American Healthy Homes Survey II

American Healthy Homes Survey II

AHHS II Appendix A_Field Protocols Questionnaire Informed Consent._21nov17

American Healthy Homes Survey II

OMB: 2539-0026

Appendix A - American Healthy Homes Survey II (AHHS II)

Field Sampling Protocols, Resident Questionnaire and Informed Consent

The AHHS II is a follow-up to the American Healthy Homes Survey (AHHS) conducted 2005-2006, and the National Survey of Lead and Allergens in Housing (NSLAH) conducted 1998-1999. Sponsored by the US Department of Housing and Urban Development (HUD) and the Environmental Protection Agency (EPA), it is aimed at monitoring changes in the level of health hazards in homes over time and in refining understanding of certain patterns identified in the AHHS and NSLAH. The design of the AHHS II is intended to maximize comparability of these surveys where appropriate (e.g., environmental sampling methodologies), while reflecting significant scientific and technological advances and evolution of the specific housing conditions of greatest interest to HUD.

The objectives, design, field operations and reporting requirements of the AHHS II are very similar to those to AHHS. Key differences are:

Allergen sampling will not be conducted.

Household dust and soil sampling for arsenic is not part of the design.

Evaluation of the potential for unintentional injuries, such as from falls, fires, burns, electrical faults, carbon monoxide, etc., has been added.

Air sampling for formaldehyde will be conducted.

Sampling for lead in household water and lead service lines will be included.

Survey objectives will be addressed by collecting a wide range of data including demographic data and various environmental data, from a nationally representative sample of approximately 600 housing units (dwelling units) across the United States (data on 1,131 units were collected in AHHS).

The dwelling units (DUs) have been randomly selected from 58 Primary Sampling Units (PSUs). For AHHS II, PSUs are counties or groups of contiguous counties with a minimum population of 15,000 in the 2000 Census and an end-to-end distance generally not exceeding 100 miles. Within each PSU between 4 and 12 smaller geographical areas called segments have been selected. Most PSUs consist of 5 segments.

At the start of the study, a total of 16-20 DUs in each PSU will be released for recruitment. Interviewers will attempt to recruit all released DUs. Each DU recruited will be scheduled by the Interviewer to be tested. A two-person team will do testing of each recruited DU: the Interviewer who recruited the DU and a licensed lead risk assessor referred to in this study as a Technician. Testing will include a resident questionnaire and collection of a wide variety of measurements. A summary of the environmental sampling is provided in Table INTRO-1. A summary of the analytical methods used to analyze the collected samples is presented in Table INTRO-2.

Table INTRO-1. Summary of Environmental Sampling |

||||||

IDa |

Information Captured or Target Analyte |

Data Collection Method or Sampling Media |

Tests or Samples per DU |

Special Handling Requirements |

Maximum Media Count |

Notes |

Collected by Interviewer |

||||||

I2/I3 |

Lead in water (incremental) |

Bulk 1-liter |

1 |

acidified at lab and wait >24 hrs before analysis |

600 |

wide mouth LDPE bottle |

I6 |

Mold by PCR |

Vacuum dust (resident vacuum bag) |

0-1 |

none |

600 |

|

I8 |

Mold (by PCR) |

Vacuum dust |

1 |

none |

600 |

|

I9 |

Mold (by PCR) |

Dust wipe (Swiffer™) |

1 |

frozen after collection |

116 |

2 per PSU (58 PSUs) |

|

|

|

|

|

|

|

Collected by Technician |

||||||

T1 |

Formaldehyde in air |

Absorption tube |

1 plus 1 blank/PSU |

frozen after collection |

716 |

Count includes 1 spiked QC/PSU |

T2 |

Lead based paint |

XRF |

>40 readings plus QC |

not applicable |

not applicable |

Testing of water supply line for Pb included here, if it can be accessed. |

T3 |

Lead in dust |

Dust wipe |

9 plus 1 blank |

none |

6600 |

Count includes 10% QC |

T4 |

Pesticides |

Dust wipe |

2 plus 1 blank/PSU |

frozen after collection |

1258 |

|

T5 |

Lead in soil |

Soil |

0 to 6 |

dried at room temperature and sieved to <2 mm, sub-sampled, then sent to EPA |

2640 |

Count assumes mean of 4 samples/DU and, for lead in soil, includes 10% QC. |

Bioavailable lead |

sieved to <250 µm |

2400 |

||||

aIdentifies the protocol containing detailed instructions for the tests or sample collection. |

||||||

Table INTRO-2. Summary of Analytical Methods |

||||

IDa |

Information Captured or Target Analyte |

Sample Preparation |

Analytical Method |

Detection Limits |

Collected by Interviewer |

||||

I2/I3 |

Lead in water (incremental) |

Acidified at lab to pH<2 with 1:1 nitric acid and wait >24 hrs before analysis |

SMb 3113B (GFAA) or ICP/MS |

Pb: 3 µg/L |

I6 |

Mold by PCR |

Sieved to 300 µm and extracted in neutral buffer and shaken in the bead beater to release the DNA. The mold DNA is purified using the DNA-EZ extraction kit. |

MSQPCR developed by EPA (US Patent No.6,387,652). |

not defined |

I8 |

Mold (by PCR) |

|||

I9 |

Mold (by PCR) |

|||

|

|

|

|

|

Collected by Technician |

||||

T1 |

Formaldehyde in air |

none |

modified NIOSH 2016 (HPLC- UV detection) |

0.12 ppb for 3-hour sample at 1.5LPM |

T2 |

Lead based paint by XRF |

none |

Direct field measurement using field portable XRF |

Meets HUD EPA PCS requirements |

T3 |

Lead in dust |

EPA 3050B-M |

EPA 6010C (ICP) |

Pb: 20 mg/kg (RL) |

T4 |

Pesticides |

Extracted in dichloromethane and concentrated using solid-phase extraction cartridgeb |

GCMSb |

variable depending on pesticide |

T5 |

Lead in soil |

EPA 3050B-M |

EPA 6010C (ICP) |

Pb: 20 mg/kg (RL) |

Bioavailable lead |

EPA Method 9200.2-86: Buffered leach (pH 1.5) mimicking stomach acid conditions |

EPA Method 3051A |

not defined |

|

aIdentifies the protocol containing detailed instructions for the tests or sample collection. bStout, D.M., et.al.; American Healthy Homes Survey A National Study of Residential Pesticides Measured from Floor Wipes; Environ. Sci. Technol., 2009, 43, 4293-4300 |

||||

LIST OF GENERAL (OFFICE) STUDY PROTOCOLS

Item Page

G2- DU RELEASE TO INTERVIEWERS 1

G2.1 INTRODUCTION

G2.2 DU ID NUMBER ASSIGNMENTS

G2.3 SAMPLE COLLECTION SUMMARY

G2.4 PSU SUMMARY SHEET

G2.5 ADJUSTMENTS TO RELEASED DUs FOR REALIZED RECRUITMENT RATE

G2.6 RELEASE PROCEDURE

Advance Letter - Longitudinal 4

Advance Letter - New 5

Advance Letter – Longitudinal – Hand Delivered 6

Advance Letter – New – Hand Delivered 7

No Contact Letter - Longitudinal 8

No Contact Letter - New 9

Refusal Letter - Longitudinal 10

Refusal Letter - New 11

PSU Summary Sheet 12

G6- SUMMARY OF TESTING IN EACH DU 13

Table G6-1. Planned Division of Labor for Testing Efforts in Each DU 13

G7-TELEPHONE VERIFICATION OF DATA COLLECTION 14

Telephone Verification Log 15

G8 - ISSUANCE OF PARTICIPANT REPORTS 16

Respondent Report - Lead and/or Safety Hazards Exist 17

Respondent Report - No Lead and/or Safety Hazards Exist 20

LIST OF INTERVIEWER PROTOCOLS

Item Page

I0/T0 - GENERAL PROCEDURES FOR MINIMIZING CONTAMINATION 21

I2- RECRUITMENT SCREENING 23

Cover Sheet for Recruiting Questionnaire Form Set 27

Appointment Control Log and In-Person Contact Record 28

Recruitment Questionnaire 29

Appointment Reminder Card 34

Scheduling Calendar 35

Figure I2-1 - Bottle label for drinking water sample 36

FAQs 37

I3- INTRODUCTION AND INFORMED CONSENT 43

Cover Sheet for Resident Questionnaire Set 46

Introduction - part of Resident Questionnaire 47

Informed Consent 48

Drinking Water Sample Collection Log

LIST OF INTERVIEWER PROTOCOLS - continued

Item Page

I4- ROOM INVENTORY 53

Room Inventory part of Resident Questionnaire 56

Random Number Table for Random Selections 57

I5- RESIDENT QUESTIONNAIRE 58

Remaining portions of Resident Questionnaire 59

Break-off Report 80

I6- INTERIOR WALKTHROUGH OBSERVATIONS 82

Household Walkthrough Observations forms 84

Vacuum Cleaner Bag Collection 88

I7- ROOM OBSERVATION and BUILDING MOISTURE MEASUREMENTS 90

Room Observation Form - KIT 94

Room Observation Form - CLA 95

Room Observation Form - BR 96

Room Observation Form - Other Room 97

Room Observation Form - Basement 98

Building Materials - Moisture Testing Log 99

I8- FUNGI VACUUM DUST SAMPLING 100

Fungi Vacuum Dust Sample Collection Log 103

I9- DUST WIPE SWIFFER™ SAMPLE 105

Dust wipe SWIFFER™ Sample Collection Log 106

107

(Removed; sample collected in I3) 108

110

111

I11- EXTERIOR WALKTHROUGH OBSERVATIONS 112

Exterior Conditions Log 113

LIST OF FIELD TECHNICIAN PROTOCOLS

Item Page

T1- FORMALDEHYDE IN AIR SAMPLING 114

Cover Sheet for Technician Form Set 119

Formaldehyde Collection Sample Log 120

T2- LEAD-BASED PAINT TESTING (using XRF) 122

Table T2-1. Data Collection Programming on the Heuresis model Pb200i 125

LBP Testing Codes and Checklist Instructions 126

LBP Testing Checklist for Miscellaneous Tests 127

LBP Testing Checklist for KIT 128

LBP Testing Checklist for CLA 129

LBP Testing Checklist for BR 130

LBP Testing Checklist for Other Room 131

LBP Testing Checklist for Exterior 132

Random Number Table for Random Selections 133

T3- LEAD DUST WIPE SAMPLING 134

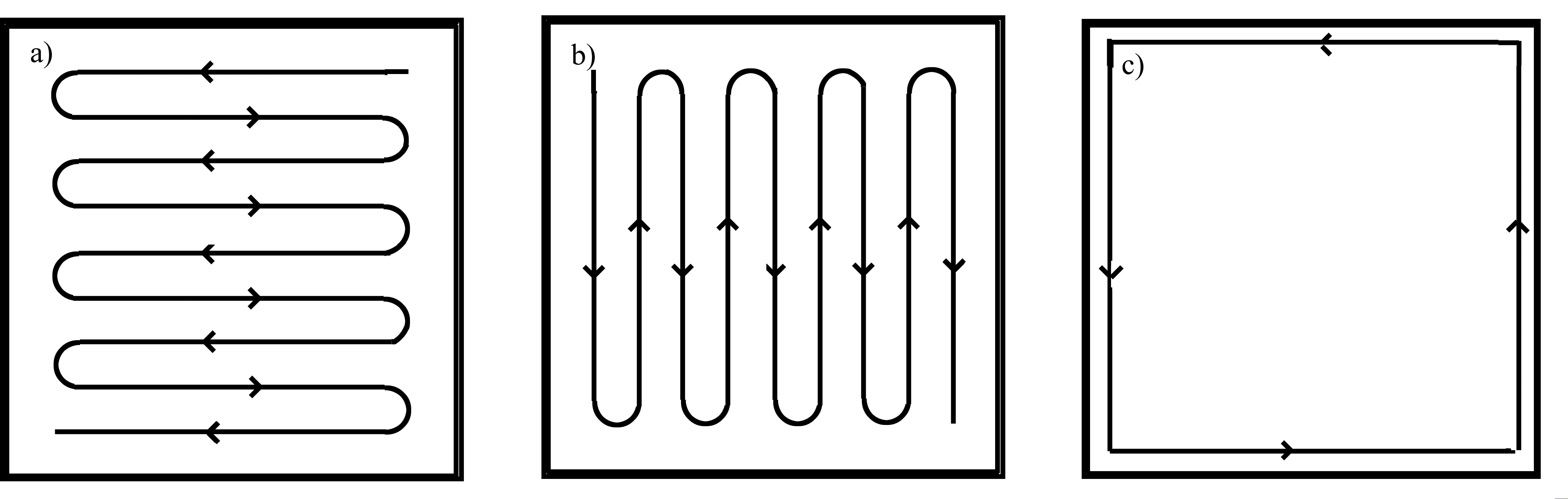

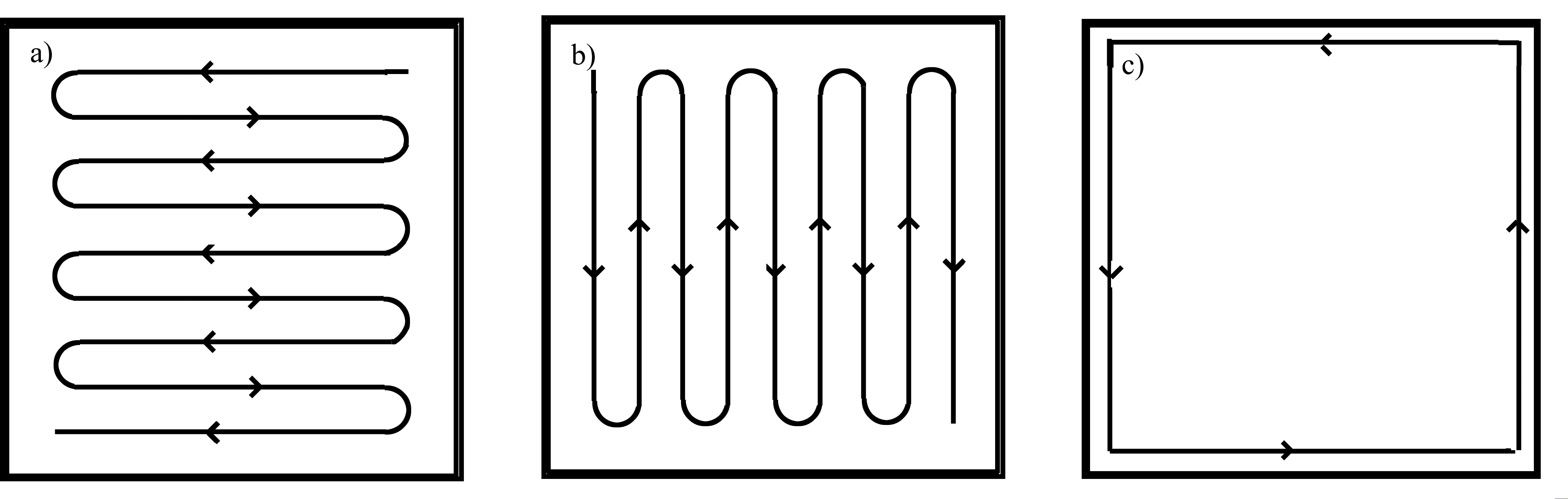

Figure T3-1: Schematic of a side-to-side overlapping "S" wiping pattern 137

Figure T3-2: Schematic of a side-to-side overlapping "Z" wiping pattern 137

Lead Wipe Sample Collection Log - KIT 138

Lead Wipe Sample Collection Log - CLA 139

Lead Wipe Sample Collection Log - BR 140

Lead Wipe Sample Collection Log - Other Room 141

Lead Wipe Sample Collection Log - Entry 142

T4- PESTICIDE WIPE SAMPLING 144

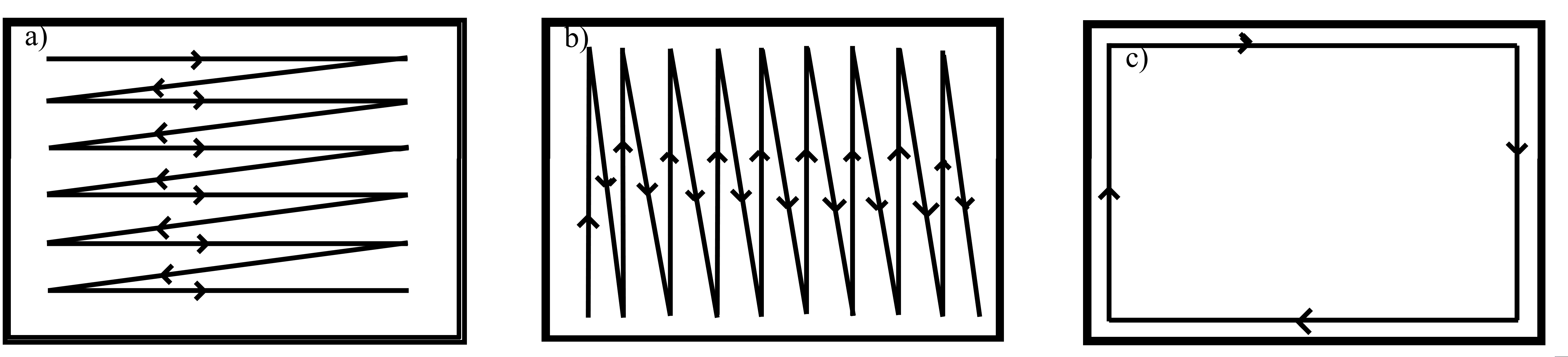

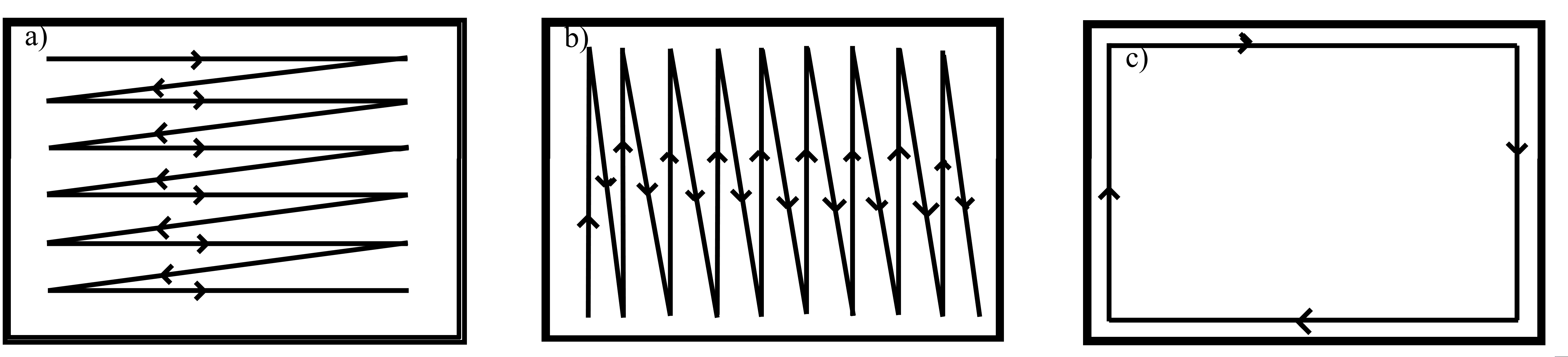

Figure T4-1: Schematic of a side-to-side overlapping "S" wiping pattern 147

Figure T4-2: Schematic of a side-to-side overlapping "Z" wiping pattern 147

Pesticide Wipe Sample Collection Log 148

T5- LEAD SOIL SAMPLING 150

Random Number Table for Random Selections 155

Lead Soil Sample Collection Log 156

G2- DU RELEASE TO INTERVIEWERS |

||

Staff Involved: |

Assigned QT Office Staff |

|

Overview: The average number of DUs to be recruited and completed is 10.3 per PSU. Initially, for each PSU, a base draw of 4 dwelling units (DUs) in each segment (typically 16-20 DUs/PSU) will be released to the Interviewer for recruitment. These DUs are given a SAMP TYPE designation of M1, M2, M3, and M4. An additional draw of 2 DUs in each segment will be held in reserve. These DUs are given a SAMP TYPE designation of R1 and R2. The Interviewer will follow the full recruiting protocol for each DU released to him/her. At least four attempts will be made to contact a resident at each DU. Attempts will be made at different times of the day and on different days of the week. For example, if the first contact during the day on a weekday is unsuccessful, the second attempt might be made on a weekday evening, followed by a third attempt on the weekend, etc. The recruiting effort for a DU will be considered complete only if contact is made and a data collection visit is agreed to or refused, or if four unsuccessful attempts are made to contact a resident. |

||

Data Recording on: |

AHHS II Recruitment Tracking Spreadsheet |

|

G2.1 INTRODUCTIONQuanTech headquarters staff will aid the recruiting in several ways:

1. AHHS II Recruitment Tracking Spreadsheet. An Excel workbook will be created and used at QuanTech headquarters (QT) to track all the recruiting and DU completion efforts as well as the general support efforts provided by staff at QT.

2. Advance Letters. QuanTech headquarters (QT) will mail an Advance Letter to each selected address about one week before the Interviewer arrives in the PSU. The Advance Letter explains the survey and the incentives for participation, and alerts the recipient to the pending visit from the Interviewer. Included with this letter is a token cash incentive of $1. These letters will be sent in Official HUD envelopes. The Interviewer will also hand a copy of the Advance Letter (as an example) to the resident when contact is made. If nobody is home when the Interviewer first visits a DU, and the home is not obviously vacant, an Advance Letter- Hand Delivered will be hung in a clear plastic doorknob hanger bag on the main entry door of the DU. This copy will explain that the Interviewer stopped by and will return soon.

3. No Contact Letter. If four attempts to contact a resident at a selected DU are unsuccessful, and for DUs where access is impossible, e.g., some gated communities or apartment buildings with a doorman1, a No Contact Letter will be sent by Priority Mail. These letters will also be sent in Official HUD envelopes. The No Contact Letter elaborates on the importance of the survey and the incentives for participation and provides a toll-free number to call to schedule a visit.

4. Refusal Letter. Finally, in the event of a refusal, a Refusal Letter will be sent by sent by Priority Mail to the potential respondent. The Refusal Letter will reiterate the reasons for participating and the incentives for doing so, and will provide a toll-free number for the potential respondent to call.

There are two versions of each letter: one for longitudinal addresses and one for new addresses. The wording differences are minor.

G2.2 DU ID NUMBER ASSIGNMENTS

The DU ID to be used by the Interviewer and Technician combines 3 data fields shown on the AHHS main and reserve sample DU addresses list, and has the following format:

XXX-YYY-ZZ

Where XXX is the PSU ID identifier from the AHHS Main and reserve sample DU addresses list identifier; a number from 101 to 999

YYY is the AHHS SEGID identifier; a number from 001 to 999

ZZ is the SAMP TYPE identifier from the AHHS Main and reserve sample DU addresses list identifier, M1, M2, M3, or M4 for main sample draw and R1 or R2 for reserve sample draw.

G2.3 SAMPLE COLLECTION SUMMARY

Sample collection for the targeted analyses (see Table G3-3 in protocol G3) will be performed in All DUs. In AHHS II, a pesticide sample is to be collected in every DU, with an additional pesticide QC sample (field blank) collected in the first DU visited in each PSU (In AHHS I, pesticide samples were not collected in every DU). A Swiffer™ dust wipe sample for mold is to be collected in the first two DUs visited in each PSU, with an additional Swiffer™ QC dust wipe sample (field blank) collected in the first DU visited in each PSU.

G2.4 PSU SUMMARY SHEET

The AHHS main and reserve sample DU addresses listing provided to the Interviewer in the Recruitment Kit (A) contains both the main draw DUs and the reserve draw DUs. A PSU Summary Sheet (see form at the end of this protocol) is added to this information to specify the DUs that are to be recruited.

G2.5 ADJUSTMENTS TO RELEASED DUs FOR REALIZED RECRUITMENT RATE

QuanTech will attempt to complete data collection in all recruited DUs. However, it is expected that a small number of recruited DUs will not be completed (such as in the case of refusal to sign the informed consent, or a "mid-interview" refusal where the respondent decides to terminate the visit before data collection is complete). After approximately 20 PSUs have been completed, an evaluation of the response rate will be made. If the response rate for the first 20 PSUs is running low, QuanTech will release additional DUs from the reserve draws in the second 20 PSUs. The number of reserves released will be the number needed, based on the response rate for the first 20 PSUs, to bring the number of completed DUs in the first 40 PSUs up to the desired total of approximately 400 with high probability. Conversely, if the response rate is running high, a downward adjustment in the number of DUs released will be made. An additional response rate evaluation will be conducted after 40 PSUs are completed and adjustments made as needed.

G2.6 RELEASE PROCEDURE

1. Verify DUs to be released. Discuss with the Project Director which DUs are to be released to the Interviewers. These entries are also to be made in a master spreadsheet containing all the DU listings.

2. Complete the PSU Summary Sheet. Complete the PSU Summary Sheet and put it in the Recruiting Supplies Kit (A) ENVELOPE A - DU Listings containing the AHHS main and reserve sample DU addresses listings..

3. Mail out Advance Letter. One week before the start of recruiting at a given PSU, mail the Advance Letter containing the token $1 incentive to all released DUs. There are two categories of advance letters to be mailed: one for longitudinal addresses (those that were included in the AHHS I) and one for new addresses (those not included in AHHS I). The master spreadsheet is configured to indicate which addresses belong to each category.

4. Update Tracking Records. Indicate, in the master spreadsheet containing the DU listings, the date the initial contact letters were sent and store this copy in the project records by PSU. Update the electronic version of the spreadsheet as time permits.

OMB No. xxxx-xxxx

expires: mm/dd/2018

|

|||||||

<date>

Dear Sir or Madam:

Ten years ago, this home was in the first American Healthy Homes Survey. You may not have lived here then. We selected it again as one of only 600 homes for the second American Healthy Homes Survey. Each home stands for thousands more. As an incentive to participate, you will receive a check for $130 upon completion of the survey in your home, a report on certain chemical and mold exposures, and safety hazards, in your home and, if you accept it, a report on lead paint hazards in your home. Reports like these can cost hundreds of dollars.

We will test for:

Lead in paint, dust and soil, that can harm young children.

Lead in your water. We will ask you to collect a water sample for this test.

Pesticide residues on floors.

Formaldehyde, found in carpets, furniture or particle board.

Mold in your home, whether you can see it or not.

Safety hazards such as carbon monoxide; smoke detectors that don’t work; electrical hazards; water that is too hot for children or the elderly; and, things that can cause trips and falls.

The survey will give you valuable information to protect your health and safety. It will also help the Government to understand how common these health and safety exposures are in the country. Even if your home does not have any of these hazards, you are still giving valuable information to the study.

The Department of Housing and Urban Development (HUD) and the Environmental Protection Agency (EPA) are funding this survey. It is being conducted by QuanTech, a contractor. In a few days, an interviewer from QuanTech will contact you. She or he will show you official ID and ask you some short, easy questions about you and your home. These questions will help see if your home can participate in the survey. For example, vacation homes are excluded from the study. If your home is eligible, we hope you will participate so that our results will be complete. Answering the questions is completely voluntary, and you may choose not to answer any question. Your answers, and other data collected in your home, will be kept private to the extent permitted by law under the Privacy Act of 1974. HUD and EPA will use the data only for statistical research and reports. We have enclosed a small token of appreciation as a way of saying thanks for your help.

If you have any questions or if you want to speak to a study representative at any time, please call Dr. David Cox, QuanTech, at 1-800-229-5220. We thank you in advance for your cooperation.

Sincerely,

Warren Friedman

Senior Advisor to the Director

This survey is a Federal program authorized under the Residential Lead-Based Paint Hazard Reduction Act and the National Environmental Policy Act.

No. xxxx-xxxx

expires: mm/dd/2018

|

|||||||

<date>

Dear Sir or Madam:

Your home is one of 600 selected to take part in an important national survey, the second American Healthy Homes Survey. Each home stands for thousands more. As an incentive to participate, you will receive a check for $130 upon completion of the survey in your home, a report on certain chemical and mold exposures, and safety hazards, in your home and, if you accept it, a report on lead paint hazards in your home. Reports like these can cost hundreds of dollars.

We will test for:

Lead in paint, dust and soil, that can harm young children.

Lead in your water. We will ask you to collect a water sample for this test.

Pesticide residues on floors.

Formaldehyde, found in carpets, furniture or particle board.

Mold in your home, whether you can see it or not.

Safety hazards such as carbon monoxide; smoke detectors that don’t work; electrical hazards; water that is too hot for children or the elderly; and, things that can cause trips and falls.

The survey will give you valuable information to protect your health and safety. It will also help the Government to understand how common these health and safety exposures are in the country. Even if your home does not have any of these hazards, you are still giving valuable information to the study.

The Department of Housing and Urban Development (HUD) and the Environmental Protection Agency (EPA) are funding this survey. It is being conducted by QuanTech, a contractor. In a few days, an interviewer from QuanTech will contact you. She or he will show you official ID and ask you some short, easy questions about you and your home. These questions will help see if your home can participate in the survey. For example, vacation homes are excluded from this survey. If your home is eligible, we hope you will participate so that our results will be as complete as possible. Answering the questions is completely voluntary, and you may choose not to answer any question. Your answers, and other data collected in your home, will be kept private to the extent permitted by law under the Privacy Act of 1974. HUD and EPA will use the data only for statistical research and reports.

We have enclosed a small token of appreciation as a way of saying thanks for your help.

If you have any questions or if you want to speak to a study representative at any time, please call Dr. David Cox, QuanTech, at 1-800-229-5220. We thank you in advance for your cooperation.

Sincerely,

Warren Friedman

Senior Advisor to the Director

This survey is a Federal program authorized under the Residential Lead-Based Paint Hazard Reduction Act and the National Environmental Policy Act.

OMB No. xxxx-xxxx

expires: mm/dd/2018

|

|||||||

<date>

Dear Sir or Madam:

Ten years ago, this home was in the first American Healthy Homes Survey. You may not have lived here then. We selected it again as one of only 600 homes for the second American Healthy Homes Survey. Each home stands for thousands more. As an incentive to participate, you will receive a check for $130 upon completion of the survey in your home, a report on certain chemical and mold exposures, and safety hazards, in your home and, if you accept it, a report on lead paint hazards in your home. Reports like these can cost hundreds of dollars.

. We will test for:

Lead in paint, dust and soil, that can harm young children.

Lead in your water. We will ask you to collect a water sample for this test.

Pesticide residues on floors.

Formaldehyde, found in carpets, furniture or particle board.

Mold in your home, whether you can see it or not.

Safety hazards such as carbon monoxide; smoke detectors that don’t work; electrical hazards; water that is too hot for children or the elderly; and, things that can cause trips and falls.

The survey will give you valuable information to protect your health and safety. It will also help the Government to understand how common these health and safety exposures are in the country. Even if your home does not have any of these hazards, you are still giving valuable information to the study.

The Department of Housing and Urban Development (HUD) and the Environmental Protection Agency (EPA) are funding this survey. It is being conducted by QuanTech, a contractor. An interviewer from QuanTech has delivered this letter to your home. If you were not home to receive the letter in person, the Interviewer will stop by again shortly. She or he will show you official ID and ask you some short, easy questions about you and your home. These questions will help see if your home can participate in the survey. For example, vacation homes are excluded from the study. If your home is eligible, we hope you will participate so that our results will be complete. Answering the questions is completely voluntary, and you may choose not to answer any question. Your answers, and other data collected in your home, will be kept private to the extent permitted by law under the Privacy Act of 1974. HUD and EPA will use the data only for statistical research and reports.

If you have any questions or if you want to speak to a study representative at any time, please call Dr. David Cox, QuanTech, at 1-800-229-5220. We thank you in advance for your cooperation.

Sincerely,

Warren Friedman

Senior Advisor to the Director

This survey is a Federal program authorized under the Residential Lead-Based Paint Hazard Reduction Act and the National Environmental Policy Act.

OMB No. xxxx-xxxx

expires: mm/dd/2018

|

|||||||

<date>

Dear Sir or Madam:

Your home is one of 600 selected to take part in an important national survey, the second American Healthy Homes Survey. Each home stands for thousands more. As an incentive to participate, you will receive a check for $130 upon completion of the survey in your home, a report on certain chemical and mold exposures, and safety hazards, in your home and, if you accept it, a report on lead paint hazards in your home. Reports like these can cost hundreds of dollars.

We will test for:

Lead in paint, dust and soil, that can harm young children.

Lead in your water. We will ask you to collect a water sample for this test.

Pesticide residues on floors.

Formaldehyde, found in carpets, furniture or particle board.

Mold in your home, whether you can see it or not.

Safety hazards such as carbon monoxide; smoke detectors that don’t work; electrical hazards; water that is too hot for children or the elderly; and, things that can cause trips and falls.

The survey will give you valuable information to protect your health and safety. It will also help the Government to understand how common these health and safety exposures are in the country. Even if your home does not have any of these hazards, you are still giving valuable information to the study.

The Department of Housing and Urban Development (HUD) and the Environmental Protection Agency (EPA) are funding this survey. It is being conducted by QuanTech, a contractor. An interviewer from QuanTech has delivered this letter to your home. If you were not home to receive the letter in person, the Interviewer will stop by again shortly. She or he will show you official ID and ask you some short, easy questions about you and your home. These questions will help see if your home can participate in the survey. For example, vacation homes are excluded from this survey. If your home is eligible, we hope you will participate so that our results will be as complete as possible. Answering the questions is completely voluntary, and you may choose not to answer any question. Your answers, and other data collected in your home, will be kept private to the extent permitted by law. HUD and EPA will use the data only for statistical research and reports.

If you have any questions or if you want to speak to a study representative at any time, please call Dr. David Cox, QuanTech, at 1-800-229-5220. We thank you in advance for your cooperation.

Sincerely,

Warren Friedman

Senior Advisor to the Director

This survey is a Federal program authorized under the Residential Lead-Based Paint Hazard Reduction Act and the National Environmental Policy Act.

OMB No. xxxx-xxxx

expires: mm/dd/2018

|

|||||||

<date>

Dear Sir or Madam:

Recently, an Interviewer stopped by your home concerning the second American Healthy Homes Survey. Because you were not available, I want to tell you a little more about the survey, why we need your participation, and how it will benefit you.

The purpose of the survey is to learn more about exposures in the home environment that may affect the health of families like yours. There is growing evidence that household exposure to substances such as lead (in paint, dust, soil and water), mold, pesticides and formaldehyde can make children and adults ill. The Department of Housing and Urban Development and the Environmental Protection Agency are jointly conducting a nationwide survey to improve our understanding of exposures to these substances in our home environments.

To better understand these exposures, we need to look at all types of homes. Everyone who participates helps to increase our knowledge. Your home was in the first American Healthy Homes Survey (although you may not have lived there then), and we would like to visit it again to see how things have changed in the last 10 years.

As an incentive to participate, you will receive a check for $130 upon completion of the survey in your home, a report on certain chemical and mold exposures, and safety hazards, in your home and, if you choose, a report on lead paint hazards in your home (reports like these can cost hundreds of dollars).

We understand that your life is quite busy but we hope you will find the time to participate in this important study. We want to ask you a few questions about your household, collect some samples of air, water, dust and soil, and measure painted surfaces in your home. We will schedule your participation at your convenience.

Your answers, and other data collected in your home, will be kept private to the extent permitted by law under the Privacy Act of 1974. HUD and EPA will use the data only for statistical research and reports.

If you have any questions about the study, or would like to arrange a specific time for an Interviewer to visit with you, please call Daemian Schreiber, on our survey contract team, at 1-800-229-5220. We thank you in advance for your cooperation with this important health study.

Sincerely,

Warren Friedman

Senior Advisor to the Director

This survey is a Federal program authorized under the Residential Lead-Based Paint Hazard Reduction Act and the National Environmental Policy Act.

OMB No. xxxx-xxxx

expires: mm/dd/2018

|

|||||||

<date>

Dear Sir or Madam:

Recently, an Interviewer stopped by your home concerning the second American Healthy Homes Survey. Because you were not available, I want to tell you a little more about the survey, why we need your participation, and how it will benefit you.

The purpose of the survey is to learn more about how the home environment affects the health of families like yours. There is growing evidence that household exposure to substances such as lead (in paint, dust, soil and water), mold, pesticides and formaldehyde can make children and adults ill. The Department of Housing and Urban Development and the Environmental Protection Agency are jointly conducting a nationwide survey to improve our understanding of exposures to these substances in our home environments.

To better understand these exposures, we need to look at all types of homes. We need your home. Everyone who participates helps to increase our knowledge.

As an incentive to participate, you will receive a check for $130 upon completion of the survey in your home, a report on certain chemical and mold exposures, and safety hazards, in your home and, if you choose, a report on lead paint hazards in your home (reports like these can cost hundreds of dollars).

We understand that your life is quite busy but we hope you will find the time to participate in this important study. We want to ask you a few questions about your household, collect some samples of air, water, dust and soil, and measure painted surfaces in your home. We will schedule your participation at your convenience.

Your answers, and other data collected in your home, will be kept private to the extent permitted by law under the Privacy Act of 1974. HUD and EPA will use the data only for statistical research and reports.

If you have any questions about the study, or would like to arrange a specific time for an Interviewer to visit with you, please call Daemian Schreiber, on our survey contract team, at 1-800-229-5220. We thank you in advance for your cooperation with this important health study.

Sincerely,

Warren Friedman

Senior Advisor to the Director

This survey is a Federal program authorized under the Residential Lead-Based Paint Hazard Reduction Act and the National Environmental Policy Act.

OMB No. xxxx-xxxx

expires: mm/dd/2018

|

|||||||

<date>

Dear Sir or Madam:

Recently, an Interviewer stopped by your home concerning the second American Healthy Homes Survey. I would like to tell you a little more about the survey, and urge you to participate. This is how it will benefit you.

You will receive a report on certain chemical and mold exposures, and safety hazards, in your home and, if you choose, a report on lead paint hazards in your home (reports like these can cost hundreds of dollars).

As an incentive to participate, you will receive a check for $130 upon completion of the survey in your home.

We need to look at all types of homes. We need your home. Whether you have young children living with you or not, everyone who participates helps to increase what we know about exposures to lead, certain chemicals and mold in our home environments. Your home participated in the first American Healthy Homes Survey, although you may not have lived there then. We would like to visit again to see how things have changed in the last 10 years.

Your answers, and other data collected in your home, will be kept private to the extent permitted by law. HUD and EPA will use the data only for statistical research and reports.

If you have any questions about the study, please call Daemian Schreiber, on our survey contract team, at 1-800-229-5220. We thank you in advance for your cooperation with this important health study.

Sincerely,

Warren Friedman

Senior Advisor to the Director

This survey is a Federal program authorized under the Residential Lead-Based Paint Hazard Reduction Act and the National Environmental Policy Act.

OMB No. xxxx-xxxx

expires: mm/dd/2018

|

|||||||

<date>

Dear Sir or Madam:

Recently, an Interviewer stopped by your home concerning the second American Healthy Homes Survey. I would like to tell you a little more about this public health survey, and urge you to participate. This is how it will benefit you.

You will receive a report on certain chemical and mold exposures, and safety hazards, in your home and, if you choose, a report on lead paint hazards in your home (reports like these can cost hundreds of dollars).

As an incentive to participate, you will receive a check for $130 upon completion of the survey in your home.We need to look at all types of homes. We need your home. Whether you have young children living with you or not, everyone who participates helps to increase what we know about exposures to lead, certain chemicals and mold in our home environments.

Your answers, and other data collected in your home, will be kept private to the extent permitted by law under the Privacy Act of 1974. HUD and EPA will use the data only for statistical research and reports.

If you have any questions about the study, please call Daemian Schreiber, on our survey contract team, at 1-800-229-5220. We thank you in advance for your cooperation with this important health study.

Sincerely,

Warren Friedman

Senior Advisor to the Director

This survey is a Federal program authorized under the Residential Lead-Based Paint Hazard Reduction Act and the National Environmental Policy Act.

PSU SUMMARY SHEET |

|||||||||

|

|||||||||

PSU ID |

|

|

|||||||

|

|||||||||

Dwelling units to recruit: |

|||||||||

|

X |

If this box is checked Recruit all DUs with SAMP TYPE = M1, M2, M3, and M4 |

|||||||

|

|||||||||

|

|

If this box is checked, also recruit all DUs with SAMP TYPE = R1 |

|||||||

|

|||||||||

|

|

If this box is checked, also recruit all DUs with SAMP TYPE = R2 |

|||||||

|

|||||||||

Advance Letters to Deliver by Hand |

|||||||||

The following list of DU IDs have unacceptable mailing addresses. Deliver a hand-delivered Advance letter to these DUs if they can be located. |

|||||||||

|

New Advance Letters* |

|

Longitudinal Advance Letters* |

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|||||||||

Other Instructions |

|||||||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|

|

|

|

|||||

|

|||||||||

*Envelopes with: a green dot hold NEW letters; a red dot hold longitudinal letters |

|||||||||

G6-SUMMARY OF TESTING IN EACH DU

Staff Involved: Assigned Interviewer & Field Technician

A summary of the measurements to be conducted in each DU is provided in the Table below

Table G6-1. Estimated Division of Labor for Testing in Each DU |

|||

Onsite Time (Minutes) |

Interviewer |

Technician |

Samples Collected |

1-10 |

I3- Conduct Introduction and obtain Informed Consent |

Participate in Introduction T2- LBP testing - Initiate minimum of 5 minute warm up of XRF. |

Interviewer: 1 drinking water sample (after informed consent) |

11-15

|

I4- Conduct Room Inventory - Select rooms for testing - Pass copy to Technician. - Do quick walk-through with Technician to communicate agreement on the rooms to be tested. -Retrieve First Draw water sample from resident |

T1- Set up and initiate collection of formaldehyde in air sample. T2 - LBP testing - test incoming drinking water service line. |

Technician: 1 formaldehyde sample - collection continues until end of interior onsite activities by the Interviewer |

16-190 |

I5- Administer Resident Questionnaire I6- Conduct Interior Walkthrough observations, collect vacuum bag sample I7-Conduct Room Observation and Building Moisture measurements I8- Collect vacuum dust samples for fungi I9- Collect dust wipe Swiffer™ sample for fungi. I10- Collect flushed water sample |

T2- Conduct LBP testing of interior rooms T3- Collect dust wipe samples for Pb T4- Collect wipe samples for pesticides T1 - Complete collection of formaldehyde in air samples when Interviewer has completed all their indoor activities. |

Interviewer: 0-1 vacuum bag 1 vacuum dust 0-2 dust wipe Swiffer™

Technician: 10 lead dust wipe 2-3 pesticide wipe 0-6 lead soil 1 formaldehyde air |

191-210 |

I11- Conduct Exterior Walkthrough observations – general building condition observations and exterior temperature/humidity measurements. Perform collected sample and data review - store and package samples –conduct closeout with resident |

T5- Collect Soil Samples for Pb T2- Conduct LBP testing of exterior

Perform collected sample and data review - store and package samples –conduct closeout with resident |

Technician: 0-6 lead soil

|

|

(offsite) Perform daily off site activities (sample and data handling) |

|

|

|

(offsite) Perform end-of-PSU activities (equipment, leftover supplies, data and sample shipments) |

|

|

I# and T# numbers above refer to specific written protocols for conduct of the tasks. |

|||

G7 - TELEPHONE VERIFICATION OF DATA COLLECTION |

||

Staff Involved: |

Assigned QT Office Staff |

|

Overview: A random sub-sample (10%) of the completed households will be contacted by telephone to verify the team’s activities and conduct, and to validate selected information from the data forms. Timely verification is needed to ensure that resident responses are not hampered by memory loss. Therefore, these calls will be made on a PSU basis within 2 weeks after completing testing in a PSU. |

||

Data Recording on: |

Telephone Verification Log |

|

Procedure

1. For each PSU that is completed, place the list of the completed DUs ID numbers into an Excel spreadsheet (one per row).

2. Add a random number in an adjacent column next to each DU entry, sort the entire list by the random number, print the list, and label it Telephone Verification QC checklist.

3. Calculate the number of DUs to be checked (10%), round up to the nearest whole number, and highlight the number of DUs to be checked starting from the top of the printed list.

4. For each DU to be checked pull the file containing all the field records for that DU. If the DU selected does not have a resident telephone number, indicate this on the printed list and highlight the next available DU entry in the list as a replacement.

5. For each DU to be checked call the resident and verify the information shown on the Telephone Verification Log:

6. For each discrepancy found, involve the QA officer and conduct an investigation to determine the appropriate actions to be taken.

DU # |

|

Date Recruited: |

|

Date Sampled: |

|

||

Resident name |

|

Telephone No. |

|

||||

Caller Name |

|

Time called: |

|

||||

Caller Name |

|

Time called: |

|

||||

Caller Name |

|

Time called: |

|

||||

Caller Name |

|

Time called: |

|

||||

INTRODUCTION: Hello, my name is (INTERVIEWER NAME). I am with QuanTech, a company that is doing the American Healthy Homes Survey for the United States Department of Housing and Urban Development (HUD) and the United States Environmental Protection Agency (EPA). We are doing a follow up on a recent visit to your house by our field staff and would like to speak to (RESIDENT NAME) to ask a few questions about the survey.

IF THE RESIDENT is not available, try to find out a convenient time to return a call and record below: ______________________________________________________________________________ |

Q1. Do you remember to visit by our Interviewer and Technician?

YES 1

NO 2 (SKIP TO E1)

DON’T KNOW 8 (See Note below)

IF THE RESIDENT does not know, try prompting with the dates. IF the answer is still no, skip to E1 |

Q2. The house our staff visited was your primary residence. Is this correct?

YES 1

NO 2

Q3. Can you verify for us what year was your home/apartment visited by our staff was built?

YEAR OF CONSTRUCTION |___|___|___|___|

DON’T KNOW 8

Q4. Did you find the survey experience helpful or informative?

YES 1

NO 2

Summarize answers here: ____________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

Q5. Do you have any questions regarding the study?

YES 1

NO 2

Summarize questions & answers here: __________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

---------------------------------------------------------------------------------------------------------------------------

E1. Thank you very much for your time and participation.

G8 - ISSUANCE OF PARTICIPANT REPORTS |

||

Staff Involved: |

Assigned QT Office Staff |

|

Overview: Following the completion of data analysis, a participant report is created and mailed to the participant. There are two general types of reports: a Hazards-Found Report and a Hazards-Not-Found Report (see attached examples). Each of these general reports can contain either a Lead Hazards Report section or a Safety Hazards Report section or both (the examples contain both). Participants indicate on the Informed Consent form which of these (lead hazards and/or safety hazards) reports they which to receive and whether or not they opt out of receiving a lead hazards report. If lead hazards are found, the participant will automatically be sent at least the lead hazards portion of the Hazards-Found Report unless they specifically decline to receive the lead hazards report (see the Informed consent form). Assigned statistical staff will create a listing of relevant reporting data (by DU) with a summary of the Informed Consent responses specifying the reports to be sent. Using these listings, reports will be generated and mailed to the participants. |

||

Data Recording on: |

Informed consent tabulations from completed DUs |

|

Examples of reports are provided on the following pages.

<DATE>

<RESPONDENT NAME>

<RESPONDENT ADDRESS>

RE: American Healthy Homes Survey - Results of Lead Testing and Observation of Selected Safety Features

Dear <RESPONDENT NAME>,

Thank you for participating in the American Health Homes Survey, sponsored by the U.S. Department of Housing and Urban Development (HUD) and the U.S. Environmental Protection Agency (EPA). We conducted environmental sampling and a review of safety hazards in your home on <DATE>. You indicated at that time that you would like the results on lead.

Lead Testing Results

We tested several locations in your home for the presence of lead in paint, dust, and soil. We took measurements from these locations in randomly selected areas inside and outside of the home. Some of these tested locations had levels of lead at or above the EPA's standards for lead hazards in homes and childcare facilities. Table 1 gives the lead levels for the sampled surfaces that were found to have lead paint, dust or soil hazards. Please note that during this survey, not all rooms or all surfaces were tested.

Studies have shown that lead levels in paint chips (indicating deteriorated paint in poor condition), house dust or soil at or above the EPA’s standards are hazardous because they present an increased risk that children under six years of age could develop elevated blood lead levels (10 or more micrograms of lead per deciliter of blood). Children in this age range are more susceptible to lead poisoning than are older children or adults. This is because their bones and nervous systems are developing, and, for example, they may crawl and play on the floor or on bare soil where they may be exposed to lead dust, paint chips, or contaminated soil through normal behavior, such as putting their hands and other objects in their mouths. Also, pregnant women can transmit lead to the fetus. If this report shows the presence of deteriorated lead paint, or elevated lead levels in dust or soil, children under the age of 6 and pregnant women should see their health care provider. However, if the only lead found is in intact paint or at lower levels in dust or soil, this is not considered a hazard.

The tests we performed in your home were conducted for purposes of obtaining statistics for the nation, and do not constitute the kind of thorough assessment that you can obtain from an inspection for lead-based paint or from a lead risk assessment by a certified lead-based paint inspector or risk assessor. If you would like additional information about lead in your home, we recommend that you consider having a lead hazard inspection and/or a lead risk assessment performed. You can get a list of certified lead inspectors and risk assessors by contacting your state government

AMERICAN HEALTHY HOMES SURVEY – LEAD HAZARD RESULTS (EXAMPLE) |

|||

<Name> |

|

|

|

<Address> |

|||

MEASUREMENTS AT OR ABOVE EPA STANDARDS

|

|||

Lead at or above EPA Standard in Intact Paint (This is not considered a hazard under the EPA standard.) |

|||

Room Location |

Surface Tested |

Lead Level Found (milligrams of lead per square centimeter of surface) |

EPA Standard for Lead-Based Paint (milligrams of lead per square centimeter of surface) |

Bedroom |

Wall |

1.3 |

1.0 |

Kitchen |

Window |

2.4 |

1.0 |

Exterior North Wall |

Siding |

1.0 |

1.0 |

Lead at or above EPA Standard in Deteriorated Paint (This is considered a hazard under the EPA standard.) |

|||

Room Location |

Surface Tested |

Lead Level Found (milligrams per square centimeter of surface) |

EPA Standard for Lead-Based Paint (milligrams per square centimeter of surface) |

Bedroom |

Wall |

1.4 |

1.0 |

Kitchen |

Trim |

3.0 |

1.0 |

Exterior North Wall |

Door |

1.1 |

1.0 |

Common Living Area |

Trim |

2.6 |

1.0 |

Lead at or above EPA Standard in Interior Surface Dust (This is considered a hazard under the EPA standard.) |

|||

Room Location |

Surface Tested |

Lead Level Found (micrograms of lead per square foot of surface) |

EPA Hazard Standard for Lead in Interior Surface Dust (micrograms of lead per square foot of surface) |

Bedroom |

Floor |

63 |

40 |

Kitchen |

Floor |

127 |

40 |

Other Room |

Window sill |

255 |

250 |

Lead at or above EPA Standard in Bare Soil (This is considered a hazard under the EPA standard.)

Type of area |

Location Info |

Lead Level Found (parts per million by weight) |

EPA Hazard Standard for Lead in Bare Soil in a Play Area (parts per million by weight) |

Foundation/dripline |

West side of Dwelling Unit |

644 |

400 |

HOME SAFETY AUDIT

Fire Extinguisher: A fire extinguisher was not located in the house.

The major causes of most fires are: cooking, heating equipment, and smoking. Fire extinguishers can guard against small fires or keep a small fire from developing into a big one. Because almost all fires are small at first, they might be contained if a fire extinguisher is handy, fully charged, and used properly. The Federal Citizens Information Center (FCIC) has stated that fire extinguishers should be installed on every level of the home, including the kitchen, basement, and garage.

Smoke Alarms: No smoke alarms were found in your home. [OR IF SMOKE ALARMS WERE PRESENT BUT NOT OPERATING PROPERLY: Several smoke alarms were found in your home, however, when tested for operability were found to be not working.]

Residential smoke alarms, when functional, can prevent 50% to 80% of deaths by providing early warning of fires, which often occur at night when people are sleeping. You should follow the manufacturer’s instructions for testing operability and battery replacement if applicable.

Fire Escapes: No observable second fire escape route (either via an additional door or an openable window) was observed from at least one room evaluated.

The U.S. Consumer Product Safety Commission (CPSC) suggests that a family fire escape plan should be practiced every six months. The plan should include at least two different escape routes from each room for each family member. Designate a safe place in front of the house or apartment building for family members to meet after escaping a fire.

Slips, Trips and Falls: Environmental risk factors may contribute to about half of all home falls. Common environmental fall hazards include tripping hazards, lack of stair railings or grab bars, slippery surfaces, unstable furniture, and poor lighting. Most fall injuries in older adults are caused by falls on the same level and from a standing height. Therefore, it makes sense to reduce home hazards and make living areas safer.

No window guards or stops were present on the windows of at least one second story or higher room.

The CPSC has stated that window guards can prevent children from falling out of windows. Guards should be installed in children’s bedrooms, parents’ bedroom, and other rooms where young children spend time. Guards must meet requirements for spacing and strength and those that allow for escape in case of emergencies must be difficult for very young children to open. Consumers can also purchase window stops, which can be added to the window frame to prevent the window from opening more than 4 inches. Some new windows come with window stops already installed.

Area rugs with skid resistant or anti-slip features were not noted in the rooms we examined during our visit.

Tripping hazards can be reduced by using non-slip rug and/or mats, including the bathtub and shower floor.

The stairways were not observed to have at least one hand rail.

Grab bars were not present in the bathroom tub of at least one bathroom.

Grab bars should be placed next to the toilet and in the tub or shower.

Emergency Numbers: No phone had poisoning or emergency numbers posted.

Posting an emergency number such as 911 and a poison control center number such as 1-800-222-1222 near all phones or in a location known to everyone who resides or spends a considerable amount of time in the house provides important information needed during an emergency.

Please call the survey team toll-free at 1-800-229-5220 if you have any questions regarding the findings above. If you are a hearing- or speech-impaired person, you may reach this phone number through TTY by calling the toll-free Federal Information Relay Service at (800) 877-8339.

Sincerely,

Dr. David C. Cox

Project Director

<DATE>

<RESPONDENT NAME>

<RESPONDENT ADDRESS>

RE: American Healthy Homes Survey - Results of Lead Testing and Observation of Selected Safety Features

Dear <RESPONDENT NAME>,

Thank you for participating in the American Health Homes Survey, sponsored by the U.S. Department of Housing and Urban Development (HUD) and the U.S. Environmental Protection Agency (EPA). We conducted environmental sampling and an observation of safety features related to falls, burns and fire hazards in your home on <DATE>. You indicated at that time that you would like the results of lead sampling and observation of selected safety features. These are presented below as they were identified during our visit.

We tested several locations in your home for the presence of lead in paint, dust, and soil. We took measurements from these locations in randomly selected areas inside and outside of the home. The levels of lead in paint, dust, and soil tested were below levels considered to pose a hazard by the EPA standards for lead hazards in homes and childcare facilities. Please note that during this survey not all rooms or building materials were tested. The tests we performed in your home were conducted for purposes of obtaining statistics for the nation, and do not constitute the kind of thorough assessment that you can obtain from an inspection for lead-based paint or from a lead risk assessment by a certified lead-based paint inspector or risk assessor. If you would like additional information about lead in your home, we recommend that you consider having a lead hazard inspection and/or a lead risk assessment performed. You can get a list of certified lead inspectors and risk assessors by contacting your state government.

We made a number of observations regarding safety-related hazards and found no obvious safety hazards.

Please call the survey team toll-free at 1-800-229-5220 if you have any questions regarding the findings above. If you are a hearing- or speech-impaired person, you may reach these phone numbers through TTY by calling the toll-free Federal Information Relay Service at (800) 877-8339.

Sincerely,

Dr. David C. Cox

Project Director

I0/T0- GENERAL PROCEDURES FOR MINIMIZING CONTAMINATION |

|

Staff Involved: |

Assigned Interviewer and Field Technician |

Overview: This protocol provides a general discussion on minimizing inadvertent contamination of the samples collected in the survey. |

|

General Procedures

1. Keep equipment clean. Some of the environmental levels of interest in this survey are extremely low. Because of this, it is very easy to accidentally move measurable amounts of target analytes from one sample to the next and one location to the next. Keeping all tools and sampling supplies as clean as possible will go a long way in combating this problem. Cleaning cloths (wipes) and paper towels are provided as part of the equipment kits for use in helping you keep your equipment and re-useable items clean. Always be sure to clean sampling equipment (templates, etc.) before placing them in a carrying device like a bag, box or bucket prior to each use and keep your carrying device clean by thoroughly cleaning it daily.

2. Organize your equipment and sampling supplies. For each DU, be sure to organize your equipment and supplies so that they can be retrieved with a minimum of handling and without touching other surfaces.

3. Nitrile Glove use. Gloves are used throughout the field collection efforts to accomplish two equally important major objectives. One is to protect collected samples from inadvertent contamination. The other is to protect the user from being contaminated by the materials used to collect sample as well as the sample material itself.

For each field sampling protocol, be sure to think through the various steps to be done before pulling on gloves and only do so when it is prudent. The are some activities, like handling sample labels, that are difficult to do while wearing gloves and you should take care of these, if possible, before donning gloves. In addition, there will likely be other activities other than collecting samples, where you should be wearing gloves so that you avoid cross-contamination issues such as when cleaning sampling templates. Also, it is extremely difficult to pull on nitrile gloves with wet hands so be sure your hands are completely dry before doing so.

For most sample collections, but not all, there are two options with regard to glove use. One is to pull on new gloves to collect the sample. The other is to use existing gloves already being worn and clean them using a cleaning wipe between collections of like-type samples (for example, the same gloves can be used to collect all 6 targeted soil samples as long as you clean them between samples). Whenever gloves are cleaned rather than replaced, be sure to wipe off gloves twice using two cleaning wipes between each pair of samples collected, tossing the used cleaning wipes into the trash. Whenever a protocol is changed to collect a new type of sample, always pull on a new pair of gloves and toss any used gloves currently being worn into the trash. Please note that when collecting pesticide samples (T4), always don a new pair of gloves between the samples collected in a single DU (do not clean them between samples for this target analyte).

4. Clean reusable templates and measuring tools between uses. Always do this cleaning immediately after collecting a sample so that the tools will be dry when needed for the next sample. A paper towel can be used to help dry tools if required for any sample other than formaldehyde. Since paper towels are known to potentially contain a small amount of formaldehyde, they should not be used for cleaning any tools or materials used for this sample collection (T1).

5. Discard cleaning cloths after a single use. Never reuse a cleaning cloth.

6. Clean tools and sampling supplies whenever contamination is suspected.

7. Discard, without use, any cleaning cloth that has been uncovered for more than a few minutes, or that is otherwise suspected of being contaminated.

I2- RECRUITMENT SCREENING |

||||

Staff Involved: |

Assigned Interviewer |

|||

Overview: For each PSU, the Interviewer is sent a Recruiting Supplies - Kit (A) containing an AHHS II Main and reserve sample DU addresses listing. This listing contains information on what dwelling units have been drawn as a sample for potential recruitment in the study. However, not all the DUs in this list are targeted for recruitment. Information on which DUs are to be recruited is summarized in the PSU Summary Sheet. The Interviewer is instructed to contact, screen, and recruit all DUs that are released as directed by the PSU Summary Sheet. Four types of Advance Letters have been created to aid in recruiting: an Advance Letter, an Advance Letter- Hand-Delivered, a No-Contact Letter, and a Refusal Letter. Examples of each are provided in protocol G2. A $1 token cash incentive is included in the official HUD envelope with the Advance Letter.. There are two categories of advance letters: one for longitudinal addresses (those that were included in the AHHS I) and one for new addresses (those not included in AHHS I). QuanTech headquarters (QT) will mail the Advance Letter to each targeted dwelling unit address that has a valid mailing address about one week before the Interviewer arrives in the PSU. An Advance Letter - Hand-Delivered will be dropped off when the Interviewer attempts to recruit the housing unit. DUs including those where there is no proper mailing address as indicated on the PSU Summary Sheet. The Advance Letter - Hand Delivered is used to indicate that an unsuccessful contact visit has been made to a unit. It is left on the doorknob in a clear hanger bag during the first and second attempts. The Interviewer also has one copy of the Advance Letter - Hand Delivered (for longitudinal addresses) and one copy of Advance Letter - Hand Delivered ( for new addresses) flat and sealed in plastic as a reference to the other letters to show to the resident when contact is made. At least four attempts will be made to contact each of the DUs released to the Interviewer, until contact is established. Attempts will made at varying times of the day and on different days of the week. For example, if the first attempt during normal working hours is unsuccessful, the second attempt will be made in the evening. If weekday attempts fail, additional attempts will be made on the weekend. Generally, the first attempted contact will be made during the day, with subsequent contacts made in the evenings and weekends. If four attempts to contact a resident at a selected DU are unsuccessful, the Interviewer should make other attempts when in the area such as when testing other nearby DUs. If this fails to make a contact, the Interviewer will notify QT for further instructions. For DUs that are impossible to reach, e.g., some gated communities and apartment buildings with doormen, the Interviewer will contact QT and QT will send a No Contact Letter by Priority Mail (see letter at end of protocol G2). The No Contact Letter elaborates on the importance of the survey and the incentives for participation and provides a toll-free number to call to schedule a visit. In cases of “hard” refusal, QT will send a Refusal Letter, again by Priority Mail. The Refusal Letter also elaborates on the importance of the survey and the incentives for participation and provides a toll-free number to call to schedule a visit. Depending on the elapsed time between recruitment and testing, the Interviewer will provide the resident a drinking water bottle and go over the instructions with them. Nominally, this bottle should be given to the resident two days before the testing day. If the scheduled testing day is 5 days or more from the day recruiting was completed, the Interviewer is directed to hold off providing the bottle to the resident until the elapsed time between bottle drop-off and testing is between 2-5 days prior to testing. |

||||

Data Recording on: |

Interviewer Form Set pulled from Kit (A) |

|||

Equipment Needed from Kit (A): Take entire kit with you |

||||

|

|

|||

Personally owned items needed and items to be purchased locally as needed: |

||||

|

||||

Items Needed from Drinking Water Shipper - Kit (E) |

||||

|

||||

Glove Use Directives: |

none (see protocol I0) |

|||

PROCEDURE

1. Complete any needed travel planning using the Recruiting Supplies.

2. Pack Auto with Needed Supplies. Gather the items needed for recruiting, as shown at the beginning of this protocol, and securely store them in your automobile. It is generally recommended that you place the entire Recruiting Supplies - Kit (A) into your automobile for use in recruiting.

3. Conduct Recruiting and Safely Store Recruiting Questionnaire Form Set. At each DU, conduct the recruitment screening using the Recruiting Questionnaire Form Sets in Kit (A). Forms are shown at end of this protocol. Use the Scheduling Calendar (loose form) to keep track of the appointment dates for testing. Attempt to make contact and recruit the DU, keeping track of the effort using the Appointment Control Log and In-Person Contact Record that is bound within each Recruiting Questionnaire Form Set (see Note below). At least four attempts must be made to contact each of the DUs released to the Interviewer. Attempts will be made at varying times of the day and on different days of the week. Once contact is made, attempt to recruit the DU using the assigned Recruiting Questionnaire Form Set. For DUs successfully recruited, record the contact information and telephone numbers on the cover page of the Recruiting Questionnaire Form Set. Include the actions listed under step 4 when recruiting:

NOTE: The Interviewer assigns one Recruiting Questionnaire Form Set to each DU when they start to recruit each DU and the Appointment Control Log is bound inside this set. Scheduling Calendars are not bound in the form sets as they are used for tracking all of the DUs being recruited.

4. Using the Recruiting Questionnaire Form Set.

4.1 Use a different form set for each DU released for recruiting. Place the needed form set in the clipboard on top of the Scheduling Calendar for use at a given DU.

4.2 Complete the Cover Sheet. The DU ID, provided to the Interviewer in the PSU Summary Sheet, combines 3 data fields shown on the AHHS II main and reserve sample DU addresses list, and has the following format:

XXX-YYY-ZZ

Where XXX is the PSU ID identifier from the AHHS Main and reserve sample DU addresses list identifier; a number from 101 to 999

YYY is the AHHS SEGID identifier; a number from 001 to 999

ZZ is the SAMP TYPE identifier from the AHHS Main and reserve sample DU addresses list identifier, M1, M2, M3, or M4 for main sample draw and R1 or R2 for reserve sample draw.

4.2.1 Use the Appointment Control Log to keep track of the required 4 recruiting attempts at a DU.

4.2.2 Schedule testing after successful recruiting. Record on the Appointment Reminder Card the scheduled testing day recorded in the Recruiting Questionnaire Form Set (line S8). Hand it to the resident as a reminder of the testing appointment.

4.3 Use a Scheduling Calendar Form to track the DU testing schedule. These forms are provided loose as a tool to keep track of testing schedules for recruited DUs. It is recommended that the Scheduling Calendar Form be kept in Recruiting Supplies Kit (A) on the clipboard so it will always be available at each location as this kit is to travel with the Interviewer at all times while recruiting and testing. Remember that no DUs can be tested until the Technician arrives at the PSU. If you do not know when the technician is to arrive at the PSU, contact QT for that information so you can do your recruiting and scheduling.

4.4 For each DU that is recruited, safely store the completed Recruiting Questionnaire Form Set in the Recruiting Supplies - Kit (A). This form set will be sent back to QT with samples and other data collected during the testing phase of the work. It is recommended that the Recruiting Supplies - Kit (A) be kept with you at all times during both recruiting and testing. When testing for the DU is conducted, the completed Recruiting Questionnaire Form Set is moved from the Recruiting Supplies - Kit (A) to the Sampling Supplies - Kit (B) box used for testing in that DU.

4.5 For each DU that refuses, complete the applicable entries in the refusal/breakoff section of the Recruiting Questionnaire, safely store the completed Recruiting Questionnaire Form Set and other collected data back in the Recruiting Supplies Kit (A), and contact QT with the results no later than the end of the day as described in step (5) below.

4.6 At the door activities:

4.6.1 For 1st visits to the DU

4.6.1.1 If the resident is there, introduce yourself, show them you ID badge and hand them the plastic sealed Advance Letter - Hand Delivered (either longitudinal or new as indicated on the completed PSU Summary Sheet) provided in the Recruiting Supplies Kit (A) and explain to them that a letter like this was sent to them, If they do not remember such, ask them to read it. Then continue on with recruiting as directed in the recruiting questionnaire making sure to retrieve the plastic encased letter as it will be needed at other DUs. If needed, hand them an Advance Letter - Hand Delivered inside an official HUD envelope for them to keep.

4.6.1.2 If the resident is not there, place the Advance Letter - Hand Delivered (either longitudinal or new as indicated on the completed PSU Summary Sheet) on the doorknob of the primary entryway of the DU using a clear plastic doorknob hanger bag.

4.6.2 For 2nd visits to the DU

4.6.2.1 If the resident is there, follow the instructions in step 4.6.1.1 above.

4.6.2.2 If the resident is not there, but the Advance Letter - Hand Delivered has been picked up, place another the Advance Letter - Hand Delivered (either longitudinal or new as indicated on the completed PSU Summary Sheet) on the doorknob of the primary entryway of the DU using a clear plastic doorknob hanger bag.

4.6.3 For 3rd and later visits to the DU

4.5.3.1 If the resident is there, follow instructions in step 4.6.1.1.

4.5.3.2 If the resident is not there, come back at another time. Do NOT leave another Advance Letter - Hand Delivered on 3rd and later visits.

4.6.4 For the LAST visit to the DU

4.6.4.1 If the resident is there, follow instructions in step 4.6.1.1.

4.6.4.2 If the resident is not there, try to get a proper mailing address for the unit (if not known already) and contact QT. QT will send out a No Contact Letter to the address.

4.76 Hard refusals. If the resident refuses to complete the recruitment screening, or refuses the sampling visit after the DU is determined eligible, and conversion efforts fail, contact QT. A Refusal Letter will be sent by Federal Express.

5. Communicate Project Status to QT. Periodically (every other day or so), QT will call the Interviewer to obtain status information. If the Interviewer has not heard from QT in more than 3 days, the Interviewer is asked to call QT and provide a brief verbal report on the recruiting efforts from the previous day, and any other study needs. Note that this call will need to be placed while viewing the information stored in the Recruiting Supplies Kit (A). Items to be communicated include the following:

5.1 DU Recruiting and Testing Info

5.1.1 Which released DUs have been recruited?

5.1.2 Which released DUs were: recruited? Found ineligible? Could not be contacted?, Refused-Why?, Completed-When?

5.1.3 What are the scheduled testing dates for the recruited DUs?

5.1.4 Who will the incentive check be made out to?

5.2 DU Data/Samples Shipped from Field

5.2.1 What FedEx shipments were sent yesterday (record tracking number)?

5.3 DU Data has been transmitted by email from Field

5.3.1 What files were sent since the last verbal report?

5.4 Travel Arrangements

5.4.1 What travel arrangements (airfare, lodging, auto) are needed for Interviewer?

5.4.2 What travel arrangements (airfare, lodging, auto) are needed for Technician?

5.5 Supplies and Other Needs

5.5.1 What additional supplies are needed and by when?

5.5.2 What are the other needs?

Cover Sheet for Recruiting Questionnaire Form Set |

||||||||

|

||||||||

Dwelling Unit ID: |

|

|

|

|

||||

|

PSUID - AHHS SEGID - SAMP TYPE |

|

||||||

DU Address

And

Contact Telephone Numbers (if available) |

|

|

||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

|

|||||||

|

||||||||

Assigned Interviewer |

|

|

||||||

|

||||||||

|

|

Check here if a neighbor was used to the obtain any contact information recorded in this form set and place the name and contact phone number for that neighbor below: |

||||||

|

||||||||

|

|

|

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|

||||||

|

|

|

||||||

|

||||||||

**Note all fields to be completed by Interviewer

Interviewer Name _______________________________ |

PSU ID_____________________ |

||||||||

MINIMUM 4 IN-PERSON ATTEMPTS ON DIFFERENT DAYS AT DIFFERENT TIMES |

|||||||||

RECORD ALL ATTEMPTS/VISITS INCLUDING THE DATA COLLECTION APPOINTMENT VISIT |

|||||||||

RECORD OF CONTACTS |

|||||||||

|

|

Day of |

|

Result |

|

||||

|

Date |

the Week |

Time |

Code |

Comments (Appointment) |

||||

1. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

2. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

3. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

4. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

5. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

6. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

7. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

8. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

9. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

10. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

11. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

12. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

13. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

14. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

15. |

|

|

|

|

|

||||

|

|

|

|

|

|

||||

In-Person Result Codes |

|

|

Telephone Result Codes |

||||||

P1 = No one home |

|

|

T1 = Ring, no answer |

||||||

P2 = Vacant |

|

|

|

T2 = Wrong number |

|||||