 The Initial Heavy Metal Content is calculated as the weight of only the number of fuel rod equivalents from assembly.

3 Discharge Burnup of Source Assembly Identifier.

COMMENTS

Provide any comments you have concerning Special Fuel Form – Uncanistered Fuel Rods/Pieces (Section C.3.2) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

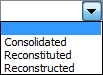

Does your facility have consolidated/reconstituted/reconstructed assemblies? Include assemblies that have been modified by removing or replacing fuel rods.

Yes. Complete the remainder of Schedule C.3.3.1

No. Skip to Schedule C.3.3.2

For each consolidated/reconstituted/reconstructed assembly provide a detailed description.

-

Type1

Current Location (Assembly Identifier)

Source Assembly Identifier2

Number of Rods from Source Assembly (or other location)

Initial Heavy

Metal Content3

Description of Assembly

Initial kgU

1 Current Location Assembly Identifier and Source Assembly Identifier may only match if Type is Reconstructed.

2 Source Assembly Identifier must match the primary assembly identifier in Section C.1.1 of the current or prior data collection, whichever is applicable. If source assembly is not used (i.e. reconstituted with new rods), input type of rod used. Typical examples are Stainless Steel, Natural U-235, Enriched U-235, Inert Rod, or Water Rod.

3 The Initial Heavy Metal Content is calculated as the weight of only the number of fuel rods from source assembly.

COMMENTS

Provide any comments you have concerning Special Fuel Form – Consolidated/Reconstituted/Reconstructed Assemblies (Section C.3.3.1) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Does your facility have non-standard assemblies as defined in the Standard Contract Appendix E paragraphs B.1 Maximum Nominal Physical Dimensions or B.4 Non-LWR?

Yes. Complete the remainder of Schedule C.3.3.2

No. Skip to Schedule C.3.3.3

For each assembly that is non-standard due to either exceeding the maximum nominal physical dimensions specification set forth in Appendix E of the Standard Contract (also provided below) or being other than light water reactor (LWR) assembly, please provide the assembly identifier and a description of why the assembly is non-standard.

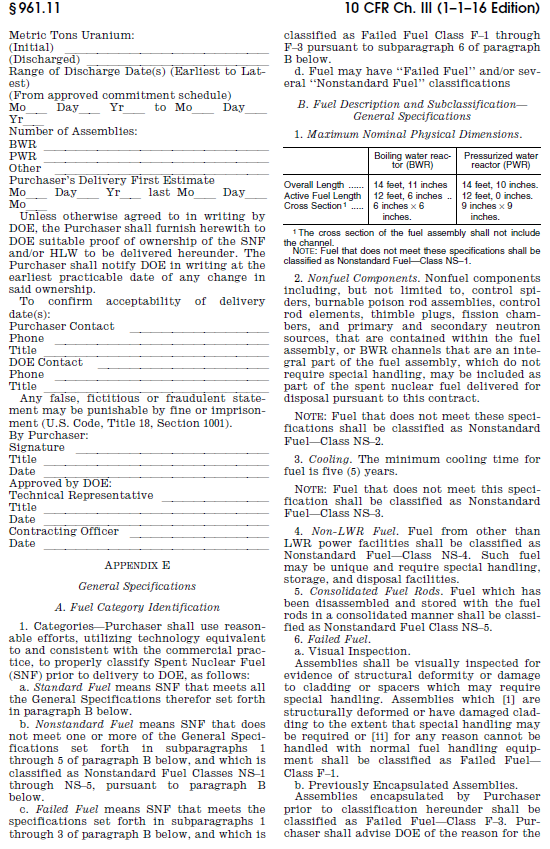

Maximum Nominal Physical Dimensions

|

Reactor (BWR) |

Reactor (PWR) |

Overall Length |

14 feet, 11 inches |

14 feet, 10 inches |

Active Fuel Length |

12 feet, 6 inches |

12 feet, 0 inches |

Cross Section* |

6 inches x 6 inches |

9 inches x 9 inches |

*The Cross Section of the fuel assembly shall not include the channel.

Assembly Identifier1 |

Description of Non-Standard Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1

Assembly

Identifier

must

match

the

primary

assembly

identifier

in

Section

C.1.1

of

the

current

or

prior

data

collection,

whichever

is applicable.

1

Assembly

Identifier

must

match

the

primary

assembly

identifier

in

Section

C.1.1

of

the

current

or

prior

data

collection,

whichever

is applicable.

All fuel from this reactor is considered non-standard.

COMMENTS

Provide any comments you have concerning Special Fuel Form – Dimensionally or Other Than LWR Non- standard Assemblies (Section C.3.3.2) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Does your facility have failed fuel?

Failed Fuel Classes F-1 and F-3 are defined in the Standard Contract Appendix E. For Class F- 2 Radioactive “Leakage” use the definition consistent with NRC NUREG-1617, Standard Review Plan for Transportation Packages for Spent Nuclear Fuel: “Damaged Spent Nuclear Fuel: spent nuclear fuel with known or suspected cladding defects greater than a hairline crack or a pinhole leak.”

Note: A copy of the Standard Contract is provided in Appendix B.

Yes. Complete the remainder of Schedule C.3.3.3

No. Skip to Schedule C.4

For each assembly with failed fuel that is currently stored canistered or uncanistered in the pool, provide the assembly identifier and a description of why the assembly is classified as Failed Fuel.

Assembly Identifier1 |

Failed Fuel Class2 |

Description of Failure |

|

|

|

|

|

|

|

|

|

|

|

|

1 Assembly Identifier must match the primary assembly identifier in Section C.1.1 of the current or prior data collection, whichever is applicable.

2 Chose from pulldown menu: F-1: Visual Failure or Damage; F-2: Radioactive “Leakage”; F-3: Encapsulated

COMMENTS

Provide any comments you have concerning Special Fuel Form – Failed Assemblies (Section C.3.3.3) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Has your utility entered into a contract for reprocessing any discharged fuel which will result in high level waste expected to be disposed of by the Federal Government?

Yes.

No.

Domestic

International

Both Domestic and International

What quantity of discharged fuel will be reprocessed?

(Metric Tons)

|

|

|

|

|

COMMENTS

Provide any comments you have concerning Potential High-Level Waste (Section C.4) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

SCHEDULE D: STORAGE FACILITY DATA

Provide

a storage

facility point

of contact

for verification

of information

provided on

this form. If

contact information is the same as in Schedule A or B, insert X in

the block. A B

Provide

a storage

facility point

of contact

for verification

of information

provided on

this form. If

contact information is the same as in Schedule A or B, insert X in

the block. A B

Name:

Title:

Mailing Address:

City: State: Zip Code:

Telephone Number:

Email:

COMMENTS

Provide any comments you have concerning Storage Facility Point of Contact (Sections D.1) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Complete a Schedule D.2 for each pool storage site.

(See Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes.”)

|

Number of Assemblies |

|

BWR |

PWR |

|

Current NRC Licensed Storage Capacity |

|

|

Current Installed Storage Capacity |

|

|

Current NRC Licensed Storage Capacity -- report in number of assemblies. If the site is licensed for different types of fuel (PWR, BWR), note each in the appropriate column. Note any change from previous reporting period in the comments.

Current Installed Storage Capacity -- report in number of assemblies. If the site is licensed for different types of fuel (PWR, BWR), note each in the appropriate column. Do not deduct inventory from current capacity.

Note in the comments if some of the storage capacity is unusable due to mechanical/physical limitations.

Storage Inventory -- Provide the number of assemblies stored at the storage site. Also enter the number of assemblies discharged from each contributing reactor that are stored at the storage site.

Contributing Reactor Name |

Number of Assemblies |

|

|

|

|

|

|

|

|

Total Storage Site Inventory |

|

COMMENTS

Provide any comments you have concerning Storage Facility Information (Pool Storage) (Sections D.2.1, D.2.2 and D.2.3) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

If your company has implemented a dry storage cask storage system at your site, an independent spent fuel storage installation (ISFSI), provide the following information.

(See Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes.”)

Number of multi-assembly canisters/casks in service

For each canister/cask model, provide and/or reference a loading map that clearly indicates identifiers for basket cell locations relative to fixed drain and vent port locations. For systems stored horizontally, map should indicate which direction is “up” when placed in horizontal storage module. Map reference should cite page number and figure number from either the Certificate of Compliance (CoC), a completed plant procedure, or Final Safety Analysis Report (FSAR). Provided maps should be in the form of a pdf file.

-

Unique Canister/Cask

Identifier

Vendor

Model Number

Date Loaded (MM/YYYY)

Number of Assemblies

Stored

Map Reference

Map Filename

Total Number of Assemblies in Dry Storage

Note: If there were any anomalies or deviations from the standard operating procedures, FSAR and/or CoC experienced during the canister or cask drying, backfilling, leak test, or pad transfer processes (e.g., inadvertent stoppage of active cooling, insufficient helium backfill), provide specific details in the comment section.

COMMENTS

Provide any comments you have concerning Storage Facility Information (Dry Storage) (Sections D.3.1, D.3.2) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

For each multi-assembly canister/cask, enter the assembly identifier and position according to the map for each assembly in that canister/cask.

-

Unique Canister/Cask Identifier

Assembly Identifier1

Position According to Map

1 Assembly Identifier must match the primary assembly identifier in Section C.1.1 of the current or prior data collection, whichever is applicable.

COMMENTS

Provide any comments you have concerning Storage Facility Information (Dry Storage) (Section D.3.3) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

SCHEDULE E: NON-FUEL DATA

All materials not listed in Schedule C.3, Special Fuel Forms, should be included here. Non-fuel components may be integral to an assembly (enter data in Schedule C.1.1), canistered (enter data in Schedule E.3), or separate from an assembly and uncanistered in the storage pool (enter data in Schedule E.4).

Does your facility have non-fuel components that may be delivered to a DOE facility?

Yes. Complete the remainder of Schedule E

No. Skip to Schedule F

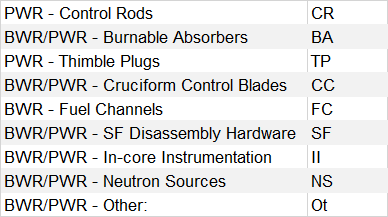

Non-fuel components are defined in the Standard Contract, as including, but not limited to, burnable poison rod assemblies, control rod elements, thimble plugs, fission chambers, and primary and secondary neutron sources, that are contained within the fuel assembly, or BWR channels that are an integral part of the fuel assembly, which do not require special handling and may be included as part of the spent nuclear fuel. Note: Fuel that does not meet these specifications shall be classified as non-standard fuel.

This data is reported in C.1.1 columns 10, 11, and 12. E.2 is no longer used and is kept as a place holder for consistency with prior surveys. If reporting this data in C.1.1 instead of E.2 is a large burden to the respondent, please contact PNNL. For non-fuel components (NFCs) which have been moved during the current reporting period to or from an assembly identified as being discharged in a previous reporting period, NFC-related information for the affected assembly or assemblies can be updated in Schedule C.1.1. Please contact PNNL for any assistance.

A canister is defined as a container designed to confine waste that may be delivered to a DOE facility. Report in this Schedule non-fuel components data for single assembly canisters or containers which are currently stored in a storage pool. Data for single assembly canisters that contain any spent nuclear fuel should also be reported in Schedule C.3, Special Fuel Forms.

Are there canisters or containers of non-fuel components in your pool planned for delivery to a DOE facility?

Yes. Provide the data requested in the table below for each canister

PWR

-

Control

Rods

PWR

- Thimble Plugs BWR

- Cruciform Control Blades BWR - Fuel Channels

BWR/PWR

-

Burnable

Absorbers BWR/PWR

-

SF

Disassembly

Hardware

BWR/PWR - In-core Instrumentation BWR/PWR - Neutron Sources BWR/PWR

–

Other:

Canister Identifier |

Canister Shape |

Canister Dimensions (to nearest 0.1 inch) |

Loaded Weight (lbs)1 |

Type of Non-fuel Component2 |

Number of Individual Items |

Canister Closure |

Is Canister Handled As A Standard Fuel Assembly? 3 |

Storage Location4 |

||||||

C |

R |

Length |

Diameter/ Width |

Depth |

B |

W |

NC |

Yes |

No |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C = cylindrical R = rectangular B = bolted W = welded NC = not closed

1 Loaded Weight is the weight of the Canister including the non-fuel components.

2 For each canister identified in Schedule E.3 in which non-fuel components are stored, list and estimate the number of each applicable type of non-fuel component that is stored in that canister.

3 Indicate whether the canister may be handled as a standard fuel assembly, using the same equipment used to move assemblies.

4 The storage location is from Appendix C, “Reactor and Spent Fuel Storage Site Identification Codes”.

COMMENTS

Provide any comments you have concerning Non-Fuel Data (Non-fuel Components – Canistered) (Section E.3) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Does your facility have uncanistered non-fuel components that are separate from an assembly and currently stored in a storage pool that are planned for delivery to a DOE facility?

Yes. Complete the remainder of Schedule E.4

No. Skip to Schedule F

List

and estimate

the number

of each

applicable type

of uncanistered

non-fuel component

separate from

an assembly and indicate the storage pool location from

Appendix C “Reactor and Spent Fuel Storage Site Identification

Codes”.

List

and estimate

the number

of each

applicable type

of uncanistered

non-fuel component

separate from

an assembly and indicate the storage pool location from

Appendix C “Reactor and Spent Fuel Storage Site Identification

Codes”.

-

Type of Non-fuel Component

Number of Individual Items

Storage Location

PWR - Control Rods

PWR - Thimble Plugs

BWR - Cruciform Control Blades BWR - Fuel Channels BWR/PWR - Burnable Absorbers

BWR/PWR - SF Disassembly Hardware BWR/PWR - In-core Instrumentation BWR/PWR - Neutron Sources BWR/PWR – Other:

COMMENTS

Provide any comments you have concerning Non-Fuel Data (Non-fuel Components – Separate from an Assembly and Uncanistered) (Section E.4) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

SCHEDULE F: GREATER-THAN-CLASS-C WASTE DATA

DOE is requesting information on Greater-Than-Class C waste (GTCC) inventories. GTCC is waste in which the concentrations of radionuclides exceed the limits for Class C low-level radioactive waste established by the Nuclear Regulatory Commission (NRC) in 10 CFR Part 61.55, Tables 1 and 2.

Provide

a GTCC

point of

contact for

verification of

information provided

on this

form. If contact information is the same as in Schedule A or B

insert X in the block.

Provide

a GTCC

point of

contact for

verification of

information provided

on this

form. If contact information is the same as in Schedule A or B

insert X in the block.

A B

Name:

Title:

Mailing Address:

City: State: Zip Code:

Telephone Number:

Email:

COMMENTS

Provide any comments you have concerning Greater-Than-Class-C Waste Data Point of Contact (Section F.1) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Include in this section GTCC waste that is currently packaged and available for disposal as of December 31, 2022.

Activated

metals are removed from the reactor prior to decommissioning

nuclear reactors. Portions of the reactor assembly and other

components near

the nuclear

fuel are

activated by

neutrons during

reactor operations,

producing high

concentrations of

radionuclides. The

major radionuclides in these wastes are typically cobalt-60,

nickel-63, niobium-94, and carbon-14.

Activated

metals are removed from the reactor prior to decommissioning

nuclear reactors. Portions of the reactor assembly and other

components near

the nuclear

fuel are

activated by

neutrons during

reactor operations,

producing high

concentrations of

radionuclides. The

major radionuclides in these wastes are typically cobalt-60,

nickel-63, niobium-94, and carbon-14.

-

Pack aged Volume (ft3)1

Pack age Contents2

Pack aging3

Package Dimensions

Loaded Weight of

Pack age (lbs)

Date Pack aged

Total Pack age Activity4 (MCi)

Radionuclide5

Remotely Handled6

Date of Last Criticality

(MM/YYYY)7

Latest Date of Segmentation (MM/YYYY)8

Type

Number

External Length (in)

External Diameter (in)

External Volume (ft3)

Internal Volume (ft3)

Yes

No

1

1 Packaged Volume (ft 3): Combined volume of the waste and the storage container.

2 Package Contents: Identify the contents of each package.

3 Packaging Type and Number: Provide an entry for each waste stream indicating the type of package (for other, describe what the package is) and the quantity of packages.

4 Total Package Activity (MCi): Report the total activity of the package in million curies associated with the activated metals.

5 Radionuclide: Report the radionuclides that account for > 1% of total activity anticipated in the waste stream.

6 Remotely Handled: If the package has a dose rate of greater than 200 mrem/hr on the surface of the package, indicate if the package must be remotely handled.

7 Date of Last Criticality: The date of last criticality is the date the reactor was last critical from which the metal was derived.

8 Latest Date of Segmentation: For activated metal waste, indicate the date when the waste segmentation was complete.

* Alpha emitting transuranic nuclides with half-life greater than 5 years

COMMENTS

Provide any comments you have concerning GTCC Stored Inventory - Activated Metals (Section F.2.1) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Process and other waste includes GTCC waste that is not activated metals. It consists of contaminated equipment, debris, trash, filters, resins, scrap metal, and decontamination and decommissioning waste.

1

Packaged

Volume

(ft

3):

Combined

volume

of

the

waste

and

the

storage

container.

1

Packaged

Volume

(ft

3):

Combined

volume

of

the

waste

and

the

storage

container.

2 Package Contents: Identify the contents of each package (e.g., resins, filters, etc.).

3 Packaging Type and Number: Provide an entry for each waste stream indicating the type of package (for other, describe what the package is) and the quantity of packages.

4 Total Package Activity (MCi): Report the total activity of the package in million curies associated with the process waste.

5 Radionuclide: Report the radionuclides that account for > 1% of total activity anticipated in the waste stream.

6 Remotely Handled: If the package has a dose rate of greater than 200 mrem/hr on the surface of the package, indicate if the package must be remotely handled.

7 Date Contents Were Removed From Service: For multiple dates, use the latest date.

8 RCRA Listed Hazardous Waste Constituents or Characteristics: If mixed waste, list any Resource Conservation and Recovery Act (RCRA) hazardous waste constituents or characteristics.

* Alpha emitting transuranic nuclides with half-life greater than 5 years

COMMENTS

Provide any comments you have concerning GTCC Stored Inventory - Process Waste/Other Waste (Section F.2.2) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

Schedule and Item Number |

Comment |

|

|

|

|

|

|

Include GTCC waste not packaged and waste projected to be generated from licensed activities from 2023 through reactor decommissioning. Include all waste not in F.2.1.

-

Years Packaged

Description of Waste1

Estimated Unpackaged Volume2 (ft3)

Estimated Packaged Volume3 [If known]

(ft3)

2023-2030

2031-2040

2041-2050

2051-2060

2061-2070

1 Description of Waste: Identify the specific content of the waste.

2 Estimated Unpackaged Volume (ft3): Volume of only the waste without any storage container.

3 Estimated Packaged Volume (ft3): Volume of the waste including any storage container.

COMMENTS

Provide any comments you have concerning GTCC Projected Inventory – Activated Metals (Section F.3.1) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

-

Schedule and Item Number

Comment

Include process and other GTCC waste not packaged and waste projected to be generated from licensed activities from 2023 through reactor decommissioning. Include all waste not in F.2.2.

-

Years Packaged

Description of Waste1

Estimated Unpackaged Volume2 (ft3)

Estimated Packaged Volume3 [If known]

(ft3)

RCRA Listed Hazardous Waste Constituents or Characteristics4

2023-2030

2031-2040

2041-2050

2051-2060

2061-2070

1 Description of Waste: Identify the specific content of the waste. (e.g., resins, filters, etc.)

2 Estimated Unpackaged Volume (ft3): Volume of only the waste without any storage container.

3 Estimated Packaged Volume (ft3): Volume of the waste including any storage container.

4 RCRA Listed Hazardous Waste Constituents or Characteristics: If mixed waste, list any Resource Conservation and Recovery Act (RCRA) hazardous waste constituents or characteristics.

COMMENTS

Provide any comments you have concerning GTCC Projected Inventory – Process Waste/Other Waste (Section F.3.2) in the comment section below. Label your comments by the Schedule and Item Number to which they refer.

-

Schedule and Item Number

Comment

APPENDIX A – INSTRUCTIONS FOR COMPLETING NUCLEAR FUEL DATA FORM GC-859

Purpose and Use of Data

The Form GC-859 Nuclear Fuel Data survey collects data that the DOE uses for assessing storage and disposal requirements for spent fuel, high level waste, and GTCC waste.

Who Should Submit

This form should be submitted by all owners and custodians of spent nuclear fuel and/or high-level radioactive waste.

When To Submit

This form shall be submitted by September 30, 2023 following receipt of the form. Unless otherwise indicated, data on the form should reflect the spent fuel discharged from January 1, 2018 - December 31, 2022.

What To Submit

DOE will provide respondents with an online platform to facilitate their responses. The Form GC-859 data collection system is automated. Respondents will also be provided with electronic files to aid in the current submittal and operating instructions for the software.

To the greatest extent practicable, respondents will provide data either in the data collection system or as any commonly readable, present-day electronic spreadsheet file type. If the respondent is unable to provide the data in commonly readable present-day electronic spreadsheet format, the respondent will be required to re- verify any data which is manually input by DOE.

Sign Schedule A and return it with your data to the address in Section 5, below.

Where To Submit

Please use the following website to submit your data: https://gc859.pnnl.gov. Alternatively, you may request a copy of the submission software from the PNNL GC-859 Survey Team contact.

Also include a signed copy (i.e., scanned to PDF file) of Schedule A along with your submittal. A signed copy of Schedule A is not required if submitting through the website.

You will receive a notice from the website confirming receipt of the files. If you have not received a confirmation notice within three business days, contact the PNNL GC-859 Survey Team at the telephone number or email provided on the cover sheet of this form.

Legal Authority and Sanctions Statement

Data on this mandatory form are collected under authority of the Federal Energy Administration Act of 1974 (15 USC Schedule 761 et seq.), and the Nuclear Waste Policy Act of 1982 (42 USC 10101 et seq.). Data being collected on this form are not considered to be confidential.

Instructions for filing the individual Schedules of the Form GC-859 survey are included within the schedules. Operating instructions for the software are provided with the Form GC-859 data collection system.

APPENDIX B – GENERAL SPECIFICATION FROM APPENDIX E OF THE STANDARD CONTRACT (10 CFR 961.11)

61 of 86

APPENDIX C – REACTOR AND SPENT FUEL STORAGE SITE IDENTIFICATION CODES

Storage

Location

Reactor

ID

Storage

Site

ID

Note

Aerotest

8001

8001

Arkansas

Nuclear

One

-

Unit

1

0401

0401

Arkansas

Nuclear

One

-

Unit

2

0402

0402

Arkansas

Nuclear

One

(ISFSI)

-

0401D

DC

Beaver

Valley

-

Unit

1

1601

1601

Beaver

Valley

-

Unit

2

1602

1602

Beaver

Valley

(ISFSI)

-

1601D

DC

Big

Rock

Point

1201

1201

Big

Rock

Point

(ISFSI)

-

1201D

DC

Braidwood

-

Unit

1

1001

1001

CP

Braidwood

-

Unit

2

1002

1001

CP

Braidwood

(ISFSI)

-

1001D

DC

Browns

Ferry

-

Unit

1

4803

4803

TC

Browns

Ferry

-

Unit

2

4804

4803

TC

Browns

Ferry

-

Unit

3

4805

4805

Browns

Ferry

(ISFSI)

-

4803D

DC

Brunswick

-

Unit

1

0701

0701

Brunswick

-

Unit

2

0702

0702

Brunswick

(ISFSI)

-

0701D

DC

BWXT

Services

(Lynchburg)

7101

7101

Byron

-

Unit

1

1003

1003

CP

Byron

-

Unit

2

1004

1003

CP

Byron

(ISFSI)

-

1003D

DC

Callaway

5101

5101

Callaway

(ISFSI)

-

5101D

DC

Calvert

Cliffs

-

Unit

1

0501

0501

TC

Calvert

Cliffs

-

Unit

2

0502

0501

TC

Calvert

Cliffs

(ISFSI)

-

0501D

DC

Catawba

-

Unit

1

1501

1501

Catawba

-

Unit

2

1502

1502

Catawba

(ISFSI)

-

1501D

DC

Clinton

2301

2301

Clinton

(ISFSI)

-

2301D

DC

Columbia

5302

5302

Columbia

(ISFSI)

-

5302D

DC

Comanche

Peak

-

Unit

1

4901

4901

TC

Comanche

Peak

-

Unit

2

4902

4901

TC

Comanche

Peak

(ISFSI)

-

4901D

DC

Cook

-

Unit

1

5801

5801

CP

Cook

-

Unit

2

5802

5801

CP

Cook

(ISFSI)

-

5801D

DC

Cooper

Station

3001

3001

Cooper

Station

(ISFSI)

-

3001D

DC

Crystal

River

3

1701

1701

Crystal

River

3

(ISFSI)

-

1701D

DC

Davis-Besse

5001

5001

Davis-Besse

(ISFSI)

-

5001D

DC

Diablo

Canyon

-

Unit

1

3501

3501

Diablo

Canyon

-

Unit

2

3502

3502

Diablo

Canyon

(ISFSI)

-

3501D

DC

Dow

8103

8103

Dresden

-

Unit

1

1005

1005

Dresden

-

Unit

2

1006

1006

Dresden

-

Unit

3

1007

1007

Dresden

(ISFSI)

-

1005D

DC

Duane

Arnold

2401

2401

Duane

Arnold

(ISFSI)

-

2401D

DC

Enrico

Fermi

2

1402

1402

Enrico

Fermi

2

(ISFSI)

-

1402D

DC

Farley

-

Unit

1

0101

0101

Storage

Location

Reactor

ID

Storage

Site

ID

Note

Farley

-

Unit

2

0102

0102

Farley

(ISFSI)

-

0101D

DC

Fitzpatrick

3901

3901

Fitzpatrick

(ISFSI)

-

3901D

DC

Fort

Calhoun

3401

3401

Fort

Calhoun

(ISFSI)

-

3401D

DC

Fort

St.

Vrain

4101

4101

Fort

St.

Vrain

(ISFSI)

-

4101D

DC

General

Atomics

8102

8102

GE-Hitachi

(Morris)

-

6601

GE-Hitachi

(Vallecitos)

-

6201

Ginna

4401

4401

Ginna

(ISFSI)

-

4401D

DC

Grand

Gulf

2901

2901

Grand

Gulf

(ISFSI)

-

2901D

DC

H.

B.

Robinson

0705

0705

H.

B.

Robinson

(ISFSI)

-

0705D

DC

Haddam

Neck

5701

5701

Haddam

Neck

(ISFSI)

-

5701D

DC

Harris

0703

0703

Harris

(ISFSI)

-

0703D

DC

Hatch

-

Unit

1

2001

2001

TC

Hatch

-

Unit

2

2002

2001

TC

Hatch

(ISFSI)

-

2001D

DC

Hope

Creek

4201

4201

Hope

Creek/Salem

(ISFSI)

-

4201D

DC

Humboldt

Bay

3503

3503

Humboldt

Bay

(ISFSI)

-

3503D

DC

Idaho

National

Laboratory

-

7002

Indian

Point

-

Unit

1

1101

1101

Indian

Point

-

Unit

2

1102

1102

TC

Indian

Point

-

Unit

3

3902

1102

TC

Indian

Point

(ISFSI)

-

1101D

DC

Kewaunee

5501

5501

Kewaunee

(ISFSI)

-

5501D

DC

Lacrosse

1301

1301

Lacrosse

(ISFSI)

-

1301D

DC

LaSalle

County

-

Unit

1

1008

1008

TC

LaSalle

County

-

Unit

2

1009

1008

TC

LaSalle

County

(ISFSI)

-

1008D

DC

Limerick

-

Unit

1

3701

3701

TC

Limerick

-

Unit

2

3702

3701

TC

Limerick

(ISFSI)

-

3701D

DC

Maine

Yankee

2801

2801

Maine

Yankee

(ISFSI)

-

2801D

DC

McGuire

-

Unit

1

1504

1504

McGuire

-

Unit

2

1505

1505

McGuire

(ISFSI)

-

1504D

DC

Millstone

-

Unit

1

3201

3201

Millstone

-

Unit

2

3202

3202

Millstone

-

Unit

3

3203

3203

Millstone

(ISFSI)

-

3201D

DC

Monticello

3301

3301

Monticello

(ISFSI)

-

3301D

DC

Nine

Mile

Point

-

Unit

1

3101

3101

Nine

Mile

Point

-

Unit

2

3102

3102

Nine

Mile

Point

(ISFSI)

-

3101D

DC

North

Anna

-

Unit

1

5201

5201

CP

North

Anna

-

Unit

2

5202

5201

CP

North

Anna

(ISFSI)

-

5201D

DC

Storage Location |

Reactor ID |

Storage Site ID |

Note |

Oconee - Unit 1 |

1506 |

1506 |

CP |

Oconee - Unit 2 |

1507 |

1506 |

CP |

Oconee - Unit 3 |

1508 |

1508 |

|

Oconee (ISFSI) |

- |

1506D |

DC |

Oyster Creek |

1903 |

1903 |

|

Oyster Creek (ISFSI) |

- |

1903D |

DC |

Pacific Northwest National Laboratory |

- |

8401 |

|

Palisades |

1204 |

1204 |

|

Palisades (ISFSI) |

- |

1204D |

DC |

Palo Verde - Unit 1 |

0301 |

0301 |

|

Palo Verde - Unit 2 |

0302 |

0302 |

|

Palo Verde - Unit 3 |

0303 |

0303 |

|

Palo Verde (ISFSI) |

- |

0301D |

DC |

Peach Bottom - Unit 2 |

3704 |

3704 |

|

Peach Bottom - Unit 3 |

3705 |

3705 |

|

Peach Bottom (ISFSI) |

- |

3704D |

DC |

Perry - Unit 1 |

0901 |

0901 |

|

Perry (ISFSI) |

- |

0901D |

DC |

Pilgrim - Unit 1 |

0601 |

0601 |

|

Pilgrim (ISFSI) |

- |

0601D |

DC |

Point Beach - Unit 1 |

5401 |

5401 |

CP |

Point Beach - Unit 2 |

5402 |

5401 |

CP |

Point Beach (ISFSI) |

- |

5401D |

DC |

Prairie Island - Unit 1 |

3302 |

3302 |

CP |

Prairie Island - Unit 2 |

3303 |

3302 |

CP |

Prairie Island (ISFSI) |

- |

3302D |

DC |

Quad Cities - Unit 1 |

1010 |

1010 |

TC |

Quad Cities - Unit 2 |

1011 |

1010 |

TC |

Quad Cities (ISFSI) |

- |

1010D |

DC |

Rancho Seco |

4501 |

4501 |

|

Rancho Seco (ISFSI) |

- |

4501D |

DC |

River Bend |

2101 |

2101 |

|

River Bend (ISFSI) |

- |

2101D |

DC |

Salem - Unit 1 |

4202 |

4202 |

|

Salem - Unit 2 |

4203 |

4203 |

|

Salem/Hope Creek (ISFSI) |

- |

4201D |

DC |

San Onofre - Unit 1 |

4701 |

4701 |

|

San Onofre - Unit 2 |

4702 |

4702 |

|

San Onofre - Unit 3 |

4703 |

4703 |

|

San Onofre (ISFSI) |

- |

4701D |

DC |

Savannah River Site |

- |

7001 |

|

Seabrook |

5901 |

5901 |

|

Seabrook (ISFSI) |

- |

5901D |

DC |

Sequoyah - Unit 1 |

4808 |

4808 |

CP |

Sequoyah - Unit 2 |

4809 |

4808 |

CP |

Sequoyah (ISFSI) |

- |

4808D |

|

Shoreham |

2601 |

2601 |

|

Storage Location |

Reactor ID |

Storage Site ID |

Note |

South Texas One - Unit 1 |

2201 |

2201 |

|

South Texas One - Unit 2 |

2202 |

2202 |

|

South Texas One (ISFSI) |

- |

2201D |

DC |

St Lucie - Unit 1 |

1801 |

1801 |

|

St Lucie - Unit 2 |

1802 |

1802 |

|

St Lucie (ISFSI) |

- |

1801D |

DC |

Summer |

4601 |

4601 |

|

Summer (ISFSI) |

- |

4601D |

DC |

Surry - Unit 1 |

5203 |

5203 |

CP |

Surry - Unit 2 |

5204 |

5203 |

CP |

Surry (ISFSI) |

- |

5203D |

DC |

Susquehanna - Unit 1 |

3601 |

3601 |

TC |

Susquehanna - Unit 2 |

3602 |

3601 |

TC |

Susquehanna (ISFSI) |

- |

3601D |

DC |

Three Mile Island - Unit 1 |

1901 |

1901 |

|

Trojan |

3801 |

3801 |

|

Trojan (ISFSI) |

- |

3801D |

DC |

Turkey Point - Unit 3 |

1803 |

1803 |

|

Turkey Point - Unit 4 |

1804 |

1804 |

|

Turkey Point (ISFSI) |

- |

1803D |

DC |

Vermont Yankee |

6001 |

6001 |

|

Vermont Yankee (ISFSI) |

- |

6001D |

DC |

Vogtle - Unit 1 |

2003 |

2003 |

TC |

Vogtle - Unit 2 |

2004 |

2003 |

TC |

Vogtle (ISFSI) |

- |

2003D |

DC |

Washington Hanford |

- |

7007 |

|

Waterford 3 |

2701 |

2701 |

|

Waterford 3 (ISFSI) |

- |

2701D |

DC |

Watts Bar - Unit 1 |

4810 |

4810 |

CP |

Watts Bar - Unit 2 |

4811 |

4810 |

CP |

Watts Bar (ISFSI) |

- |

4810D |

DC |

Wolf Creek |

2501 |

2501 |

|

Wolf Creek (ISFSI) |

- |

2501D |

DC |

Yankee Rowe |

5601 |

5601 |

|

Yankee Rowe (ISFSI) |

- |

5601D |

DC |

Zion - Unit 1 |

1012 |

1012 |

CP |

Zion - Unit 2 |

1013 |

1012 |

CP |

Zion (ISFSI) |

- |

1012D |

DC |

TC: Transfer Canal |

|

||

CP: Common Pool Serving Two or More Reactors |

|

||

DC: Dry Storage Site |

|

||

ISFSI: Independent Spent Fuel Storage Installation |

|

||

APPENDIX D – GLOSSARY OF TERMS

Activated Metals: Activated metals result from decommissioning nuclear reactors. Portions of the reactor assembly and other components near the nuclear fuel are activated by neutrons during reactor operations, producing high concentrations of radionuclides. The major radionuclides in these wastes are typically cobalt-60, nickel-63, niobium-94, and carbon-14.

ANSI Assembly Identifier: The serial numbering scheme adopted by the American National Standards Institute (ANSI) to ensure uniqueness of an assembly serial number.

Assembly Identifier: A unique string of alphanumeric characters which identifies an assembly, bundle, or canister for a specific reactor in which it has been irradiated. This identifier should be consistent with other submissions to the DOE/NRC, i.e., previous Form RW-859 and DOE/NRC Form 741.

Average Assembly Weight: Average initial loading weight in kilograms (kg) of heavy metal of fresh fuel assemblies in a batch before they are initially inserted into the reactor core.

Average Discharge Burnup: The average amount of energy produced by each assembly in a batch of spent fuel assemblies discharged from a nuclear reactor, reported in thousand megawatt days thermal per metric ton of uranium (MWDt/MTU).

Average Initial Enrichment: Average initial enrichment for a fresh fuel assembly as specified and ordered in fuel cycle planning. This average should include axial blankets, and axially and radially zoned enrichments.

Basket: An open container into which fuel and/or non-fuel components including rods, sections of rods, fuel pellets, garbage, debris, etc., are placed. Baskets are usually defined as rodlet or garbage and debris containers with dimensions less than that of a fuel assembly.

Batch: A batch (or group) is a logical grouping of assemblies with similar characteristics. All assemblies in a batch have the same initial average enrichment, the same cycle/reactor history, the same current location, the same burnup, the same owner, and the same assembly design characteristics.

Boiling Water Reactor (BWR): A light water reactor in which water, used as both coolant and moderator, is allowed to boil in the core. The resulting steam is used directly to drive a turbine.

Burnup: Amount of thermal energy generated per unit mass of fuel, measured in units of megawatt days thermal per initial metric ton of uranium (MWDt/MTU).

Canister: A single assembly canister is defined as any container designed to confine waste that may be delivered to a DOE facility. A canister has dimensions that fit within the envelope defined by the Standard Contract and can be handled similar to an assembly.

Cell: A physical position in a rack in a storage pool or a dry storage module, which is intended to be occupied by an assembly or equivalent (that is, a canister or an assembly skeleton).

Consolidated Fuel: Fuel rods are removed from an assembly and placed into a canister in a grid with spacing closer than that of an assembly.

Core: The place in the reactor in which the nuclear fuel is irradiated and thermal energy is generated.

Core Size: The fixed number of fuel assemblies that can be irradiated at any one time in the reactor core.

Current Installed Capacity: Total number of assembly storage cells in the spent nuclear fuel pool. Both occupied and unoccupied cells are included in the current capacity.

Current Inventory: Number of spent nuclear fuel assemblies stored at a given site or spent nuclear fuel pool, at a given point in time.

Cycle: For the purposes of this form, a cycle is the time period beginning with the startup of a reactor after refueling (or initial fueling) to the time the reactor is considered subcritical. Refueling times should not be included in cycle lengths.

DOE Facility: The term DOE facility means a facility operated by or on behalf of DOE for the purpose of disposing of spent nuclear fuel and/or high-level radioactive waste, or such other facility(ies) to which spent nuclear fuel and/ or high-level radioactive waste may be shipped by DOE prior to its transportation to a disposal facility.

Enrichment: A nuclear fuel cycle process in which the concentration of fissionable uranium is increased above its natural level. Enrichment is the process that changes the isotopic ratio in a material.

Failed Fuel: Failed Fuel Class F-1 Visual Failure or Damage and Class F-3 Encapsulated are defined in the Standard Contract Appendix E. For Class F-2 Radioactive “Leakage” use the definition consistent with NRC NUREG-1617, Standard Review Plan for Transportation Packages for Spent Nuclear Fuel: “Damaged Spent Nuclear Fuel: spent nuclear fuel with known or suspected cladding defects greater than a hairline crack or a pinhole leak”

Fuel Assembly: The basic unit of nuclear fuel. Uranium dioxide (UO2) pellets are encased in cladding to form a fuel rod. Fuel rods are structurally connected to form a fuel assembly.

Fuel Cycle: The length of time a reactor is operated between refueling, typically 18 to 24 months, including the refueling time, measured from the startup of one cycle to the startup of the following cycle.

Greater Than Class C (GTCC) Waste: Greater-Than-Class-C waste (GTCC) is generated by licensees of the NRC. The waste has concentrations of certain radionuclides above the Class C limits as stated in 10 CFR

61.55. Most forms of GTCC waste are generated by routine operations at nuclear power plants. Examples of GTCC waste could include activated metal hardware (e.g., nuclear power reactor control rods), spent fuel disassembly hardware, ion exchange resins, filters and evaporator residues.

High-Level Radioactive Waste (HLW): (A) the highly radioactive material resulting from the reprocessing of spent nuclear fuel, including liquid waste produced directly in reprocessing and any solid material derived from such liquid waste that contains fission products in sufficient concentrations; and (B) other highly radioactive material that the [Nuclear Regulatory] Commission, consistent with existing law, determines by rule requires permanent isolation.

High-Temperature, Gas-Cooled Reactor (HTGR): A reactor that is cooled by helium and moderated by graphite.

Independent

Spent

Fuel

Storage

Installation

(ISFSI): A

dry storage

complex designed

and constructed

for the interim storage of spent nuclear fuel; solid,

reactor-related, greater than Class C waste; and other associated

radioactive materials. A spent fuel storage facility may be

considered independent, even if it is located on the site of another

NRC-licensed facility.

Independent

Spent

Fuel

Storage

Installation

(ISFSI): A

dry storage

complex designed

and constructed

for the interim storage of spent nuclear fuel; solid,

reactor-related, greater than Class C waste; and other associated

radioactive materials. A spent fuel storage facility may be

considered independent, even if it is located on the site of another

NRC-licensed facility.

Initial Enrichment: The isotopic percentage of uranium-235 or plutonium, by weight, that is present in nuclear fuel.

Initial Loading Weight: Average weight in kilograms (kg) of heavy metal in a fresh fuel assembly before it is inserted into the reactor core.

Lattice Size: Lattice is the arrangement or array of fuel rods in a nuclear fuel assembly.

Light Water Reactor (LWR): A nuclear reactor that uses water as the primary coolant and moderator, with slightly enriched uranium as fuel. There are two types of commercial light water reactors: the boiling water reactor (BWR) and the pressurized water reactor (PWR).

Multi-Assembly Canister/Cask: A container capable of holding multiple assemblies that is designed and licensed for storage purposes.

Non-fuel Components (NFC): As defined in the Standard Contract Appendix E Section B.2.

Non-fuel Component Identifier: A string of alphanumeric characters which identifies a non-fuel component.

Non-standard Fuel: As defined in the Standard Contract Appendix E Section A.1.b.

NRC Licensed Site Capacity: Maximum number of spent nuclear fuel assembly and canister slots licensed for use at a given site or spent nuclear fuel pool, as licensed by the Nuclear Regulatory Commission.

Nuclear Fuel: Fissionable materials that are enriched to such a composition that when placed in a nuclear reactor will support a self-sustaining fission chain reaction, producing heat in a controlled manner for process use.

Permanently Discharged Fuel: Spent nuclear fuel for which there are no plans for reinsertion in the reactor core.