NIST Materials Genome Initiative Strategic Planning Study

NIST Generic Clearance for Program Evaluation Data Collections

0693-0033-MaterialsGenomeInitiativeStudy-InterviewGuide-02-24-17

NIST Materials Genome Initiative Strategic Planning Study

OMB: 0693-0033

NIST Materials Genome Initiative Strategic Planning Study: Economic Analysis of National Needs for Technology Infrastructure to Support the Materials Genome Initiative

Interview Guide

The National Institute of Standards and Technology (NIST) in the U.S. Department of Commerce has contracted with RTI International to conduct an economic analysis of standards, measurement, and general purpose technology needs that inhibit efficient development and deployment of advanced materials by U.S. manufacturers.

The objectives of this critical strategic planning study include:

Identify industry needs related to materials innovation infrastructure.

Identify barriers/challenges to meeting these needs.

Estimate the economic impact of meeting these needs.

Review and prioritize public policy and investment options.

Your perspectives will help guide NIST’s strategic planning and program development process. Participation in this analysis is confidential; only aggregated information will be included in any deliverables or communications. Your name and your company’s name will not be disclosed. We do not wish to discuss specific products, strategies, or technologies, but rather your thoughts about industry needs and how investments in technology infrastructure to meet those needs would affect your company and companies like yours.

Our research products will be an economic analysis, final report, and presentation materials. All deliverables will be publicly available in 2018 and these will be shared with you as soon as they are released.

If you have questions, please contact:

Alan O’Connor, Principal Investigator, RTI, 919-541-8841 or oconnor@rti.org

Courtney Silverthorn, NIST Project Officer, NIST, 301-975-4189 or courtney.silverthorn@nist.gov.

This collection of information contains Paperwork Reduction Act (PRA) requirements approved by the Office of Management and Budget (OMB). Notwithstanding any other provisions of the law, no person is required to respond to, nor shall any person be subject to a penalty for failure to comply with, a collection of information subject to the requirements of the PRA unless that collection of information displays a currently valid OMB control number. Public reporting burden for this collection is estimated to be 35 minutes per response, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the data needed and completing and reviewing the collection of information. Send comments regarding this burden estimate or any aspect of this collection of information, including suggestions for reducing this burden, to the National Institute of Standards and Technology, Attn., Courtney Silverthorn, courtney.silverthorn@nist.gov, (301) 975-4189. The OMB Control Number is 0693-0033, with an expiration date of 06/30/2019. |

Respondent Background

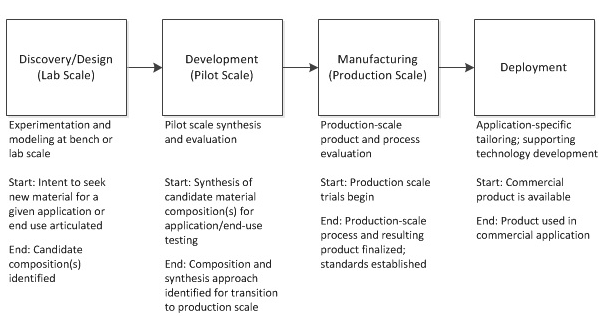

We will be referring to a stylized depiction of the materials innovation process:1

|

Does your perspective cover all four stages, or is it focused within a subset of these stages?

[ ] All stages

[ ] Only the following stages (check all that apply)

[ ] Discovery/Design [ ] Development [ ] Manufacturing [ ] Deployment

Briefly describe the lifecycle of a typical project with which you are involved:

What types of materials does your work involve? (check all that apply)

[ ] Biomaterials [ ] Polymers [ ] Correlated Materials

[ ] Catalysts [ ] Polymer Composites [ ] Electronic and Photonic Materials

[ ] Energy storage [ ] Organic Electronic [ ] Lightweight and Structural

[ ] Photovoltaic [ ] Ceramics [ ] Caloric Materials

[ ] Other ________________________________________

Briefly describe the types of materials and broad applications (we do not need specific information about any proprietary material or product):

Is your background primarily experimental or computational?

[ ] Experimental [ ] Computational [ ] Spans both experimental and computational

Briefly describe the roles of experimental and computational approaches in your work:

Industry Needs Assessment

Table 1 summarizes industry needs identified through scoping interviews.

Please rate the importance to your company of addressing each area of unmet need.

(Please briefly explain the relative importance of meeting these needs.)

Please rate the difficulty for your company of meeting each need on its own, in terms of both the technical difficulty and the business difficulty (i.e., difficulty justifying investment within the business model).

(Please briefly explain the relative difficulty of meeting these needs.)

Are there other needs, of equal or greater importance, not included in Table 1?

(If so, please describe the need, rate its importance and difficulty, and briefly explain.)

Table 1. Industry Needs: Rating Importance and Difficulty

Areas of Industry Need |

Examples of Infrastructure Technology to Address Need |

Importance: 5 = critically 4 = very 3 = moderately 2 = somewhat 1 = not important |

Difficulty: 5 = prohibitively 4 = very 3 = moderately 2 = somewhat 1 = not difficult |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Impacts on Materials Development Process

Given the current environment, please provide generic estimates (i.e., for a typical project) of the relative costs, transition probabilities, and durations of the four stages of materials innovation (Table 2).

How costly is a year of each stage relative to the cost of a year of Discovery/Design? Assume the cost of a year in Discovery/Design is 1.

(For example: A relative cost of 2 at the Development stage would indicate that a year of Development is twice as expensive as a year of Discovery/Design.)

What is the probability that a project that starts a given stage advances to the next stage?

(For example, 0.75 at Development stage implies that a project that starts the Development stage has a 75% chance of advancing to enter the Manufacturing stage.)

About how many years does it take to complete each stage?

How would your answers change in an improved environment where the needs discussed in Section II are addressed? (Table 3).

Note that Relative Cost is not necessarily 1 at the Discovery/Design stage in Table 3. Entering a value of 1 would indicate that the cost per year in the Discovery/Design stage would be unaffected by improvements in infrastructure.

Finally, please describe how changes would come about. How are potential impacts tied to improved infrastructure?

Table 2. Materials Innovation Process in the Current Environment (Existing Technology Infrastructure)

|

Discovery/Design |

Development |

Manufacturing |

Deployment |

(per year) |

1 |

|

|

|

|

|

|

|

N/A |

|

|

|

|

|

Table 3. Materials Innovation Process in the Improved Environment (Improved Technology Infrastructure)

|

Discovery/Design |

Development |

Manufacturing |

Deployment |

(per year) |

|

|

|

|

|

|

|

|

N/A |

|

|

|

|

|

Impacts on New and Improved Products

In addition to the impacts on the development process discussed in Section III, would the improved infrastructure lead to new opportunities to provide value to your customers or reach new markets?

If so, how?

Broadly speaking, would these impacts be more or less important to your company than the R&D impacts discussed in Section III?

Could you quantify the relative importance?

[ ] More important. Enter a number greater than 1: ____________

[ ] Equally important.

[ ] Less important. Enter a number between 0 and 1: ____________

Company Characteristics

To help us aggregate responses and control for differences in company characteristics, please provide the following information for your company:

Industry (NAICS)

[ ] Food (311) [ ] Petroleum and Coal Products (324)

[ ] Chemical (325) [ ] Plastics and Rubber Products (326)

[ ] Primary Metals (331) [ ] Fabricated Metal Product (332)

[ ] Machinery (333) [ ] Computer and Electronic Product (334)

[ ] Electrical Equipment, Appliance, and Component (335)

[ ] Transportation Equipment (336)

[ ] Miscellaneous, incl. medical equipment and supplies (339)

Company Size (Total Number of Employees)

[ ] less than 50

[ ] 50–99

[ ] 100–249

[ ] 250–499

[ ] 500–999

[ ] 1,000–4,999

[ ] 5,000–9,999

[ ] 10,000–24,999

[ ] 25,000 or more

Company Characteristics Continued

R&D Size (Total Number of R&D Employees)

[ ] less than 5

[ ] 5–9

[ ] 10–24

[ ] 25–49

[ ] 50–99

[ ] 100–499

[ ] 500–999

[ ] 1,000–2,499

[ ] 2,500 or more

What percentage of your company’s R&D effort is related to developing and applying advanced materials?

0% to 20%

20% to 40%

40% to 60%

60% to 80%

80% to 100%

[ ]

[ ]

[ ]

[ ]

[ ]

On average, for companies in your industry, roughly what percentage of R&D effort do you think is related to developing and applying advanced materials?

0% to 20% |

20% to 40% |

40% to 60% |

60% to 80% |

80% to 100% |

[ ] |

[ ] |

[ ] |

[ ] |

[ ] |

Concluding Thoughts

Is there anything else that we have not covered that you think is important for us to know?

Is there anyone else that you would recommend we reach out to for our analysis?

Many thanks for your input!

1 Based on Quantitative Benchmark for Time to Market (QBTM) for New Materials Innovation: An Analytical Framework. mgi.nist.gov/sites/default/files/uploads/user124/QBTM%20Final%20Analytical%20Framework_011216.pdf.

| File Type | application/vnd.openxmlformats-officedocument.wordprocessingml.document |

| Author | Walsh, Amanda |

| File Modified | 0000-00-00 |

| File Created | 2021-01-22 |

© 2026 OMB.report | Privacy Policy