EIA-923 Instructions

Electric Power and Renewable Electricity Surveys

EIA-923 Instructions

OMB: 1905-0129

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx Burden: 4.4 Hours

|

PURPOSE |

Form EIA-923 collects information on the operation of electric power plants and combined heat and power (CHP) plants in the United States (see Required Respondents below). Data collected on this form include electric power generation, fuel consumption, fossil fuel stocks, delivered fossil fuel cost, combustion by-products, operational cooling water data, and operational data for NOx, SO2, particulate matter, mercury, and acid gas control equipment. These data are used to monitor the status and trends of the electric power industry and appear in U.S. Energy Information Administration (EIA) publications and public databases. |

REQUIRED RESPON- DENTS |

Form EIA-923 is a mandatory report for all electric power plants and CHP plants that meet the following criteria:

Monthly Respondents: To lessen the reporting burden, a sample of plants is collected on a monthly basis. Monthly respondents report Schedules 1 through 4B, and Schedule 9. Annual Respondents: Plants that are not selected to respond monthly must respond to all applicable schedules annually for the calendar year. Supplemental Respondents: Plants in the monthly sample are required to report Schedules 6 to 8 annually if the criteria for those schedules are applicable. |

RESPONSE DUE |

Monthly respondents are required to file Schedules 1 through 4B and Schedule 9 of this form with EIA by the last day of the month following the reporting period. For example, if reporting for July, survey data are due to EIA on August 31.

Annual and Supplemental respondents are required to file the form approximately 45 days after the online form opens for annual collection.

Please note that EIA will make every effort to open the annual and supplemental surveys on the first business day of January following the reporting year. |

METHODS OF FILING RESPONSE |

Submit your data electronically using EIA’s secure e-file system. This system uses security protocols to protect information against unauthorized access during transmission.

If you have not registered with the e-file Single Sign-On (SSO) system, send an email message requesting assistance to: EIA-923@eia.gov. If you have registered with SSO, log on at: https://signon.eia.gov/ssoserver/login Retain a completed copy of this survey form for your files. Form EIA-923 Fax: 202-287-1938 |

CONTACTS |

For questions about or problems with the online filing system, send an email to the Form EIA-923 mailbox. For questions regarding the data requested on the form, contact: Chris Cassar: Christopher.Cassar@eia.gov |

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx Burden: 4.4 Hours |

GENERAL

INSTRUCTIONS

GENERAL

INSTRUCTIONS

Revisions to Data Previously Reported through the e-file System

Submit revisions to data previously reported as soon as possible after the error or omission is discovered. Do not wait to revise data until the next reporting month’s form is due. Revisions or adjustments to data should be made only to the survey month(s) to which they pertain (i.e., do not adjust the current month to reflect a revision or adjustment to a prior month submission).

Log on to the e-file system, re-key revised data, indicate in Schedule 9 the nature and date of the revision, and resubmit the data. If the e-file form is locked, contact EIA to request the form be opened for revision.

Remember to save and RESUBMIT (click on the SUBMIT button). Resubmitting will allow the validation edits to re-validate the revised data element(s).

Send an email message to EIA-923@eia.gov indicating the following:

the reporting month and year for which data are being revised,

the data that has been revised, and

the date of the revision.

Alternatively, if the e-file system has been closed for the reporting period, please send an email message containing your changes to EIA-923@eia.gov, and indicate ‘Revision’ in subject line. Be sure to include your Plant ID, the specific revision, and the month and year that is being revised.

Revisions to Data Previously Reported by Facsimile or Email Message

If you report via facsimile or email, you may send a corrected copy of the form, but be sure to indicate the four items, discussed above, in Schedule 9.

Correcting Prepopulated Information

For e-file users, much of the information on the form is prepopulated by EIA. Verify the administrative information on Schedule 1, and if changes are needed, send revisions via email to EIA-923@eia.gov.

Validation Edits

For e-file users, data that fail the interactive validation edits will be amassed into an edit log. Upon hitting the “Submit” button, the system will notify you if there are edits in the log. You will be directed to the log and given the opportunity to either revise the data in question or override the edit flag (thus leaving the response values that triggered the error as is). When an edit is overridden, the system will ask for a comment/explanation. Please leave a comment that explains the anomaly, rather than simply stating the data are correct. Each comment is reviewed by EIA and, if the comment does not sufficiently explain the anomaly, EIA will contact you for clarification.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE

1.

IDENTIFICATION

SCHEDULE

1.

IDENTIFICATION

Verify preprinted information. Provide revisions to EIA via email at EIA-923@eia.gov.

1. Plant Name, Plant ID, and State: These data are established on the Form EIA-860. Revisions should be coordinated with the Form EIA-860 staff.

2. Survey Contact: Enter the person primarily responsible for completing the form.

Supervisor of Contact Person for Survey: Enter the supervisor of the primary contact as an alternative person in the event the primary contact becomes unavailable. The Survey Contact and Supervisor cannot be the same person.

Report for (Company and Plant): Enter the name of the operating company and plant. The plant identification number is assigned by EIA. Enter the plant state and county, and month or year for which data are being reported. State codes are two-character U.S. Postal Service abbreviations.

Regulatory Status: Indicate if the plant should be considered either a utility-operated regulated plant (plants where costs are recovered through rate regulation) or unregulated plant (independent power producers and commercial and industrial sector plants).

CHP Checkbox: Indicate whether or not this facility is a combined heat and power plant (CHP). A CHP plant produces both electric power and another form of useful thermal output, such as heat and/or steam for industrial processes, district heating/cooling, steam for purchase or hot water) from a common source.

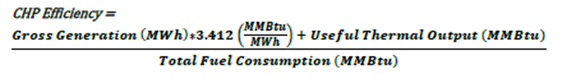

CHP Plant Efficiency: If the CHP checkbox is “YES”, enter the efficiency of the combined heat and power plant. Report the annual average total CHP plant efficiency.

To calculate the total plant efficiency, apply the following formula by dividing the sum of the energy outputs in Btu, including gross generation and useful thermal output, by the sum of the energy inputs (total fuels consumed converted to Btu).

If gross generation is not available, use net generation as an approximation. Total Fuel Consumption

(MMBtu) is found using Schedule 3 fuel quantities multiplied by their average heat content.

SCHEDULE 2. COST AND QUALITY OF FUEL PURCHASES

General Instructions

Required Respondents:

Plants with one or more generating units primarily fueled by coal, natural gas, petroleum coke, distillate fuel oil, or residual fuel oil. Primary Fuel for each generator is reported on the Form EIA-860.

Plants where the total generator nameplate capacity with a Primary Fuel of coal is 50 megawatts or greater; or the total generator nameplate capacity with a Primary Fuel of any combination of natural gas, petroleum coke, distillate fuel oil, or residual fuel oil is 200 megawatts or greater.

Fuel transfer terminals and storage facilities serving generating plants, if the fuel purchases cannot be reported at the plant level.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

Fuel

transfer

terminals

and storage

facilities

guidelines:

Report

fuel

purchases where

quantity, cost,

and

quality data

CANNOT be

reported

by

the

individual

plants

served by

the fuel

terminal.

Report purchases

either

on

the fuel

terminal

report OR

the plant

report,

not both.

Fuel

terminals

must list

the

plants

served

on

Schedule

4B.

Report transfers

out

as

negative

adjustments

to

stocks on

Schedule 4A.

Fuel

transfer

terminals

and storage

facilities

guidelines:

Report

fuel

purchases where

quantity, cost,

and

quality data

CANNOT be

reported

by

the

individual

plants

served by

the fuel

terminal.

Report purchases

either

on

the fuel

terminal

report OR

the plant

report,

not both.

Fuel

terminals

must list

the

plants

served

on

Schedule

4B.

Report transfers

out

as

negative

adjustments

to

stocks on

Schedule 4A.

Report for each fuel purchase: Report for purchases of all coal types, petroleum coke, distillate and residual fuel oils and natural gas by type of fuel, supplier, purchase type, contract expiration date, average cost per MMBtu, fuel quality, and for coal mine origin. Do not aggregate purchases. Report contract and spot market purchases separately, unless specifically instructed below.

Annual Respondents may aggregate some purchases for the entire year provided the contract type and other identifying information, such as mine origin, are identical. For aggregated data, report weighted average costs and quality data.

Coal Purchases: Report data by supplier and mine source. The mine information is reported on Schedule 2, Part C.

Coal or petroleum coke which will be converted to synthesis gas at an Integrated Gasification Combined-Cycle (IGCC) plant: Report the fuel as it is received (i.e., as coal or petroleum coke).

Petroleum Product Purchases: Report data by fuel type, supplier or broker, or refinery and, if applicable, port of entry. Report purchases of residual fuel oil, distillate fuel oil, and petroleum coke.

Do Not Report the Following: Waste oil, kerosene, jet fuel, propane, or other petroleum products.

Natural Gas Purchases: Report natural gas purchases by supplier. Report each contract purchase (not spot purchases) as separate line items -- never aggregate the contracted purchases. Spot market natural gas purchases from various suppliers may be aggregated where it is impractical to list each individually such as when numerous suppliers are used for many relatively small transactions. However, it is preferable to list each supplier separately. If you aggregate your data, report the weighted average cost and quality.

Do Not Report the Following: Other gases such as manufactured gas (coke oven, refinery, or blast furnace gas), propane, landfill gas, or other miscellaneous gaseous fuels, or natural gas injected into storage. Report stored gas when it is received at the plant as an Adjustment on Schedule 4A. Do not report costs associated with storage.

SCHEDULE 2. PART A. CONTRACT INFORMATION, PURCHASES, AND COSTS

Fuel Supplier Name: Supplier names and fuel codes are preprinted from the previous month’s report. Delete unneeded rows. Add supplier/fuel types from the drop-down lists. If the supplier is not on the list, contact EIA to have a new supplier added. If you choose “Name Pending” while waiting for a new supplier to be added, you MUST report the full supplier name in an override comment in response to the edit flag before the data can be submitted.

Purchase Type or Tolling Agreement: Use the following codes:

C – Contract Purchase – Fuel received under a purchase order or contract with a term of one year or longer. Contracts with a shorter term are considered spot purchases (See below.)

NC – New Contract or Renegotiated Contract Purchase – Fuel received under a purchase order or contract with a duration of one year or longer, under which deliveries were first made during the reporting month

S – Spot-Market Purchase – Fuel received under a purchase order or contract with a duration of less than one year

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

T

– Tolling

Agreement –

Fuel received

under

a tolling

agreement (bartering

arrangement of

fuel for

generation)

T

– Tolling

Agreement –

Fuel received

under

a tolling

agreement (bartering

arrangement of

fuel for

generation)

Contract Expiration Date (MMYY): Report for Purchase Types C and NC the month and the year the purchase order or contract expires. For example, report “1119” for a November “2019” expiration date. This column should be left blank for Purchase Types S and T.

Energy Source: Identify fuels using the energy source codes listed in Table 1 for coal, petroleum coke, natural gas, distillate fuel oil, and residual fuel oil. A complete detailed list of energy sources is included in Table 8.

Units of Measure:

Coal and petroleum coke receipts: short tons on an as-received dry basis (if wet, indicate in a comment on Schedule 9)

Petroleum products’ receipts: barrels

Natural gas: thousands of cubic feet (Mcf)

Quantity Purchased: Report the quantity of the fuel purchases for fuel that will ultimately be used for the generation of electricity and, at combined heat and power plants, for useful thermal output (process steam, district heating/cooling, space heating, or steam delivered to other end users).

As far as possible, do not include fuel that will be used in boilers with no connection to an electric power generator or for use in other equipment. If fuel purchases cannot be separated, provide a comment on Schedule 9, Comments.

Report start-up and flame-stabilization fuels.

When fuel is purchased by and received at the plant and a portion is resold, report the quantity minus the amount resold, but report the original average costs and quality of the purchase.

Total Delivered Cost (for coal, petroleum products, petroleum coke, and natural gas): Enter the delivered cost of the fuel in cents per million Btu (MMBtu) to the nearest 0.1 cent. Include all costs incurred in the purchase and delivery of the fuel to the plant. Do not include adjustments associated with prior months’ fuel costs.

Include any penalties/premiums paid or expected to be paid on the fuel delivered during the month in the delivered price for fuel shipped under contract. Make subsequent adjustments only by revising the cost in the month it was reported. Report only the current month fuel costs associated with the current month fuel deliveries. If a portion of a fuel purchase is resold, report the average cents per MMBtu paid for the original purchase. Do not discount the costs by the revenue received for the sale of the fuel.

For coal, include maintenance and depreciation costs of coal delivered in railcars owned by the plant. Do not include unloading costs.

For natural gas, include the following pipeline charges: fuel losses, transportation reservation charges, balancing costs, and distribution system costs outside of the plant. Because these types of fees can skew the cost of the fuel per MMBtu, provide an explanation in an edit log override comment when the price falls outside the range of expected cost, (e.g., “This price includes a reservation fee of x dollars.”).

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

Commodity Cost (for coal, petroleum products, petroleum coke, and natural gas): Report the cost (in cents per million Btu rounded to the nearest 0.1 cent) at the point of first loading (free on board mine or transportation pipeline (FOB)), including taxes and quality-related charges or credits. Do not include loading and unloading charges, dust proofing, freeze conditioning, switching charges, diesel fuel surcharges, pipeline charges, transportation charges, or any other charges relating to the movement of the fuel to the point of use.

In the case of natural gas, the commodity cost is typically the price of the gas FOB the transmission pipeline. In the case of coal, the commodity cost is FOB mine.

For purchases associated with a hedging contract, report the actual fuel supply contract, not the hedge contract. Report the cost net of gains/losses as a result of the contract.

I

I

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE 2. PART B. QUALITY AND TRANSPORTATION OF COAL, PETROLEUM PRODUCTS, AND PETROLEUM COKE

Fuel Supplier Name, Purchase Type, Quantity Purchased, and Energy Source: Data are prepopulated for e-file users based on the data entered on Schedule 2. Part A.

Heat Content: For all fuels, report the actual (not contractual) average Btu content for each fuel purchase in million (MMBtu) per ton, barrel, or thousand cubic feet. Present data values to the nearest

0.001 MMBtu. Refer to Table 1, below, for approximate heat content ranges.

Sulfur Content: For coal, petroleum coke, and residual fuel oil, reports the sulfur content of the fuel in terms of sulfur percentage by weight. Present data values to the nearest 0.01 percent. Refer to Table 1 for approximate sulfur content ranges.

Ash Content: For coal and petroleum coke, enter the ash content of the fuel in terms of ash percentage by weight. Present data values to the nearest 0.01 percent. Refer to Table 1 for approximate ash content ranges.

Moisture Content: For coal only, enter the moisture content of the fuel in terms of moisture percentage by weight. Present data values to the nearest 0.01 percent. Refer to Table 1 for approximate moisture content ranges.

Mercury Content: For coal only, enter the mercury content in parts per million (ppm). Present data values to the nearest 0.001 ppm. If lab tests of the coal receipts do not include the mercury content, enter the amount specified in the contract with the supplier. Refer to Table 1 for approximate mercury content ranges. If the mercury content is not known, mark the checkbox provided for unavailable mercury content.

Chlorine Content: For coal only, enter the chlorine content in parts per million (ppm). Present data values to the nearest 0.001 ppm. If lab tests of the coal do not include the chlorine content, enter the amount specified in the contract with the supplier. Refer to Table 1 for approximate chlorine content ranges. If the chlorine content is not known, mark the checkbox provided for unavailable chlorine content.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

Table

1.

Quality of

Fuel

Table

1.

Quality of

Fuel

-

Fuel Code

Fuel Name

Heat Content (per unit)

Sulfur Content (%)

Ash Content

(%)

Moisture Content (%)

Mercury Content (ppm)

Chlorine Content (ppm)

BIT

Bituminous Coal

19 -29

0.4 – 6.0

4.0 – 30.0

2.0 –16.0

0.020 – 0.500

30 -- 3000

LIG

Lignite Coal

10 - 15

0.4 – 3.0

5.0 – 35.0

30.0 – 60.0

0.020 – 0.500

120 -- 300

SUB

Subbituminous Coal

15 - 20

0.2 – 1.5

3.0 – 15.0

10.0 – 45.0

0.020 – 0.200

40 -- 1200

ANT

Anthracite Coal

22 – 29

0.4 – 6.0

4.0 – 30.0

2.0 – 17.0

0.020 – 0.500

30 -- 3000

RC

Refined Coal

20 – 29

0.2 – 6.0

3.0 – 30.0

2.0 – 30.0

0.020 – 0.500

30 -- 3000

WC

Waste Coal

6.5 – 16

0.3 – 6.0

5.0 – 50.0

2.0 – 60.0

0.020 – 1.200

30 -- 3000

PC

Petroleum Coke

24 – 30

1.0 – 7.0

0.1 – 1.2

RFO

Residual Fuel Oil

5.7 – 6.8

0.2 – 4.5

DFO

Distillate Fuel Oil

5.3 – 6.3

NG

Natural Gas

0.8 – 1.2

Fuel Transportation, Primary Mode: Report the method used to transport the fuel over the longest distance from point of origin to the consumer (the point of origin is the mine for coal deliveries). If the fuel was purchased from a broker or a fuel terminal, and the original mode of transportation is unknown to the purchaser, provide a reasonable assumption for the longest distance from the coal mine (e.g., coal moved from western to eastern states is most likely transported primarily by rail). If the shipment involves only one mode of transportation, that mode is considered the primary mode. If the shipment involves more than one mode of transportation, see the description of secondary mode below.

Secondary Mode: If you used more than one mode of transportation in a single shipment, the secondary mode of transportation is the second longest distance used to transport the fuel to the consumer. If you used more than two transportation modes in a single shipment, report only the primary and secondary modes.

Do Not Report the Following: The transportation modes used entirely within a mine, terminal, or power plant or exclusively on private roads between a mine and rail load-out or barge terminal (e.g., trucks used to move coal from a mine pit to the mine load-out; conveyors at a power plant used to move coal from the plant storage pile to the plant).

Mine-Mouth Coal Plants: Report “Conveyor” as the primary mode, if the conveyor feeding coal to the plant site originates at the mine. Otherwise, report the primary mode (typically truck or rail) used to move the coal to the plant site.

Transportation Mode Codes:

RR – Rail: Shipments of fuel moved to consumers by rail (private or public/commercial). Included is coal hauled to or away from a railroad siding by truck, if the truck did not use public roads.

RV – River: Shipments of fuel moved to consumers via river by barge. Not included are shipments to Great Lakes coal loading docks, tidewater piers, or coastal ports.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

GL

–

Great

Lakes: Shipments of

coal

moved

to

consumers via

the

Great

Lakes. These

shipments are

moved via

the Great

Lakes coal

loading docks,

which are

identified

by

name

and location,

as follows:

GL

–

Great

Lakes: Shipments of

coal

moved

to

consumers via

the

Great

Lakes. These

shipments are

moved via

the Great

Lakes coal

loading docks,

which are

identified

by

name

and location,

as follows:

Conneaut Coal Storage & Transfer, Conneaut, Ohio NS Coal Dock (Ashtabula Coal Dock), Ashtabula, Ohio Sandusky Coal Pier, Sandusky, Ohio

Toledo Docks, Toledo, Ohio

KCBX Terminals Inc., Chicago, Illinois

Superior Midwest Energy Terminal, Superior, Wisconsin

TP – Tidewater Piers and Coastal Ports: Shipments of coal moved to Tidewater Piers and Coastal Ports for further shipments to consumers, via coastal water or ocean. The Tidewater Piers and Coastal Ports are identified by name and location, as follows:

Dominion Terminal Associates, Newport News, Virginia McDuffie Coal Terminal, Mobile, Alabama

IC Railmarine Terminal, Convent, Louisiana International

Marine Terminals, Myrtle Grove, Louisiana Cooper/T. Smith Stevedoring Co. Inc., Darrow, Louisiana Seward Terminal Inc., Seward, Alaska

Los Angeles Export Terminal, Inc., Los Angeles, California Levin-Richmond Terminal Corp., Richmond, California Baltimore Terminal, Baltimore, Maryland

Norfolk Southern Lamberts Point P-6, Norfolk, Virginia Chesapeake Bay Piers, Baltimore, Maryland

Pier IX Terminal Company, Newport News, Virginia Electro-Coal Transport Corp., Davant, Louisiana

WT – Water: Shipments of fuel moved to consumers by other waterways.

TR – Truck: Shipments of fuel moved to consumers by truck. Not included is fuel hauled to or away from a railroad siding by truck, on non-public roads.

TC – Tramway/Conveyor: Shipments of fuel moved to consumers by tramway or conveyor.

SP – Slurry Pipeline: Shipments of coal moved to consumers by slurry pipeline.

PL – Pipeline: Shipments of fuel moved to consumers by pipeline.

OP – On-Site Production: Fuel is produced on site, making fuel shipment unnecessary.

Natural Gas Contract Information – Supply and Delivery Service Contract Type Codes:

F – Firm – Gas transportation service or supply contract provided on a firm basis (i.e., the contract with the gas transportation company anticipates no interruption of gas transportation or supply service). Firm transportation service takes priority over interruptible service.

I – Interruptible – Gas transportation service or supply provided under schedules, or contracts, which anticipate and permit interruption on short notice, such as in peak-load seasons, by reason of the claim of firm service customers and higher priority users.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE

2.

PART C.

COAL MINE

INFORMATION

SCHEDULE

2.

PART C.

COAL MINE

INFORMATION

Fuel Supplier Name, Purchase Type, Quantity Purchased, and Energy Source: Data are prepopulated for e-file users based on the data entered on Schedule 2. Part A.

State or Country of Origin: Choose the two-letter U.S. Postal Service abbreviation or country code from the drop-down list of coal producing states. For imported coal, choose the two-letter country code, shown below:

AS – Australia; CN – Canada; CL – Colombia; IS – Indonesia; PL – Poland;

RS – Russia; VZ – Venezuela; OT – Other (specify the country in Schedule 9).

The state of origin is mandatory. If purchases originate from a broker, barge site or other third party, you must contact the broker, barge site, or other party and find out the state(s) where the coal originated.

If coal purchased under a purchase order or contract originates in more than one state, determine from the supplier the most dominant or probable state(s) of origin for the coal. If the amount of coal from each state/mine is known, allocate the purchase among the states accordingly. If the amount of coal from each state is not known, report the state from which the majority of the coal originated.

Mine Information: Choose the mine from the drop-down list. The list will display only those mines located in the chosen state/country of origin. The displayed information includes the mine operating company, for informational purposes, to aid in identifying the mine of origin. Upon choosing a mine, the MSHA ID, Mine Name, Mine Type and Mine County will automatically be populated. Mine types include U (underground), S (surface), U/S (both an underground and surface mine with most coal extracted underground), S/U (both an underground and surface mine with most coal extracted from the surface), and P (preparation plant – coal is purchased from a preparation plant where it is mechanically cleaned to remove soil and rock, crushed, and then screened/sorted into sizes appropriate for different uses.

If the mine is not on the list, contact EIA if the mine is not on the list, if the mine is unknown, or if the coal came from multiple mines.

SCHEDULE 3. PART A. BOILER AND GENERATOR INFORMATION FOR STEAM-ELECTRIC COMBUSTIBLE-FUELED PLANTS

General Instructions

Required Respondents: Plants with steam turbines (ST) driven by steam from a boiler fueled by combustible fuels must report the fuel consumed in each boiler and the electric power output of each generator.

Do not report for steam turbines where the exclusive energy source is nuclear, geothermal, solar, purchased steam, or waste heat.

Report a value for EACH MONTH. However, plants with less than 10 MW steam-electric nameplate capacity may report annual values for the calendar year.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

Do

not leave

fuel quantity

and net

/gross

generation blank.

Report

zeros

when

no

fuel is

consumed or

electric

power generated.

Do

not leave

fuel quantity

and net

/gross

generation blank.

Report

zeros

when

no

fuel is

consumed or

electric

power generated.

Prime Mover Code: The prime mover code is prepopulated. The only valid code on Schedule 3A is ST. For a complete list of prime mover codes, refer to Table 7.

Boiler ID: Boiler IDs are prepopulated from the latest reported Form EIA-860, Annual Electric Generator Report. If a Boiler ID needs to be added to Schedule 3A, either choose the ID from the drop-down list or contact EIA to have it added to the list. Boiler IDs must match those reported on the Form EIA-860.

3. Boiler Status: Report the status of the boiler during the current reporting period. Enter one of the codes listed in Table 2 below:

Table 2. Boiler Status Codes

-

Code

Boiler Status

OP

Operating (in commercial service or out of service less than 365 days)

OS

Out of service (365 days or longer)

OA

Temporarily out of service (less than 365 days)

RE

Retired (no longer in service and not expected to be returned to service)

SB

Standby (or inactive reserve); i.e., not normally used, but available for service

TS

Construction complete and receiving revenue from the sale of electricity, but not yet in commercial operation

Energy Source: Energy source codes used in the previous reporting period are prepopulated for the current reporting period. Additional codes are listed in Table 8 and can be chosen via the drop-down list. For blended coal products, report an estimated allocation for each coal rank, if this allocation can be determined. For energy source codes OTH, OBS, OBG, OBL and OG, specify the fuel in the text box at the bottom of the data table.

Quantity: For each month, report the amount of fuel consumed in each boiler for electric power generation and, at combined heat and power stations, for useful thermal output. Do not leave blank. Report zero if the fuel was not used in the current reporting period.

Type of Units: Report physical units of fuel consumption as follows: solids in tons; liquids in barrels (one barrel equals 42 U.S. gallons); and gases in thousands of cubic feet (Mcf).

Average Heat Content: Report for all fuels, the average heat content as burned to the nearest 0.001 million Btu (MMBtu) per physical unit. Report the value in the following units: solids in million Btu (MMBtu) per ton; liquids in MMBtu per barrel; and gases in MMBtu per thousand cubic feet (Mcf). Refer to Table 8 for approximate ranges of heat content of specific energy sources.

Report the heat content of the fuel as the gross or “higher heating value” (rather than the net or lower heating value). The higher heating value exceeds the lower heating value by the latent heat of vaporization of the water.

The heating value of fuels that is generally used and reported in a fuel analysis, unless otherwise specified, is the higher heating value. If the fuel heat content cannot be reported “as burned,” obtain data from the fuel supplier on an “as received” basis.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

Sulfur Content (petroleum, petroleum coke, and coal): For each month, enter sulfur content to nearest 0.01 percent by weight. Report sulfur content for the following energy source codes: ANT, BIT, LIG, RC, SUB, WC, PC, RFO, and WO. Refer to Table 1 for approximate sulfur content ranges.

Ash Content (coal and petroleum coke): Report ash content to the nearest 0.1 percent by weight. Report ash content for the following fuel codes: ANT, BIT, LIG, SUB, WC, RC, and PC. Refer to Table 1 for approximate ash content ranges.

Generator ID: Generator IDs are prepopulated on the e-file system form. For a Generator ID that is not prepopulated, choose the ID from the drop-down list of Generator IDs which were reported for your plant on the Form EIA-860. If the Generator ID is not on the selection list, contact EIA to have the ID added to your form. Generator IDs must match those reported on the Form EIA-860.

Generator Status: Enter one of the codes listed in Table 3 below.

Table 3. Generator Status Codes

-

Status Code

Status Code Description

OP

Operating - in service (commercial operation) and producing some electricity. Includes peaking units that are run on an as-needed (intermittent or seasonal) basis.

OA

Temporarily out of service – for less than 365 days

OS

Out of service – was not used for some or all of the reporting period and is NOT expected to be returned to service in the next 365 days

SB

Standby/Backup - available for service but not normally used (has little or no generation during the year) for this reporting period

TS

Construction complete and receiving revenue from the sale of electricity, but not yet in commercial operation

RE

Retired - no longer in service and not expected to be returned to service

Gross Generation: Report the total amount of electric energy produced by generating units and measured at the generating terminal in megawatthours, rounded to the nearest whole number (no decimals).

Net Generation: Enter the net generation (gross generation minus the parasitic station load, i.e., station use) in megawatthours. If the monthly station service load exceeded the monthly gross electrical generation, report negative net generation with a minus sign, not with parentheses.

If your plant is a combined heat and power plant in the Industrial or Commercial Sector, you may choose to leave net generation blank in cases where net generation cannot be determined. Please note that net generation is not defined as electric power sold to the grid (net of direct use), but as gross generation minus station use. If station use is not separable from direct use at combined heat and power plants, report only gross generation, and leave net generation blank. Enter a comment on Schedule 9 if net generation is not reported.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE 3. PART B. FUEL AND GENERATOR INFORMATION FOR SINGLE-CYCLE GAS TURBINES, INTERNAL COMBUSTION ENGINES, HYDROELECTRIC PUMPED STORAGE, COMPRESSED AIR STORAGE AND OTHER ENEGY STORAGE TECHNOLOGIES THAT DELIVER ELECTRIC POWER

Required Respondents: Plants with single-cycle gas turbines (GT), internal combustion engines (IC), fuel cells (FC), pumped-storage hydroelectric plants (PS), compressed air units (CE), other energy storage technologies that deliver electric power such as batteries (BA) and flywheel (FW) electric storage units, or other miscellaneous prime mover types (OT) must report the fuel consumed in the turbines and engines, the electrical energy consumed for storage technologies, and the electric power output for each technology type.

Group all generators of one type together. Do not report for each individual generator. For example, report natural gas consumed and megawatthours produced for all single-cycle gas turbines at the plant as a single value.

Do not report for conventional hydroelectric generators, combined-cycle generators or generators driven by wind, solar, geothermal, and nuclear. These are collected on Schedules 3C and 3D.

Do not leave fuel quantity and net /gross generation blank. Report zeros when no fuel is consumed or electric power generated.

Prime Mover Code: The prime mover codes are prepopulated on the form. If a code needs to be added, choose from the drop-down list. Prime mover descriptions and codes are listed in Table 7.

Energy Source: Energy source codes used in the previous reporting period are prepopulated for the current reporting period. Additional codes are listed in Table 8 and can be chosen via the drop-down list. For energy source codes OTH, OBS, OBG, OBL, and OG, specify the fuel in the text box at the bottom of the data table.

Quantity Consumed: For each prime mover type, report the amount of fuel consumed for electric power generation and, at combined heat and power stations, for useful thermal output. Report the energy consumed for pumping water, compressing air, or other energy storage technologies in megawatthours.

Type of Physical Units: Report fuel consumption in the following units:

Solids – Tons

Liquids – Barrels (one barrel equals 42 U.S. gallons)

Gases – Thousands of cubic feet (Mcf)

Energy Storage – Megawatthours (MWh)

Average Heat Content: Report for all combustible fuels, the average heat content as burned to the nearest 0.001 million Btu (MMBtu) per physical unit. Report the value in the following units: solids in million Btu (MMBtu) per ton; liquids in MMBtu per barrel; and gases in MMBtu per thousand cubic feet (Mcf). Refer to Table 8 for approximate ranges of heat content of specific energy sources. Leave heat content blank if fuel consumed is zero and for pumped storage, compressed air or other energy storage technologies.

Report the heat content of the fuel as the gross or “higher heating value” (rather than the net or lower heating value). The higher heating value exceeds the lower heating value by the latent heat of vaporization of the water. The heating value of fuels that is generally used and reported in a fuel analysis, unless otherwise specified, is the higher heating value.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

If

the

fuel heat

content cannot

be

reported

“as

burned,” obtain

data from

the fuel

supplier on

an

“as

received” basis.

If

the

fuel heat

content cannot

be

reported

“as

burned,” obtain

data from

the fuel

supplier on

an

“as

received” basis.

6. Peaking Unit (Yes/No): Report “Yes” or “No” to indicate if a unit is operated as a peaking unit. Peaking units typically run only during hours of high demand (or peak demand) as opposed to base load units that run continuously except for maintenance or other outages.

7. Gross Generation: Report the total amount of electric energy produced by generating units for each technology (prime mover) type and measured at the generating terminal in megawatthours rounded to the nearest whole number

8. Generation: Report the total amount of net electric energy produced by generating units for each technology (prime mover) type. Net generation is gross generation minus the parasitic station load (i.e., station use). If the monthly station service load exceeded the monthly gross electrical generation, report negative net generation with a minus sign (do not use parentheses).

Combined heat and power plants in the Industrial or Commercial Sector, may leave net generation blank in cases where net generation cannot be determined. Please note that net generation is not defined as electric power sold to the grid (net of direct use), but as gross generation minus station use. If station use is not separable from direct use at combined heat and power plants, report only gross generation, and leave net generation blank.

SCHEDULE 3. PART C. FUEL AND GENERATION INFORMATION FOR COMBINED-CYCLE UNITS

Required Respondents: Plants with combined-cycle units must report the fuel consumed in each combustion turbine and fuel consumed for supplementary firing of the heat recovery steam generator and the electric power output of each generator. Report for single-shaft combustion turbines (CS) combined-cycle combustion turbines (CT), heat recovery steam generators (HRSGs), and steam turbines (CA). Integrated Gasification Combined-Cycle (IGCC) plants also are required to report fuel consumed by the gasifier.

Report a value for EACH MONTH. However, plants with less than 10 MW steam-electric nameplate capacity may report annual values for the calendar year.

Do not leave fuel quantity and net /gross generation blank. Report zeros when no fuel is consumed or electric power generated.

Prime Mover Code: For combustion turbines, the code is CT; for the steam turbine and the HRSG, use CA. For single shaft use CS. The prime mover codes are prepopulated. If the prepopulated code is incorrect, choose the correct code from the drop-down list. For a complete list of prime mover codes, refer to Table 7.

Boiler ID: Boiler IDs are prepopulated on the form. If a Boiler ID needs to be added choose the ID from the drop-down list. If the Boiler ID is not on the list, contact EIA to have it added. Boiler IDs must match those reported on the Form EIA-860.

Boiler Status: Enter one of the codes listed in Table 3 above.

Energy Source: Energy source codes used in the previous reporting period are prepopulated for the current reporting period. Additional codes are listed in Table 8 and can be chosen via the drop-down list. For energy source codes OTH, OBS, OBG, OBL and OG, specify the fuel in the text box at the bottom of

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

the

data table.

Non-supplementary fired

steam

turbines (CA)

should

report Waste

Heat (WH)

as

the energy

source.

the

data table.

Non-supplementary fired

steam

turbines (CA)

should

report Waste

Heat (WH)

as

the energy

source.

Quantity Consumed: Report the quantity of fuel consumed in each combustion turbine (CT). Report supplementary fuel consumed for the steam turbine (duct firing). IGCC units should report the synthesis gas consumed. Non-supplementary fired steam turbines (CA) should leave the quantity blank. IGCC units should report the fuel consumed in the gasifier in the auxiliary table below.

Type of Physical Units: Fuel consumption must be reported in the following units:

Solids – Tons

Liquids – Barrels (one barrel equals 42 U.S. gallons)

Gases – Thousands of cubic feet (Mcf)

Average Heat Content: Report the average heat content as burned to the nearest 0.001 million Btu (MMBtu) per physical unit. Report the value in the following units: solids in million Btu (MMBtu) per ton; liquids in MMBtu per barrel; and gases in MMBtu per thousand cubic feet (Mcf). Refer to Table 8 for approximate ranges of heat content of specific energy sources. Leave heat content blank if fuel consumed is zero.

Report the heat content of the fuel as the gross or “higher heating value” (rather than the net or lower heating value). The higher heating value exceeds the lower heating value by the latent heat of vaporization of the water. The heating value of fuels that is generally used and reported in a fuel analysis, unless otherwise specified, is the higher heating value.

If the fuel heat content cannot be reported “as burned,” obtain data from the fuel supplier on an “as received” basis.

Generator ID: Generator IDs are prepopulated on the form. For a Generator ID that is not prepopulated, choose the ID from the drop-down selection list of Generator IDs that were reported for your plant on the Form EIA-860. If the generator ID is not on the selection list, contact EIA to have the ID added to your form. Generator IDs must match those reported on the Form EIA-860.

Generator Status: Enter one of the codes listed in Table 3 above.

Gross Generation: Report the total amount of electric energy produced by generating units and measured at the generating terminal. For each month, report the megawatthours (MWh) generated, rounded to whole numbers with no decimals.

Net Generation: Report the Net Generation (gross generation minus the parasitic station load, i.e. station use). If the monthly station service load exceeded the monthly gross electrical generation, report negative net generation with a minus sign (do not use parentheses). For each month, enter the net generation amount in MWh.

Combined heat and power plants in the Industrial or Commercial sector may leave net generation blank in cases where net generation cannot be determined. Please note that net generation is not defined as electric power sold to the grid (net of direct use), but as gross generation minus station use. If station use is not separable from direct use at combined heat and power plants, report only gross generation and leave net generation blank.

IGCC Plants – Supplemental Fuel Data for Gasifier Unit: Report the fuel input to the gasifier unit (coal or petroleum coke) along with the average heat, sulfur, and ash contents. See Table 1 in Schedule 2 instructions for approximate heat, sulfur, and ash contents. Report coal and petroleum coke in tons.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE

3. PART

D. GENERATION

FROM NUCLEAR,

NONCOMBUSTIBLE,

AND RENEWABLE

ENERGY SOURCES

SCHEDULE

3. PART

D. GENERATION

FROM NUCLEAR,

NONCOMBUSTIBLE,

AND RENEWABLE

ENERGY SOURCES

Required Respondents: Nuclear plants and plants using renewable energy sources (wind, solar, geothermal, and water in conventional hydroelectric) or other plants where the energy source is solely purchased steam or waste heat. Fuel consumption data are not required for these types of plants. Report generation by energy source for nuclear, wind, solar, geothermal, conventional hydroelectric and miscellaneous sources such as purchased steam or waste heat. Report nuclear data by generating unit. For all other plant types, ignore the Unit Column.

Prime Mover Code: Prime mover codes are prepopulated on the form. Use the codes HY, HA, HB, HK, BT, PV, ST, WT, WS and OT for Schedule 3D. If the prepopulated code is incorrect, choose the correct prime mover code from the drop-down list. Prime mover codes are shown in Table 7.

Energy Source: Energy source codes are prepopulated on the form. Add codes from the drop-down list as needed. A list of all codes is available in Table 8. Valid entries for Schedule 3D are NUC, WAT, WND, GEO, PUR, WH, SUN or OTH.

Unit Code: The nuclear unit code is prepopulated for e-file system forms. Contact EIA if the Unit Code is incorrect. Ignore this field for all other types of plants.

Gross Generation: Enter the total amount of electric energy produced by generating units and measured at the generating terminal. For each month, report the Gross Generation amount in megawatthours (MWh).

Net Generation: Enter the Net Generation (gross generation minus the parasitic station load, i.e. station use). If the monthly station service load exceeded the monthly gross electrical generation, report negative net generation with a minus sign (do not use parentheses). For each month, report the Net Generation amount in MWh.

Combined heat and power plants in the Industrial or Commercial Sector may leave net generation blank in cases where net generation cannot be determined. Please note that net generation is not defined as electric power sold to the grid (net of direct use), but as gross generation minus station use. If station use is not separable from direct use at combined heat and power plants, report only gross generation and leave net generation blank.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE 4. PART A. FOSSIL FUEL STOCKS AT THE END OF THE REPORTING PERIOD FOR COAL, PETROLEUM COKE, DISTILLATE FUEL OIL, AND RESIDUAL FUEL OIL.

Required Respondents: Required Respondents: Plants with one or more generating units primarily fueled by coal (excluding waste coal), natural gas, petroleum coke, distillate fuel oil, or residual fuel oil must report if their total generator nameplate capacity with a primary fuel of coal is 50 or more MW, or if their total generator nameplate capacity with a primary fuel of any combination of natural gas, petroleum coke, distillate fuel oil, or residual fuel oil is 200 MW or greater, (The primary fuel for each generator is reported on the Form EIA-860.) Plants that meet this criteria are required to report their stocks at the end of each reporting period. If Schedule 2, Cost and Quality of Fuel Purchases, is not required, no adjustment to the stocks is required and the fuel balance is not applicable.

Do not report stocks for waste coal, natural gas, biomass, or any petroleum product not mentioned above.

Fuel Terminals: Report stocks held at terminals that will be distributed to the power plants served and reported on this schedule. Report shipments out of the terminal as negative adjustments, using a negative sign and not parentheses. Provide the plants and quantity of fuels moved to each plant on Schedule 4. Part B.

Energy Source: Energy source codes are prepopulated. Energy source codes cannot be deleted from Schedule 4A. If stocks of a fuel type are no longer held at the plant, report a zero (do not leave blank) and contact EIA to remove the energy source code from Schedule 4A.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE

4. PART

B. FOSSIL

FUEL DISTRIBUTION

FROM CENTRAL FUEL

TERMINALS

TO POWER

PLANTS

SCHEDULE

4. PART

B. FOSSIL

FUEL DISTRIBUTION

FROM CENTRAL FUEL

TERMINALS

TO POWER

PLANTS

Required Respondents: Central fuel distribution terminals that serve to receive and distribute fuel to associated generating plants that cannot report individual fuel purchases at the plant level.

Fuel Terminal–Plant Relationships and Fuel Shipments: Report the plants that received fuel during the reporting period and the quantity of the fuel transferred to each plant from the terminal. The Plant ID and Name will be prepopulated after the initial report is made.

Report fuels in transit.

Report coal and petroleum coke in tons; liquid petroleum in barrels and natural gas in Mcf.

SCHEDULE 5.

No longer used. Form EIA-923 Schedules 5A to 5C have been combined with Schedules 3A to 3D.

SCHEDULE 6. NONUTILITY ANNUAL SOURCE AND DISPOSITION OF

ELECTRICITY

Required Respondents: Nonutility power plants defined as plants where costs are not recovered through rate-based regulation by a state regulatory body, municipal authority or a rural electric cooperative, but generally may market power in open wholesale markets, sell directly to consumers and/or power marketers/brokers, or consume self-generated power.

Report annual calendar year data for the source and disposition of electricity. Report in megawatthours (MWh) rounded to a whole number.

Source of Electricity

Gross Generation (Annual): Report the Total Gross Generation for the calendar year from all generators at the plant. Total Gross Generation should equal the sum of the gross generation reported on Schedules 3A, 3B, 3C, and 3D.

Other Incoming Electricity: Report all incoming electricity to the facility, whether from purchases, tolling agreements, transfers, exchanges, or other arrangements.

List at the bottom of the schedule the descriptions of “Other Incoming Electricity” (e.g., purchased, exchanged).

Total Sources: The sum of the total gross electricity generated and the total incoming electricity is automatically calculated and displayed on the form. Ensure that Total Sources equal the Total Disposition (see below).

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

Disposition

of

Electricity

Disposition

of

Electricity

Station Use: Report the amount of electricity that is used to operate and maintain the electric power plant of the facility (e.g., parasitic loads from auxiliary equipment), regardless of whether the electricity is produced at the plant or comes from another source. Do not include electricity used for pumping at pumped storage hydroelectric plants. Do not include electricity used for other purposes at industrial and commercial facilities (direct use).

Direct Use (Industrial and Commercial Sector Plants, both CHP and non-CHP): Report the amount of electricity consumed onsite for all operations other than electric power plant station use (see above), such as electricity consumed by manufacturing processes, district heating and/or cooling, hospital services, and campus services. Electricity consumed for Direct Use can be generated by the plant or purchased from an external source.

For plants for which Station Use and Direct Use cannot be separated, you may enter zero in Station Use, and the sum of Station Use and Direct Use in the Direct Use field. In such cases, provide a comment on Schedule 9.

Total Facility Use: The sum of station use and direct use is calculated on the form.

Retail Sales to Ultimate Customers: Report the amount of electricity sold directly to retail (end-use) customers (i.e., power that is not re-sold or distributed by another entity). Include unbilled electricity provided to affiliated and non-affiliated entities. Exclude power provided as part of a tolling agreement. Plants with retail sales are required to report Schedule 7B.

Sales for Resale: Report the amount of electricity sold for resale (wholesale sales). Plants with sales for resale must complete Schedule 7A.

Provided under Tolling Agreements: Report the amount of electricity provided under tolling agreements.

Other Outgoing Electricity: Report all other outgoing electricity from the facility, such as transfers and exchanges. Specify the nature of Other Outgoing Electricity on Schedule 9, Comments.

Total Disposition: The sum of station use, direct use, retail sales, sales for resale, and other outgoing electricity is automatically calculated on the form. Ensure that Total Disposition equals Total Sources (see above).

SCHEDULE 7A. ANNUAL REVENUE FROM SALES FOR RESALE

Required Respondents: Plants that report Sales for Resale on Schedule 6, Item 8, must report Schedule 7A.

Report revenue from Sales for Resale in thousand dollars, to the nearest whole number. This revenue should not include revenue from capacity payments, renewable energy credits, or other ancillary revenue streams.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE

7B. ANNUAL

RETAIL SALES,

REVENUES,

AND NUMBER

OF

CUSTOMERS

SCHEDULE

7B. ANNUAL

RETAIL SALES,

REVENUES,

AND NUMBER

OF

CUSTOMERS

Required Respondents: Plants that report retail sales on Schedule 6, Item 7, must report Schedule 7B.

Report by state and end-use customer sectors. Use Table 9 as a guide for the classification of your end- use customers, paying close attention to how your consumers should be organized into four sectors: Residential, Commercial, Industrial, and Transportation.

Complete an individual Schedule 7, Part B, for each state where customers are located.

Retail Sales: Report retail sales in megawatthours, by state and end-use sector.

Revenue: Report revenue associated with retail sales, by state and end-use sector.

Number of customers: Report the number of customers served, by state and end-use sector.

Note: Form EIA-861U previously collected the data now requested on Schedule 7B. Form EIA-861U is no longer required.

SCHEDULE 8. ANNUAL ENVIRONMENTAL INFORMATION

Required Respondents: Report environmental information on Schedule 8 for steam-electric (thermoelectric) power plants, including nuclear and combined-cycle plants, with a total steam turbine capacity greater than or equal to 10 megawatts as follows:

Plants with steam-electric capacity greater than or equal to 100 megawatts, report all parts of Schedule 8 (Parts A through D).

Plants with steam-electric capacity less than 100 megawatts but greater than or equal to 10 megawatts report only Schedule 8 Part C.

SCHEDULE 8. PART A. ANNUAL BY-PRODUCT DISPOSITION

Required Respondents: Thermoelectric power plants with a total steam turbine capacity of 100 megawatts or greater that produce combustion by-products.

Report by-products in thousand tons rounded to whole numbers. If actual data are not available, provide estimated values. Report the disposition of all combustion by-products produced during the reporting year. For by-products stored, but later sold or otherwise disposed of within the reporting year, report under the final disposition. Report by-products produced in previous years that were stored and subsequently sold or otherwise disposed of and provide the quantity from storage in a footnote on Schedule 9, Comments. Corresponding entries for cost of collection and disposal must be entered on Schedule 8, Part B.

Combustion By-products: If no combustion by-products were produced in the reporting year, place a check in the checkbox labeled, “Select if no combustion by-products were produced.”

Disposal: Report the quantity of each type of by-product under the appropriate column (On-Site Landfill, On-Site Pond, or Disposal Off-Site).

Beneficial Use: Report by-products put to beneficial use on-site or sold. If a by-product was stored in a landfill and subsequently put to beneficial use or sold, report the end disposition of the by-product.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

Storage:

Report by-products

stored

on

or

off site

for

subsequent

disposal

or

sale.

Storage:

Report by-products

stored

on

or

off site

for

subsequent

disposal

or

sale.

Combustion By-product Descriptions:

Fly ash from standard boiler/primary Particulate Collection Device (PCD) units: Report fly ash from units with no Flue Gas Desulfurization (FGD) system or with FGD systems located downstream of the PCD.

Fly ash from units with dry FGD: Report fly ash from units with spray dryer or duct injection systems, where fly ash and FGD by-products are collected in the same PCD. Do not include fly ash from Fluidized Bed Combustion (FBC) units.

Fly ash from FBC units: Report fly ash from Fluidized Bed Combustion (FBC) units.

Bottom ash from standard boiler units: Report bottom ash from standard boiler units and boiler slag from slagging combustors. Do not include bottom (bed) ash from FBC units, or slag from coal gasification units.

Bottom (bed) ash from FBC units: Report bottom (bed) ash from fluidized bed combustion (FBC) units.

FGD gypsum: Report by-products that are greater than 75% gypsum (CaS04●2H20), by weight.

Other FGD by-products: Report all FGD by-products not reported as “Fly ash from units with dry FGD units;” “Fly ash from FBC units;” “Bottom ash from standard boiler units;” “Bottom (bed) ash from FBC units;” and “FGD gypsum,” along with additives used to stabilize the FGD by-products.

Ash from coal gasification (IGCC) units: Report slag or solids extracted from the bottom of the gasifier, as well as fly ash removed downstream of the gasifier.

Other: Enter the amount of other by-products. Specify these “other” by-products on Schedule 9, Comments.

Steam sales: Report steam sales in million Btu (MMBtu).

SCHEDULE 8. PART B. FINANCIAL INFORMATION RELATED TO COMBUSTION BY-PRODUCTS

Required Respondents: Thermoelectric power plants with a total steam turbine capacity of 100 megawatts or greater that produced combustion by-products during the reporting year.

If actual data are not available, provide an estimated value. Cost data must be entered for all entries on Schedule 8A. If no cost was incurred, report zero.

Report all entries in thousand dollars, to the nearest whole number.

Operation and Maintenance (O&M) Expenditures during Year

Report costs for both collection and disposal of the indicated by-products. If the collection and disposal costs cannot be separated, place the total cost under the “Collection” line item, and provide a comment on Schedule 9, indicating that the costs cannot be separated. Exclude depreciation expense and cost of electricity consumed. Include all contract and self-service pollution abatement operation and maintenance expenditures for each line item.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

Fly

Ash

(1) and

Bottom Ash

(2):

Report all

material and

labor

costs associated

with

the

collection and

disposal of

the

fly

and bottom

ash from

all

sources, including

equipment operation

and maintenance

costs

(such as

particulate

collectors, conveyors,

hoppers, etc.).

Fly

Ash

(1) and

Bottom Ash

(2):

Report all

material and

labor

costs associated

with

the

collection and

disposal of

the

fly

and bottom

ash from

all

sources, including

equipment operation

and maintenance

costs

(such as

particulate

collectors, conveyors,

hoppers, etc.).

Flue Gas Desulfurization (3): Report all material and labor costs associated with the collection and disposal of the sulfur by-product, including equipment O&M costs.

Water Pollution Abatement (4): Report all operation and maintenance costs for material and/or supplies and labor costs, including equipment operation and maintenance (pumps, pipes, settling ponds, monitoring equipment, etc.), chemicals, and contracted disposal costs.

Other Pollution Abatement (5): Report operation and maintenance expenditures that are not allocated to a particular expenditure (e.g., expenditures to operate an environmental protection office or lab). Include expenses for conducting environmental studies for expansion or reduction of operations. Exclude all expenses for health, safety, employee comfort (OSHA), environmental aesthetics, research and development, taxes, fines, permits, legal fees, Superfund taxes, and contributions. Define other pollution abatement(s) in a comment on Schedule 9.

Capital Expenditures for New Structures and Equipment during Year, Excluding Land and Interest Expense

Report all pollution abatement capital expenditures for new structures and/or equipment made during the reporting year, regardless of the date these structures and/or equipment became operational. Do not leave Columns 7, 8, 9, and 10 blank. Enter zero if the line item is not applicable or if an estimate is not available, and enter a comment in Schedule 9. Specify the nature of the expenditures for these items in a comment on Schedule 9.

Air Pollution Abatement (7): Report new structures and/or equipment purchased to reduce, monitor, or eliminate airborne pollutants, including particulate matter (dust, smoke, fly ash, dirt, etc.), sulfur dioxides, nitrogen oxides, carbon monoxide, hydrocarbons, odors, mercury, acid gases, and other pollutants. Examples of air pollution abatement structures/equipment include flue gas particulate collectors, FGD units, continuous emissions monitoring equipment (CEMs), and nitrogen oxide control devices. Specify new structures/equipment in a comment on Schedule 9.

Water Pollution Abatement (8): Report new structures and/or equipment purchased to reduce, monitor, or eliminate waterborne pollutants, including chlorine, phosphates, acids, bases, hydrocarbons, sewage, and other pollutants. Examples include structures/equipment used to treat thermal pollution; cooling, boiler, and cooling tower blowdown water; coal pile runoff; and fly ash waste water. Do not include expenditures for treatment of water prior to use at the plant. Specify new structures/equipment in a comment on Schedule 9.

Solid/Contained Waste (9): Report new structures/equipment purchased to collect and dispose of objectionable solids or contained liquids. Examples include purchases of storage facilities, trucks, etc., to collect, store, and dispose of solid/contained waste. Include equipment used for handling solid/contained waste generated as a result of air and water pollution abatement. Specify new structures/equipment in a comment on Schedule 9.

Other Pollution Abatement (10): Report amortizable expenses and purchases of new structures and or equipment when such purchases are not allocated to a particular unit or item. Examples include charges for the purchases of facilities to control hazardous waste, radiation, and noise pollution. Exclude all equipment purchased for aesthetics purposes. Specify new structures/equipment in a comment on Schedule 9.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

By-product

Sales

Revenue

during

Year: If

there

were no

by-product

sales revenues,

report a

zero value

in

Column 16

(“Total”).

Report the

revenue, if

any, for

each

listed by-product.

Specify the

nature of

“Other

Pollution Abatement”

revenue in

a comment

on

Schedule 9.

If

the

revenue for

a by-product

is

less

than $500,

enter

a zero

and

enter a

comment on

Schedule 9

with

the actual

dollar amount.

Report

revenue

for gypsum

on Schedule

8, Part

B,

Column

14,

and

note this

activity

in a

comment on

Schedule

By-product

Sales

Revenue

during

Year: If

there

were no

by-product

sales revenues,

report a

zero value

in

Column 16

(“Total”).

Report the

revenue, if

any, for

each

listed by-product.

Specify the

nature of

“Other

Pollution Abatement”

revenue in

a comment

on

Schedule 9.

If

the

revenue for

a by-product

is

less

than $500,

enter

a zero

and

enter a

comment on

Schedule 9

with

the actual

dollar amount.

Report

revenue

for gypsum

on Schedule

8, Part

B,

Column

14,

and

note this

activity

in a

comment on

Schedule

9. Report the total revenue for the sale of by-products in Column 16. If the revenue reported was for the sale of stockpiled by-products from previous years, enter a comment on Schedule 9.

SCHEDULE 8. PART C. AIR EMISSIONS CONTROL INFORMATION

Required Respondents: Thermoelectric or combined-cycle power plants with a total steam turbine capacity greater than or equal to 10 megawatts.

General Instructions

Report the actual rate and removal efficiency for air emissions controlled by each equipment type or control strategy identified by unique IDs. The IDs must be consistent with those reported on the Form EIA-860, Schedule 6A. Where applicable, base data on Continuous Emissions Monitoring System (CEMS) data.

Report emission removal efficiencies to the nearest 0.1 percent by weight. Report emission rates as pounds per million Btu of fuel burn to the nearest 0.01 lb/MMBtu.

Emissions Control Equipment or Technology Type: Report the code for the type of equipment or strategy for the control of air emissions. The codes are prepopulated on the form. If a correction is needed, please contact EIA referencing what needs to be added or updated from Table 6.

Emission Control IDs: Equipment ID is prepopulated from the previous year. If the information is not prepopulated or is incorrect, please contact EIA. IDs must be consistent with those reported on Schedule 6 of the Form EIA-860.

Equipment Status: Select from the equipment status codes in Table 4. Equipment status for each equipment type is prepopulated for e-file users.

Table 4. Equipment Status Codes

-

Code

Status

OP

Operating (in commercial service or out of service within 365 days)

OS

Out of service (365 days or longer)

RE

Retired (no longer in service and not expected to be returned to service)

SB

Standby (Reserve)

OA

Temporarily out of service (less than 365 days)

Hours in Service: Enter the total hours the control was in service during the reporting year (to the nearest hour).

NOx Emission Rate (Entire Year): For each equipment or strategy type and unique ID, enter the actual controlled (or uncontrolled) nitrogen oxides emission rate, in pounds per million Btu, based on data from CEMS, where possible. Where CEMS data are not available, report the nitrogen oxides emission rate, based on the method used to report emissions data to environmental authorities.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

NOx

Emission

Rate

(May

to

September):

For

each equipment

or

strategy type

and unique

ID, enter

the

actual controlled

(or

uncontrolled)

nitrogen oxides

emission rate

during the

ozone season

(May

to

September), in

pounds

per million

Btu,

based

on

data from

CEMS, where

possible. Where

CEMS

data

are

not available,

report nitrogen

oxides

rates, based

on

the

method

used

to

report

emissions

data

to

environmental

authorities.

NOx

Emission

Rate

(May

to

September):

For

each equipment

or

strategy type

and unique

ID, enter

the

actual controlled

(or

uncontrolled)

nitrogen oxides

emission rate

during the

ozone season

(May

to

September), in

pounds

per million

Btu,

based

on

data from

CEMS, where

possible. Where

CEMS

data

are

not available,

report nitrogen

oxides

rates, based

on

the

method

used

to

report

emissions

data

to

environmental

authorities.

Particulate Matter Emissions Removal Rate: For each equipment or strategy type and unique ID, enter the average annual emission removal rate for particulate matter.

Particulate Matter Removal Efficiency at Annual Operation Factor: For each equipment or strategy type and unique ID, enter removal efficiency, based on the annual operating factor. If actual data are unavailable, provide estimates, based on equipment design performance specifications.

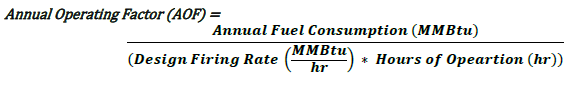

Annual operating factor, as given by the formula below, is defined as annual fuel consumption (MMBtu) divided by the product of the boiler design firing rate (MMBtu per hour) and hours of operation per year.

P

articulate

Matter

Tested

Removal

Efficiency

Rate

(at

100%

Load):

For

each

equipment

or

strategy

type

articulate

Matter

Tested

Removal

Efficiency

Rate

(at

100%

Load):

For

each

equipment

or

strategy

type

and unique ID, enter the tested efficiency for the removal of particulate matter. If not tested at 100% load, provide the load at which the test was conducted in a comment on Schedule 9. If no test was conducted, leave the test date and the tested efficiency field blank.

Particulate Matter Removal Efficiency Rate Test Date: Enter the date of the latest efficiency test for the removal of particulate matter. If no test was conducted, leave the test date and the tested efficiency field blank.

Sulfur Dioxide Emissions Removal Efficiency at AOF: For each equipment or strategy type and unique ID, enter removal efficiency for sulfur dioxide, based on the annual operating factor (see above for AOF description). If actual data are unavailable, provide estimates, based on equipment design performance specifications.

Sulfur Dioxide Tested Removal Efficiency Rate (at 100% Load): For each equipment or strategy type and unique ID, enter the tested efficiency for the removal of sulfur dioxide. If not tested at 100% load, provide the load at which the test was conducted in a comment on Schedule 9. If no test was conducted, leave the test date and the tested efficiency field blank.

Sulfur Dioxide Removal Efficiency Rate Test Date: Enter the date of the latest efficiency test for the removal of sulfur dioxide. If no test was conducted, leave the test date and the tested efficiency field blank.

Quantity of Flue Gas Desulfurization Sorbent Used: Enter the quantity of FGD sorbent used by the unit during the reporting period (to the nearest 0.1 thousand tons).

Electrical Energy Consumption: Enter the Electrical Energy Consumed by the FGD unit during the reporting period (in megawatthours).

Mercury Removal Efficiency and Mercury Emissions Rate: Enter either the removal efficiency for mercury emissions to the nearest 0.1% by weight or if not available, enter the rate of mercury emissions in pounds per

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

trillion Btu. If both the mercury removal efficiency and mercury emissions rate are readily available, the option to provide both is allowed.

Specifically for the mercury emissions rate, for each equipment or strategy type and unique ID, enter the actual controlled (or uncontrolled) mercury emission rate, in pounds per trillion Btu (lbs/TBtu), based on data from CEMS, where possible. Where CEMS data are not available, report the mercury emission rate, based on the method used to report emissions data to environmental authorities

Acid Gases Removal Efficiency: Enter the removal efficiency for acid gas emissions, such as HCl.

FGD Operation and Maintenance Expenditures during the Year (Excluding Electricity)

Report the O&M Expenditures for the Flue Gas Desulfurization Units, excluding electricity, in thousand dollars for each category. Please report costs in nominal dollars and do not convert into real dollars, even if materials were purchased many years ago at reduced prices.

Unit ID: Unit ID must be consistent with the ID provided for the equipment in the above section. If not prepopulated, contact EIA.

Feed Materials and Chemicals: The delivered costs of all sorbents and chemicals used in the FGD unit to remove SO2 from the flue gases, including any costs of processing the sorbents after receipt.

Labor and Supervision: All labor and supervision costs required to run the FGD throughout the year.

Waste Disposal: All costs associated with disposing of waste materials from the FGD unit throughout the year.

Maintenance Materials and All Other Costs: All costs associated with the acquisition of other maintenance materials and any other costs not associated with any other cost category.

Total: The total of all of the above costs.

|

FORM EIA-923 POWER PLANT OPERATIONS REPORT INSTRUCTIONS |

OMB No. 1905-0129 Approval Expires: xx/xx/xxxx

|

SCHEDULE 8. PART D. MONTHLY COOLING SYSTEM OPERATIONS

Required Respondents: Thermoelectric power plants (organically fueled, nuclear, and combined-cycle) with a total steam capacity of 100 megawatts or greater.

Report data for each respective reporting month in the reporting year.

Complete a separate row for each cooling system, unless inseparable, then choose PLANT for the cooling system ID.

If actual data are not available, provide estimated values.

If the source of cooling water is a well or municipal water system, do not complete the Cooling W ater Temperature sections.

An

illustrated

appendix

is

included at

the

end

of

the

specific instructions

for guidance

in