|

|

Title

29: Labor

PART

1917—MARINE TERMINALS

Authority:

33 U.S.C. 941; 29 U.S.C. 653, 655, 657; Secretary of Labor's

Order No. 12-71 (36 FR 8754), 8-76 (41 FR 25059), 9-83 (48 FR

35736), 1-90 (55 FR 9033), 6-96 (62 FR 111), 3-2000 (65 FR

50017), 5-2002 (67 FR 65008), 5-2007 (72 FR 31160), 4-2010 (75

FR 55355), or 1-2012 (77 FR 3912), as applicable; and 29 CFR

part 1911

Section

1917.28 also issued under 5 U.S.C. 553.

Section

1917.29 also issued under 49 U.S.C. 1801-1819 and 5 U.S.C.

553.

Source:

48 FR 30909, July 5, 1983, unless otherwise noted.

Back

to Top

Back

to Top

Subpart

A—General Provisions

Back

to Top

Back

to Top

§1917.1 Scope

and applicability.

(a)

The regulations of this part apply to employment within a

marine terminal as defined in §1917.2, including the

loading, unloading, movement or other handling of cargo,

ship's stores or gear within the terminal or into or out of

any land carrier, holding or consolidation area, any other

activity within and associated with the overall operation and

functions of the terminal, such as the use and routine

maintenance of facilities and equipment. All cargo transfer

accomplished with the use of shore-based material handling

devices shall be regulated by this part.

(1)

The provisions of this part 1917 do not apply to the

following:

(i)

Facilities used solely for the bulk storage, handling and

transfer of flammable, non-flammable and combustible liquids

and gases.

(ii)

Facilities subject to the regulations of the Office of

Pipeline Safety Regulation of the Materials Transportation

Bureau, Department of Transportation, to the extent such

regulations apply.

(iii)

Fully automated bulk coal handling facilities contiguous to

electrical power generating plants.

(2)

Part 1910 of this chapter does not apply to marine terminals

except for the following provisions:

(i)

Abrasive

blasting.

Subpart G, §1910.94(a);

(ii)

Access

to employee exposure and medical records.

Subpart Z, §1910.1020;

(iii)

Commercial

diving operations.

Subpart T of part 1910;

(iv)

Electrical.

Subpart S of part 1910;

(v)

Grain

handling facilities.

Subpart R, §1910.272;

(vi)

Hazard

communication.

Subpart Z, §1910.1200;

(vii)

Ionizing

radiation.

Subpart Z, §1910.1096;

(viii)

Noise.

Subpart G, §1910.95;

(ix)

Nonionizing

radiation.

Subpart G, §1910.97;

(x)

Respiratory

protection.

Subpart I, §1910.134;

(xi)

Safety

requirements for scaffolding.

Subpart D, §1910.28;

(xii)

Servicing

multi-piece and single piece rim wheels.

Subpart N, §1910.177;

(xiii)

Toxic

and hazardous substances.

Subpart Z applies to marine cargo handling activities except

for the following:

(A)

When a substance or cargo is contained within a sealed, intact

means of packaging or containment complying with Department of

Transportation or International Maritime Organization

requirements;1

1The

International Maritime Organization publishes the

International Maritime Dangerous Goods Code to aid compliance

with the international legal requirements of the International

Convention for the Safety of Life at Sea, 1960.

(B)

Bloodborne pathogens, §1910.1030;

(C)

Carbon monoxide, §1910.1000 (See §1917.24(a)); and

(D)

Hydrogen sulfide, §1910.1000 (See §1917.73(a)(2));

and

(E)

Hexavalent chromium §1910.1026 (See §1915.1026)

(xiv)

Powered industrial truck operator training, Subpart N,

§1910.178(1).

Note

to paragraph (a)(2)(xiv):

The compliance dates of December 1, 1999 set forth in 29 CFR

1910.178(l)(7) are stayed until March 1, 2000 for Marine

Terminals.

(b)

Section 1915.1026 applies to any occupational exposures to

hexavalent chromium in workplaces covered by this part.

[48

FR 30909, July 5, 1983, as amended at 52 FR 36026, Sept. 25,

1987; 52 FR 49624, Dec. 31, 1987; 62 FR 40196, July 25, 1997;

63 FR 66274, Dec. 1, 1998; 64 FR 46847, Aug. 27, 1999; 65 FR

40938, June 30, 2000; 71 FR 10381, Feb. 28, 2006]

Back

to Top

Back

to Top

§1917.2 Definitions.

Apron

means that open portion of a marine terminal immediately

adjacent to a vessel berth and used in the direct transfer of

cargo between the terminal and vessel.

Authorized,

in reference to an employee's assignment, means selected by

the employer for that purpose.

Cargo

door

(transit shed door) means a door designed to permit transfer

of cargo to and from a marine terminal structure.

Cargo

packaging

means any method of containment for shipment, including cases,

cartons, crates and sacks, but excluding large units such as

intermodal containers, vans or similar devices.

Confined

space

means:

(1)

A space having all of the following characteristics:

(i)

Small size;

(ii)

Severely limited natural ventilation;

(iii)

Capability to accumulate or contain a hazardous atmosphere;

(iv)

Exits that are not readily accessible; and

(v)

A design not meant for continuous human occupancy.

(2)

Examples of confined spaces are intermodal tank containers,

bailwater tanks and portable tanks.

Conveyor

means a device designed exclusively for transporting bulk

materials, packages or objects in a predetermined path and

having fixed or selective points of loading or discharge.

Danger

zone

means any place in or about a machine or piece of equipment

where an employee may be struck by or caught between moving

parts, caught between moving and stationary objects or parts

of the machine, caught between the material and a moving part

of the machine, burned by hot surfaces or exposed to electric

shock. Examples of danger zones are nip and shear points,

shear lines, drive mechanisms, and areas beneath

counterweights.

Designated

person

means a person who possesses specialized abilities in a

specific area and is assigned by the employer to perform a

specific task in that area.

Dock

means a wharf or pier forming all or part of a waterfront

facility, including marginal or quayside berthing facilities;

not to be confused with “loading dock” as at a

transit shed or container freight station, or with the body of

water between piers or wharves.

Dockboards

(car and bridge plates) mean devices for spanning short

distances between rail cars or highway vehicles and loading

platforms that do not expose employees to falls greater than 4

feet (1.22 m).

Enclosed

space

means an indoor space, other than a confined space, that may

contain or accumulate a hazardous atmosphere due to inadequate

natural ventilation. Examples of enclosed spaces are trailers,

railcars, and storage rooms.

Examination,

as applied to material handling devices required by this part

to be certificated, means a comprehensive survey consisting of

the criteria outlined in 29 CFR 1919.71(d) as applicable to

the type of gear or device. The examination is supplemented by

a unit proof test in the case of a quadrennial survey.

Flammable

atmosphere

means an atmosphere containing more than 10 percent of the

lower flammable limit of a flammable or combustible vapor or

dust mixed with air.

Front-end

attachments.

(1) As applied to power-operated industrial trucks, means the

various devices, such as roll clamps, rotating and

sideshifting carriages, magnets, rams, crane arms or booms,

load stabilizers, scoops, buckets and dumping bins, attached

to the load end for handling lifts as single or multiple

units.

(2)

As applied to cranes, means various attachments applied to the

basic machine for the performance of functions such as

lifting, clamshell or magnet services.

Fumigant

is a substance or mixture of substances, used to kill pests or

prevent infestation, which is a gas or is rapidly or

progressively transformed to the gaseous state, even though

some nongaseous or particulate matter may remain and be

dispersed in the treatment space.

Hazardous

cargo, material, substance or atmosphere

means:

(1)

Any substance listed in 29 CFR part 1910, subpart Z;

(2)

Any material in the Hazardous Materials Table and Hazardous

Materials Communications Regulations of the Department of

Transportation, 49 CFR part 172;

(3)

Any article not properly described by a name in the Hazardous

Materials Table and Hazardous Materials Communications

Regulations of the Department of Transportation, 49 CFR part

172 but which is properly classified under the definition of

those categories of dangerous articles given in 49 CFR Part

173; or

(4)

Any atmosphere with an oxygen content of less than 19.5%.

House

falls

means spans and supporting members, winches, blocks, and

standing and running rigging forming part of a marine terminal

and used with a vessel's cargo gear to load or unload by means

of married falls.

Inspection,

as applied to material handling devices required by this part

to be certificated, means a complete visual examination of all

visible parts of the device.

Intermodal

container

means a reusable cargo container of a rigid construction and

rectangular configuration; fitted with devices permitting its

ready handling, particularly its transfer from one mode of

transport to another; so designed to be readily filled and

emptied; intended to contain one or more articles of cargo or

bulk commodities for transportation by water and one or more

other transport modes. The term includes completely enclosed

units, open top units, fractional height units, units

incorporating liquid or gas tanks and other variations fitting

into the container system. It does not include cylinders,

drums, crates, cases, cartons, packages, sacks, unitized loads

or any other form of packaging.

Loose

gear

means removable and replaceable components of equipment or

devices which may be used with or as a part of assembled

material handling units for purposes such as making

connections, changing line direction and multiplying

mechanical advantage. Examples are shackles and snatch blocks.

Marine

terminal

means wharves, bulkheads, quays, piers, docks and other

berthing locations and adjacent storage or adjacent areas and

structures associated with the primary movement of cargo or

materials from vessel to shore or shore to vessel including

structures which are devoted to receiving, handling, holding,

consolidating and loading or delivery of waterborne shipments

or passengers, including areas devoted to the maintenance of

the terminal or equipment. The term does not include

production or manufacturing areas nor does the term include

storage facilities directly associated with those production

or manufacturing areas.

Ramps

mean other flat-surface devices for passage between levels and

across openings not covered under “dockboards.”

Ship's

stores

means materials that are aboard a vessel for the upkeep,

maintenance, safety, operation, or navigation of the vessel,

or for the safety or comfort of the vessel's passengers or

crew.

[48

FR 30909, July 5, 1983, as amended at 62 FR 40196, July 25,

1997; 65 FR 40938, June 30, 2000; 76 FR 33610, June 8, 2011]

Back

to Top

Back

to Top

§1917.3 Incorporation

by reference.

(a)

(1) The standards of agencies of the U.S. Government, and

organizations which are not agencies of the U.S. Government

which are incorporated by reference in this part, have the

same force and effect as other standards in this part. Only

the mandatory provisions (i.e. provisions containing the word

“shall” or other mandatory language) of standards

incorporated by reference are adopted as standards under the

Occupational Safety and Health Act.

(2)

The standards listed in paragraph (b) of this section are

incorporated by reference in the corresponding sections noted

as the sections exist on the date of the approval, and a

notice of any change in these standards will be published in

the Federal

Register.

The Director of the Federal Register approved these

incorporations by reference in accordance with 5 U.S.C. 552(a)

and 1 CFR part 51.

(3)

Any changes in the standards incorporated by reference in this

part and an official historic file of such changes are

available for inspection in the Docket Office at the national

office of the Occupational Safety and Health Administration,

U.S. Department of Labor, Washington, DC 20910; telephone:

202-693-2350 (TTY number: 877-889-5627).

(4)

Copies of standards listed in this section and issued by

private standards organizations are available for purchase

from the issuing organizations at the addresses or through the

other contact information listed below for these private

standards organizations. In addition, these standards are

available for inspection at the National Archives and Records

Administration (NARA). For information on the availability of

this material at NARA, telephone: 202-741-6030, or go to

http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html.

Also, the material is available for inspection at any Regional

Office of the Occupational Safety and Health Administration

(OSHA), or at the OSHA Docket Office, U.S. Department of

Labor, 200 Constitution Avenue, NW., Room N-2625, Washington,

DC 20210; telephone: 202-693-2350 (TTY number: 877-889-5627).

(b)

Except as noted, copies of the standards listed below in this

paragraph are available for purchase from the American

National Standards Institute (ANSI), 25 West 43rd Street, 4th

Floor, New York, NY 10036; telephone: 212-642-4900; fax:

212-398-0023; Web site: http://www.ansi.org.

(1)

ANSI A14.1-1990, Safety Requirements for Portable Wood

Ladders; IBR approved for §1917.119(c).

(2)

ANSI A14.2-1990, Safety Requirements for Portable Metal

Ladders; IBR approved for §1917.119(c).

(3)

ANSI A14.5-1992, Safety Requirements for Portable Reinforced

Plastic Ladders; IBR approved for §1917.119(c).

(4)

ANSI Z41-1999, American National Standard for Personal

Protection—Protective Footwear; IBR approved for

§1917.94(b)(1)(ii). Copies of ANSI Z41-1999 are available

for purchase only from the National Safety Council, P.O. Box

558, Itasca, IL 60143-0558; telephone: 1-800-621-7619; fax:

708-285-0797; Web site: http://www.nsc.org.

(5)

ANSI Z41-1991, American National Standard for Personal

Protection—Protective Footwear; IBR approved for

§1917.94(b)(1)(iii). Copies of ANSI Z41-1991 are

available for purchase only from the National Safety Council,

P.O. Box 558, Itasca, IL 60143-0558; telephone:

1-800-621-7619; fax: 708-285-0797; Web site:

http://www.nsc.org.

(6)

ANSI Z87.1-2003, American National Standard Practice for

Occupational and Educational Eye and Face Protection; IBR

approved for §1917.91(a)(1)(i)(A). Copies of ANSI

Z87.1-2003 are available for purchase only from the American

Society of Safety Engineers, 1800 East Oakton Street, Des

Plaines, IL 60018-2187; telephone: 847-699-2929; or from the

International Safety Equipment Association (ISEA), 1901 North

Moore Street, Arlington, VA 22209-1762; telephone:

703-525-1695; fax: 703-528-2148; Web site:

http://www.safetyequipment.org.

(7)

ANSI Z87.1-1989 (R-1998), American National Standard Practice

for Occupational and Educational Eye and Face Protection; IBR

approved for §1917.91(a)(1)(i)(B). Copies of ANSI

Z87.1-1989 (R-1998) are available for purchase only from the

American Society of Safety Engineers, 1800 East Oakton Street,

Des Plaines, IL 60018-2187; telephone: 847-699-2929.

(8)

ANSI Z87.1-1989, American National Standard Practice for

Occupational and Educational Eye and Face Protection; IBR

approved for §1917.91(a)(1)(i)(C). Copies of ANSI

Z87.1-1989 are available for purchase only from the American

Society of Safety Engineers, 1800 East Oakton Street, Des

Plaines, IL 60018-2187; telephone: 847-699-2929.

(9)

American National Standards Institute (ANSI) Z89.1-2009,

American National Standard for Industrial Head Protection,

approved January 26, 2009; IBR approved for §1917.93(b)(1)(i).

Copies of ANSI Z89.1-2009 are available for purchase only from

the International Safety Equipment Association, 1901 North

Moore Street, Arlington, VA 22209-1762; telephone:

703-525-1695; fax: 703-528-2148; Web site:

www.safetyequipment.org.

(10)

American National Standards Institute (ANSI) Z89.1-2003,

American National Standard for Industrial Head Protection; IBR

approved for §1917.93(b)(1)(ii). Copies of ANSI

Z89.1-2003 are available for purchase only from the

International Safety Equipment Association, 1901 North Moore

Street, Arlington, VA 22209-1762; telephone: 703-525-1695;

fax: 703-528-2148; Web site: www.safetyequipment.org.

(11)

American National Standards Institute (ANSI) Z89.1-1997,

American National Standard for Personnel Protection—Protective

Headwear for Industrial Workers—Requirements; IBR

approved for §1917.93(b)(1)(iii). Copies of ANSI

Z89.1-1997 are available for purchase only from the

International Safety Equipment Association, 1901 North Moore

Street, Arlington, VA 22209-1762; telephone: 703-525-1695;

fax: 703-528-2148; Web site: www.safetyequipment.org.

(12)

ASME B56.1, 1959, Safety Code for Powered Industrial Trucks,

pages 8 and 13; IBR approved for §1917.50(j)(1).

(c)

Copies of the following standards are available for purchase

from ASTM International, 100 Barr Harbor Drive, P.O. Box C700,

West Conshohocken, PA 19428-2959; telephone: 610-832-9585;

fax: 610-832-9555; e-mail: seviceastm.org;

Web site: http://www.astm.org:

(1)

ASTM F-2412-2005, Standard Test Methods for Foot Protection;

IBR approved for §1917.94(b)(1)(i).

(2)

ASTM F-2413-2005, Standard Specification for Performance

Requirements for Protective Footwear; IBR approved for

§1917.94(b)(1)(i).

[62

FR 40196, July 25, 1997, as amended at 65 FR 40938, June 30,

2000; 69 FR 18803, Apr. 9, 2004; 74 FR 46358, Sept. 9, 2009;

77 FR 37599, June 22, 2012]

Back

to Top

Back

to Top

§1917.4 OMB

control numbers under the Paperwork Reduction Act.

The

following list identifies the 29 CFR citations for sections or

paragraphs in this part that contain a collection of

information requirement approved by the Office of Management

and Budget (OMB). The list also provides the control number

assigned by OMB to each approved requirement; control number

1218-0196 expires on May 31, 2002 and control number 1218-0003

expires on July 31, 2001. The list follows:

29

CFR citation

|

OMB

control number.

|

1917.17(n)

|

1218-0196

|

1917.17(o)

|

1218-0196

|

1917.23(b)(1)

|

1218-0196

|

1917.23(b)(2)

|

1218-0196

|

1917.23(d)(4)

|

1218-0196

|

1917.24(b)

|

1218-0196

|

1917.24(d)

|

1218-0196

|

1917.25(a)

|

1218-0196

|

1917.25(b)

|

1218-0196

|

1917.25(c)

|

1218-0196

|

1917.25(f)

|

1218-0196

|

1917.26(d)(7)

|

1218-0196

|

1917.30(a)(1)

|

1218-0196

|

1917.30(a)(5)(iii)

|

1218-0196

|

1917.42(b)(1)

|

1218-0196

|

1917.42(b)(4)

|

1218-0196

|

1917.42(c)(1)

|

1218-0196

|

1917.42(d)(1)

|

1218-0196

|

1917.42(g)(3)

|

1218-0003

|

1917.42(h)(1)

|

1218-0196

|

1917.42(h)(4)

|

1218-0003

|

1917.42(h)(5)

|

1218-0196

|

1917.44(e)

|

1218-0196

|

1917.44(h)

|

1218-0196

|

1917.45(f)(1)(i)

|

1218-0196

|

1917.45(f)(4)(iv)

|

1218-0196

|

1917.45(f)(6)

|

1218-0196

|

1917.45(g)(2)

|

1218-0196

|

1917.45(g)(3)(iii)

|

1218-0196

|

1917.45(g)(8)

|

1218-0196

|

1917.45(k)(1)

|

1218-0196

|

1917.45(k)(4)

|

1218-0196

|

1917.46(a)(1)(v)

|

1218-0196

|

1917.50(c)(1)

|

1218-0003

|

1917.50(c)(3)

|

1218-0003

|

1917.50(c)(4)(i)

|

1218-0003

|

1917.50(c)(5)(ii)

|

1218-0003

|

1917.50(c)(5)(iii)

|

1218-0003

|

1917.50(e)

|

1218-0003

|

1917.50(g)(1)

|

1218-0003

|

1917.50(h)

|

1218-0003

|

1917.71(a)

|

1218-0196

|

1917.71(b)(2)(i)

|

1218-0196

|

1917.71(b)(2)(ii)

|

1218-0196

|

1917.71(b)(6)(ii)

|

1218-0196

|

1917.71(f)(4)

|

1218-0196

|

1917.111(b)

|

1218-0196

|

1917.113

|

1218-0196

|

1917.115(c)

|

1218-0196

|

1917.116(e)

|

1218-0196

|

1917.116(g)

|

1218-0196

|

1917.117(a)

|

1218-0196

|

1917.117(b)

|

1218-0196

|

1917.117(d)

|

1218-0196

|

1917.117(e)

|

1218-0196

|

1917.117(f)

|

1218-0196

|

1917.117(l)

|

1218-0196

|

1917.118(e)(4)(i)

|

1218-0196

|

1917.119(e)

|

1218-0196

|

1917.122(a)

|

1218-0196

|

1917.122(b)

|

1218-0196

|

1917.128(b)(1)-(b)(4)

|

1218-0196

|

1917.151(e)(5)

|

1218-0196

|

1917.152(d)(2)(v)

|

1218-0196

|

1917.152(d)(2)(vi)

|

1218-0196

|

[64

FR 61505, Nov. 12, 1999]

Back

to Top

Back

to Top

§1917.5 Compliance

duties owed to each employee.

(a)

Personal

protective equipment.

Standards in this part requiring the employer to provide

personal protective equipment (PPE), including respirators and

other types of PPE, because of hazards to employees impose a

separate compliance duty with respect to each employee covered

by the requirement. The employer must provide PPE to each

employee required to use the PPE, and each failure to provide

PPE to an employee may be considered a separate violation.

(b)

Training.

Standards in this part requiring training on hazards and

related matters, such as standards requiring that employees

receive training or that the employer train employees, provide

training to employees, or institute or implement a training

program, impose a separate compliance duty with respect to

each employee covered by the requirement. The employer must

train each affected employee in the manner required by the

standard, and each failure to train an employee may be

considered a separate violation.

[73

FR 75587, Dec. 12, 2008]

Back

to Top

Back

to Top

Subpart

B—Marine Terminal Operations

Back

to Top

Back

to Top

§1917.11 Housekeeping.

(a)

Active work areas shall be kept free of equipment and

materials not in use, and clear of debris, projecting nails,

strapping and other sharp objects not necessary for the work

in progress.

(b)

Hatch beams, covers and pontoons placed in terminal working

areas shall be stowed in stable piles with beams secured

against tipping or falling. Alternatively, beams may be laid

on their sides. When beams and pontoons are stowed in tiers

more than one high, dunnage or other suitable material shall

be used under and between tiers.

(c)

Cargo and material shall not obstruct access to vessels,

cranes, vehicles or buildings. Means of access and egress

within buildings shall be similarly unobstructed.

(d)

Dunnage, lumber, or shoring material in which there are

visibly protruding nails shall be removed from the immediate

work area or if left in the area, the nails shall be rendered

harmless.

[48

FR 30909, July 5, 1983, as amended at 62 FR 40196, July 25,

1997]

Back

to Top

Back

to Top

§1917.12 Slippery

conditions.

The

employer shall eliminate, to the extent possible, conditions

causing slippery working and walking surfaces in immediate

work areas used by employees.

Back

to Top

Back

to Top

§1917.13 Slinging.

(a)

Drafts shall be safely slung before being hoisted. Loose

dunnage or debris hanging or protruding from loads shall be

removed.

(b)

Bales of cotton, wool, cork, wood pulp, gunny bags or similar

articles shall be hoisted only by straps strong enough to

support the weight of the bale. At least two hooks, each in a

separate strap, shall be used.

(c)

Unitized loads bound by bands or straps may be hoisted by the

banding or strapping only if the banding or strapping is

suitable for hoisting and is strong enough to support the

weight of the load.

(d)

Additional means of hoisting shall be employed to ensure safe

lifting of unitized loads having damaged banding or strapping.

(e)

Case hooks shall be used only with cases designed to be

hoisted by these hooks.

(f)

Loads requiring continuous manual guidance during handling

shall be guided by guide ropes (tag lines) that are long

enough to control the load.

(g)

Intermodal containers shall be handled in accordance with

§1917.71(f).

(h)

The employer shall require employees to stay clear of the area

beneath overhead drafts or descending lifting gear.

(i)

Employees shall not be permitted to ride the hook or the load.

[48

FR 30909, July 5, 1983, as amended at 62 FR 40197, July 25,

1997]

Back

to Top

Back

to Top

§1917.14 Stacking

of cargo and pallets.

Cargo,

pallets and other material stored in tiers shall be stacked in

such a manner as to provide stability against sliding and

collapse.

Back

to Top

Back

to Top

§1917.15 Coopering.

Repair

and reconditioning of damaged or leaking cargo packaging

(coopering) shall be performed so as not to endanger

employees.

Back

to Top

Back

to Top

§1917.16 Line

handling. (See also §1917.95(b)).

(a)

In order to provide safe access for handling lines while

mooring and unmooring vessels, cargo or material shall not be

stowed or vehicles placed where they obstruct the work surface

to be used.

(b)

When stringpiece or apron width is insufficient for safe

footing, grab lines or rails shall be installed on the sides

of permanent structures. (“Stringpiece” means a

narrow walkway between the water edge of a berth and a shed or

other structure.)

Back

to Top

Back

to Top

§1917.17 Railroad

facilities.

(a)

Work shall be performed in railcars only if floors of the

railcars are in visibly safe condition for the work activity

being conducted and equipment being used.

(b)

A route shall be established to allow employees to pass to and

from places of employment without passing under, over or

through railcars, or between cars less than 10 feet (3 m)

apart on the same track.

(c)

The employer shall direct that no employees remain in railcars

after work is concluded.

(d)

Railcars shall be chocked or otherwise prevented from moving:

(1)

While dockboards or carplates are in position; or

(2)

While employees are working within, on or under the railcars

or near the tracks at the ends of the cars.

(e)

When employees are working in, on, or under a railcar,

positive means shall be taken to protect them from exposure to

impact from moving railcars.

(f)

Before cars are moved, unsecured and overhanging stakes, wire

straps, banding and similar objects shall be removed or placed

so as not to create hazards.

(g)

The employer shall institute all necessary controls during

railcar movement to safeguard personnel. If winches or

capstans are employed for movement, employees shall stand

clear of the hauling rope and shall not stand between the rope

and the cars.

(h)

Before being opened fully, doors shall be opened slightly to

ensure that the load has not shifted during transit. Special

precautions shall be taken if the doors being opened are

visibly damaged.

(i)

If powered industrial trucks are used to open railcar doors,

the trucks or the railcar doors shall be equipped with door

opening attachments. Employees shall stand clear of the

railcar doors while they are being opened and closed.

(j)

Only railcar door openers or powered industrial trucks

equipped with door opening attachments shall be used to open

jammed doors.

(k)

Employees shall not remain in or on gondolas or flat cars when

drafts that create overhead, caught-in, caught-between or

struck-by hazards are being landed in or on the railcar; end

gates, if raised, shall be secured.

(l)

Operators of railcar dumps shall have an unrestricted view of

dumping operations and shall have emergency means of stopping

movement.

(m)

Recessed railroad switches shall be enclosed to provide a

level surface.

(n)

Warning signs shall be posted where doorways open onto tracks,

at blind corners and at similar places where vision may be

restricted.

(o)

Warning signs shall be posted if insufficient clearance for

personnel exists between railcars and structures.

[48

FR 30909, July 5, 1983, as amended at 62 FR 40197, July 25,

1997]

Back

to Top

Back

to Top

§1917.18 Log

handling.

(a)

The employer shall ensure that structures (bunks) used to

contain logs have rounded corners and rounded structural parts

to avoid sling damage.

(b)

Two or more binders or equivalently safe means of containment

shall remain on logging trucks and railcars to secure logs

during movement of the truck or car within the terminal.

During unloading, logs shall be prevented from moving while

binders are being removed.

(c)

Logs shall be hoisted by two slings or by other gear designed

for safe hoisting.

(d)

Logs placed adjacent to vehicle curbs on the dock shall not be

over one tier high unless placed in bunks or so stacked as not

to roll or otherwise create a hazard to employees.

(e)

Before logs are slung up from the dock, they shall be stably

supported to prevent spreading and to allow passage of slings

beneath the load. When bunks or similar retaining devices are

used, no log shall be higher than the stanchions or retaining

members of the device.

Back

to Top

Back

to Top

§1917.19 Movement

of barges and railcars.

Barges

and railcars shall not be moved by cargo runners (running

rigging) from vessel cargo booms, cranes or other equipment

not suitable for the purpose.

Back

to Top

Back

to Top

§1917.20 Interference

with communications.

Cargo

handling operations shall not be carried on when

noise-producing, maintenance, construction or repair work

interferes with the communication of warnings or instructions.

[62

FR 40197, July 25, 1997]

Back

to Top

Back

to Top

§1917.21 Open

fires.

Open

fires and fires in drums or similar containers are prohibited.

Back

to Top

Back

to Top

§1917.22 Hazardous

cargo2

(See §1917.2(p)).

2The

Department of Transportation and the United States Coast Guard

apply requirements related to handling, storing and

transportation of hazardous cargo (see 33 CFR part 126, 46

CFR, 49 CFR).

(a)

Before cargo handling operations begin, the employer shall

ascertain whether any hazardous cargo is to be handled and

shall determine the nature of the hazard. The employer shall

inform employees of the nature of any hazard and any special

precautions to be taken to prevent employee exposure, and

shall instruct employees to notify him of any leaks or spills.

(b)

All hazardous cargo shall be slung and secured so that neither

the draft nor individual packages can fall as a result of

tipping the draft or slacking of the supporting gear.

(c)

If hazardous cargo is spilled or if its packaging leaks,

employees shall be removed from the affected area until the

employer has ascertained the specific hazards, provided any

equipment, clothing and ventilation and fire protection

equipment necessary to eliminate or protect against the

hazard, and has instructed cleanup employees in a safe method

of cleaning up and disposing of a spill and handling and

disposing of leaking containers. Actual cleanup or disposal

work shall be conducted under the supervision of a designated

person.

Back

to Top

Back

to Top

§1917.23 Hazardous

atmospheres and substances (see also §1917.2 Hazardous

cargo, material, substance or atmosphere).

(a)

Purpose

and scope.

This section covers areas in which the employer is aware that

a hazardous atmosphere or substance may exist, except where

one or more of the following sections apply: §1917.22

Hazardous cargo; §1917.24 Carbon monoxide; §1917.25

Fumigants, pesticides, insecticides and hazardous

preservatives; §1917.73 Terminal facilities handling

menhaden and similar species of fish; §1917.152 Welding,

cutting, and heating (hot work); and §1917.153 Spray

painting.

(b)

Determination

of hazard.

(1) When the employer is aware that a room, building, vehicle,

railcar, or other space contains or has contained a hazardous

atmosphere, a designated and appropriately equipped person

shall test the atmosphere before employee entry to determine

whether a hazardous atmosphere exists.

(2)

Records of results of any tests required by this section shall

be maintained for at least thirty (30) days.

(c)

Testing

during ventilation.

When mechanical ventilation is used to maintain a safe

atmosphere, tests shall be made by a designated person to

ensure that the atmosphere is not hazardous.

(d)

Entry

into hazardous atmospheres.

Only designated persons shall enter hazardous atmospheres, in

which case the following shall apply:

(1)

Persons entering a space containing a hazardous atmosphere

shall be protected by respiratory and emergency protective

equipment meeting the requirements of subpart E of this part;

(2)

Persons entering a space containing a hazardous atmosphere

shall be instructed in the nature of the hazard, precautions

to be taken, and the use of protective and emergency

equipment. Standby observers, similarly equipped and

instructed, shall continuously monitor the activity of

employees within such space;

(3)

Except for emergency or rescue operations, employees shall not

enter into any atmosphere which has been identified as

flammable or oxygen deficient (less than 19.5% oxygen).

Persons who may be required to enter flammable or oxygen

deficient atmospheres in emergency operations shall be

instructed in the dangers attendant to those atmospheres and

instructed in the use of self-contained breathing apparatus,

which shall be utilized.

(4)

To prevent inadvertent employee entry into spaces that have

been identified as having hazardous, flammable or oxygen

deficient atmospheres, appropriate warning signs or equivalent

means shall be posted at all means of access to those spaces.

(e)

When the packaging of asbestos cargo leaks, spillage shall be

cleaned up by designated employees protected from the harmful

effects of asbestos as required by §1910.1001 of this

chapter.

[48

FR 30909, July 5, 1983, as amended at 49 FR 28551, July 13,

1984; 61 FR 5509, Feb. 13, 1996; 62 FR 40197, July 25, 1997;

65 FR 40938, June 30, 2000]

Back

to Top

Back

to Top

§1917.24 Carbon

monoxide.

(a)

Exposure

limits.

The carbon monoxide content of the atmosphere in a room,

building, vehicle, railcar, or any enclosed space shall be

maintained at not more than 50 parts per million (ppm)

(0.005%) as an eight hour average area level and employees

shall be removed from the enclosed space if the carbon

monoxide concentration exceeds a ceiling of 100 ppm (0.01%).

(b)

Testing.

Tests to determine carbon monoxide concentration shall be made

when necessary to ensure that employee exposure does not

exceed the limits specified in paragraph (a) of this section.

(c)

Instrumentation.

Tests for carbon monoxide concentration shall be made by

designated persons using gas detector tube units certified by

NIOSH under 30 CFR part 11 or other measuring instruments

whose accuracy is as great or greater.

(d)

Records.

A record of the date, time, location and results of carbon

monoxide tests shall be available for at least thirty (30)

days.

[48

FR 30909, July 5, 1983, as amended at 49 FR 28551, July 13,

1984; 61 FR 5509, Feb. 13, 1996; 62 FR 40197, July 25, 1997]

Back

to Top

Back

to Top

§1917.25 Fumigants,

pesticides, insecticides and hazardous preservatives (see also

§1917.2 Hazardous cargo, material, substance or

atmosphere).

(a)

At any time that the concentration in any space reaches the

level specified as hazardous by the fumigant manufacturer or

by Table Z-1 of 29 CFR 1910.1000, whichever is lower, all

employees shall be removed from the space and shall not be

permitted to re-enter until such time as tests demonstrate

that the atmosphere is safe.

(b)

Tests to determine the atmospheric concentration of chemicals

used to treat cargo shall be:

(1)

Appropriate for the hazard involved;

(2)

Conducted by designated persons; and

(3)

Performed at the intervals necessary to ensure that employee

exposure does not exceed the permissible exposure limit for

the chemical involved.

(c)

Results of any tests shall be available for at least 30 days.

Such records may be entered on any retrievable medium, and

shall be available for inspection.

(d)

Chemicals shall only be applied to cargoes by designated

persons.

(e)

Only designated persons shall enter hazardous atmospheres, in

which case the following provisions apply.

(1)

Persons entering a space containing a hazardous atmosphere

shall be protected by respiratory and emergency protective

equipment meeting the requirements of subpart E of this part;

and

(2)

Persons entering a space containing a hazardous atmosphere

shall be instructed in the nature of the hazard, precautions

to be taken, and the use of protective and emergency

equipment. Standby observers, similarly equipped and

instructed, shall continuously monitor the activity of

employees within such a space.

(f)

Signs shall be clearly posted where fumigants, pesticides or

hazardous preservatives have created a hazardous atmosphere.

These signs shall note the danger, identify specific chemical

hazards, and give appropriate information and precautions,

including instructions for the emergency treatment of

employees affected by any chemical in use.

(g)

In the case of containerized shipments of fumigated tobacco,

the contents of the container shall be aerated by opening the

container doors for a period of 48 hours after the completion

of fumigation and prior to loading. When tobacco is within

shipping cases having polyethylene or similar bag liners, the

aeration period shall be 72 hours. The employer shall obtain a

written warranty from the fumigation facility stating that the

appropriate aeration period has been met.

[48

FR 30909, July 5, 1983, as amended at 49 FR 28551, July 13,

1984; 61 FR 5509, Feb. 13, 1996; 62 FR 40197, July 25, 1997]

Back

to Top

Back

to Top

§1917.26 First

aid and lifesaving facilities.

(a)

Employers shall instruct employees to report every injury,

regardless of severity, to the employer.

(b)

A first aid kit shall be available at the terminal, and at

least one person holding a valid first aid certificate shall

be at the terminal when work is in progress.

(c)

First

aid kit.

First aid kits shall be weatherproof and shall contain

individual sealed packages for each item that must be kept

sterile. The contents of each kit shall be determined by a

person certified in first aid and cognizant of the hazards

found in marine cargo handling operations. The contents shall

be checked at intervals that allow prompt replacement of

expended items.

(d)

Stretchers.

(1) There shall be available for each vessel being worked one

Stokes basket stretcher, or its equivalent, permanently

equipped with bridles for attaching to the hoisting gear.

(2)

Stretchers shall be kept close to vessels and shall be

positioned to avoid damage to the stretcher.

(3)

A blanket or other suitable covering shall be available.

(4)

Stretchers shall have at least four sets of effective patient

restraints in operable condition.

(5)

Lifting bridles shall be of adequate strength, capable of

lifting 1,000 pounds (454 kg) with a safety factor of five,

and shall be maintained in operable condition. Lifting bridles

shall be provided for making vertical patient lifts at

container berths. Stretchers for vertical lifts shall have

foot plates.

(6)

Stretchers shall be maintained in operable condition. Struts

and braces shall be inspected for damage. Wire mesh shall be

secured and have no burrs. Damaged stretchers shall not be

used until repaired.

(7)

Stretchers in permanent locations shall be mounted to prevent

damage and shall be protected from the elements if located

out-of-doors. If concealed from view, closures shall be marked

to indicate the location of the life saving equipment.

(e)

Telephone or equivalent means of communication shall be

readily available.

(f)

A U.S. Coast Guard approved 30-inch (76.2 cm) life ring, with

at least 90 feet (27.43m) of line attached, shall be available

at readily accessible points at each waterside work area where

the employees' work exposes them to the hazard of drowning.

Employees working on any bridge or structure leading to a

detached vessel berthing installation shall wear U.S. Coast

Guard approved personal flotation devices except where

protected by railings, nets, or safety belts and lifelines. A

readily available portable or permanent ladder giving access

to the water shall also be provided within 200 feet (61 m) of

such work areas.

[48

FR 30909, July 5, 1983, as amended at 62 FR 40197, July 25,

1997; 65 FR 40938, June 30, 2000]

Back

to Top

Back

to Top

§1917.27 Personnel.

(a)

Qualifications

of machinery operators.

(1) Only those employees determined by the employer to be

competent by reason of training or experience, and who

understand the signs, notices and operating instructions and

are familiar with the signal code in use shall be permitted to

operate a crane, winch or other power operated cargo handling

apparatus, or any power operated vehicle, or give signals to

the operator of any hoisting apparatus. Exception:

Employees being trained and supervised by a designated person

may operate such machinery and give signals to operators

during training.

(2)

No employee known to have defective uncorrected eyesight or

hearing, or to be suffering from heart disease, epilepsy, or

similar ailments that may suddenly incapacitate the employee,

shall be permitted to operate a crane, winch or other

power-operated cargo handling apparatus or a power-operated

vehicle.

Note

to paragraph (a)(2):

OSHA is defining suddenly incapacitating medical ailments

consistent with the Americans with Disabilities Act (ADA), 42

U.S.C. 12101 (1990). Therefore, employers who act in

accordance with the employment provisions (Title I) of the ADA

(42 U.S.C. 12111-12117), the regulations implementing Title I

(29 CFR Part 1630), and the Technical Assistance Manual for

Title I issued by the Equal Employment Opportunity Commission

(Publication number: EEOC—M1A), will be considered as

being in compliance with this paragraph.

(b)

Supervisory

accident prevention proficiency.

(1) After October 3, 1985 immediate supervisors of

cargo-handling operations of more than five (5) persons shall

satisfactorily complete a course in accident prevention.

Employees newly assigned to supervisory duties after that date

shall be required to meet the provisions of this paragraph

within ninety (90) days of such assignment.

(2)

The course shall consist of instruction suited to the

particular operations involved.3

3The

following are recommended topics: (i) Safety responsibility

and authority; (ii) elements of accident prevention; (iii)

attitudes, leadership and motivation; (iv) hazards of

longshoring, including peculiar local circumstances; (v)

hazard identification and elimination; (vi) applicable

regulations; and (vii) accident investigations.

[48

FR 30909, July 5, 1983, as amended at 62 FR 40197, July 25,

1997; 65 FR 40938, June 30, 2000]

Back

to Top

Back

to Top

§1917.28 Hazard

communication (See also §1917.1(a)(2)(vi)).

Back

to Top

Back

to Top

§1917.29 Retention

of DOT markings, placards and labels.

(a)

Any employer who receives a package of hazardous material

which is required to be marked, labeled or placarded in

accordance with the U. S. Department of Transportation's

Hazardous Materials Regulations (49 CFR parts 171 through 180)

shall retain those markings, labels and placards on the

package until the packaging is sufficiently cleaned of residue

and purged of vapors to remove any potential hazards.

(b)

Any employer who receives a freight container, rail freight

car, motor vehicle, or transport vehicle that is required to

be marked or placarded in accordance with the Hazardous

Materials Regulations shall retain those markings and placards

on the freight container, rail freight car, motor vehicle or

transport vehicle until the hazardous materials which require

the marking or placarding are sufficiently removed to prevent

any potential hazards.

(c)

Markings, placards and labels shall be maintained in a manner

that ensures that they are readily visible.

(d)

For non-bulk packages which will not be reshipped, the

provisions of this section are met if a label or other

acceptable marking is affixed in accordance with the Hazard

Communication Standard (29 CFR 1910.1200).

(e)

For the purposes of this section, the term “hazardous

material” and any other terms not defined in this

section have the same definition as in the Hazardous Materials

Regulations (49 CFR parts 171 through 180).

[59

FR 36700, July 19, 1994]

Back

to Top

Back

to Top

§1917.30 Emergency

action plans.

(a)

Emergency

action plans—(1)

Scope

and application.

This paragraph (a) requires all employers to develop and

implement an emergency action plan.3a

The emergency action plan shall be in writing (except as

provided in paragraph (a)(5)(iv) of this section) and shall

cover those designated actions employers and employees must

take to ensure employee safety from fire and other

emergencies.

3aWhen

an employer directs his employees to respond to an emergency

that is beyond the scope of the Emergency Action Plan

developed in accordance with this section, then §1910.120(q)

of this chapter shall apply.

(2)

Elements.

The following elements, at a minimum, shall be included in the

plan:

(i)

Emergency escape procedures and emergency escape route

assignments;

(ii)

Procedures to be followed by employees who remain to operate

critical plant operations before they evacuate;

(iii)

Procedures to account for all employees after emergency

evacuation has been completed;

(iv)

Rescue and medical duties for those employees who are to

perform them;

(v)

The preferred means of reporting fires and other emergencies;

and

(vi)

Names or regular job titles of persons or departments that can

be contacted for further information or explanation of duties

under the plan.

(3)

Alarm

system.

The employer shall establish an employee alarm system that

provides warning for necessary emergency action and for

reaction time for safe escape of employees from the workplace

or the immediate work area.

(4)

Evacuation.

The employer shall establish the types of evacuation to be

used in emergency circumstances.

(5)

Training.

(i) Before implementing the emergency action plan, the

employer shall designate and train a sufficient number of

persons to assist in the safe and orderly emergency evacuation

of employees.

(ii)

The employer shall review the plan with each employee covered

by the plan at the following times:

(A)

Initially when the plan is developed;

(B)

Whenever the employee's responsibilities or designated actions

under the plan change; and

(C)

Whenever the plan is changed.

(iii)

The employer shall review with each employee upon initial

assignment those parts of the plan that the employee must know

to protect the employee in the event of an emergency. The

written plan shall be kept at the workplace and be made

available for employee review.

(iv)

Employers with 10 or fewer employees may communicate the plan

orally to employees and need not maintain a written plan

(b)

[Reserved]

[62

FR 40198, July 25, 1997, as amended at 65 FR 40938, June 30,

2000]

Back

to Top

Back

to Top

Subpart

C—Cargo Handling Gear and Equipment

Back

to Top

Back

to Top

§1917.41 House

falls.

(a)

Span beams shall be secured to prevent accidental

dislodgement.

(b)

A safe means of access shall be provided for employees working

with house fall blocks.

(c)

Designated employees shall inspect chains, links, shackles,

swivels, blocks and other loose gear used in house fall

operations before each day's use. Defective gear shall not be

used.

Back

to Top

Back

to Top

§1917.42 Miscellaneous

auxiliary gear.

(a)

Routine

inspection.

(1) At the completion of each use, loose gear such as slings,

chains, bridles, blocks and hooks shall be so placed as to

avoid damage to the gear. Loose gear shall be inspected and

any defects corrected before reuse.

(2)

All loose gear shall be inspected by the employer or his

authorized representative before each use and, when necessary,

at intervals during its use, to ensure that it is safe. Any

gear which is found upon such inspection to be visibly unsafe

shall not be used until it is made safe.

(3)

Defective gear shall not be used. Distorted hooks, shackles or

similar gear shall be discarded.

(b)

Wire

rope and wire rope slings.

(1) The employer shall ascertain and adhere to the

manufacturer's recommended ratings for wire rope and wire rope

slings and shall have such ratings available for inspection.

When the manufacturer is unable to supply such ratings, the

employer shall use the tables for wire rope and wire rope

slings found in American National Safety Standard for Slings,

ANSI B30.9-1971. A design safety factor of at least five shall

be maintained for the common sizes of running wire used as

falls, in purchases or in such uses as light load slings. Wire

rope with a safety factor of less than five may be used only:

(i)

In specialized equipment, such as but not limited to cranes,

designed to be used with lesser wire rope safety factors;

(ii)

In accordance with design factors in standing rigging

applications; or

(iii)

For heavy lifts or other purposes for which a safety factor of

five is impracticable and for which the employer can

demonstrate that equivalent safety is ensured.

(2)

Wire rope or wire rope slings having any of the following

conditions shall not be used:

(i)

Ten randomly distributed broken wires in one rope lay or three

or more broken wires in one strand in one rope lay;

(ii)

Kinking, crushing, bird caging or other damage resulting in

distortion of the wire rope structure;

(iii)

Evidence of heat damage;

(iv)

Excessive wear or corrosion, deformation or other defect in

the wire or attachments, including cracks in attachments;

(v)

Any indication of strand or wire slippage in end attachments;

or

(vi)

More than one broken wire in the close vicinity of a socket or

swaged fitting.

(3)

Protruding ends of strands in splices on slings and bridles

shall be covered or blunted. Coverings shall be removable so

that splices can be examined. Means used to cover or blunt

ends shall not damage the wire.

(4)

Where wire rope clips are used to form eyes, the employer

shall adhere to the manufacturers' recommendations, which

shall be made available for inspection. If “U”

bolt clips are used and the manufacturers' recommendations are

not available, Table C-1 shall be used to determine the number

and spacing of the clips. “U” bolts shall be

applied with the “U” section in contact with the

dead end of the rope.

Table

C-1—Number and Spacing of U-Bolt Wire Rope Clips

Improved

plow steel, rope diameter (inches/(cm))

|

Minimum

number of clips

|

Minimum

spacing

(inches/(cm))

|

Drop

forged

|

Other

material

|

1/2

or less (1.3)

|

3

|

4

|

3

(7.6)

|

5/8

(1.6)

|

3

|

4

|

33/4

(9.5)

|

3/4

(1.9)

|

4

|

5

|

41/2

(11.4)

|

7/8

(2.2)

|

4

|

5

|

51/4

(13.3)

|

1

(2.5)

|

5

|

7

|

6

(15.2)

|

11/8

(2.9)

|

6

|

7

|

63/4

(17.1)

|

11/4

(3.2)

|

6

|

8

|

71/2

(19.1)

|

13/8

(3.5)

|

7

|

8

|

81/4

(21.0)

|

11/2

(3.8)

|

7

|

9

|

9

(22.9)

|

(5)

Wire rope shall not be secured by knots.

(6)

Eyes in wire rope bridles, slings, bull wires, or in single

parts used for hoisting shall not be formed by wire rope clips

or knots.

(7)

Eye splices in wire ropes shall have at least three tucks with

a whole strand of the rope and two tucks with one-half of the

wire cut from each strand. Other forms of splices or

connections which are shown to be equivalently safe may be

used.

(8)

Except for eye splices in the ends of wires and for endless

rope slings, each wire rope used in hoisting or lowering, or

in bulling cargo, shall consist of one continuous piece

without knot or splice.

(c)

Natural

fiber rope.

(1) The employer shall ascertain the manufacturers' ratings

for the specific natural fiber rope used and have such ratings

available for inspection. The manufacturers' ratings shall be

adhered to and a minimum design safety factor of five

maintained.

(2)

Eye splices shall consist of at least three full tucks. Short

splices shall consist of at least six full tucks, three on

each side of the center line.

(d)

Synthetic

rope.

(1) The employer shall adhere to the manufacturers' ratings

and use recommendations for the specific synthetic fiber rope

used and shall make such ratings available for inspection.

(2)(i)

Unless otherwise recommended by the manufacturer, when

synthetic fiber ropes are substituted for fiber ropes of less

than three inches (7.62 cm) in circumference, the substitute

shall be of equal size. Where substituted for fiber rope of

three inches or more in circumference, the size of the

synthetic rope shall be determined from the formula:

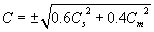

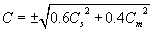

View

or download PDF

Where

C = the required circumference of the synthetic rope in

inches, Cs= the circumference to the nearest one-quarter inch

of a synthetic rope having a breaking strength not less than

that of the size fiber rope that is required by paragraph (c)

of this section and Cm= the circumference of the fiber rope in

inches that is required by paragraph (c) of this section.

(ii)

In making such substitution, it shall be ascertained that the

inherent characteristics of the synthetic fiber are suitable

for hoisting.

(e)

Removal

of natural and synthetic rope from service.

Natural and synthetic rope having any of the following defects

shall be removed from service:

(1)

Abnormal wear;

(2)

Powdered fiber between strands;

(3)

Sufficient cut or broken fibers to affect the capability of

the rope;

(4)

Variations in the size or roundness of strands;

(5)

Discolorations other than stains not associated with rope

damage;

(6)

Rotting; or

(7)

Distortion or other damage to attached hardware.

(f)

Thimbles.

Properly fitting thimbles shall be used where any rope is

secured permanently to a ring, shackle or attachment, where

practicable.

(g)

Synthetic

web slings.

(1) Slings and nets or other combinations of more than one

piece of synthetic webbing assembled and used as a single unit

(synthetic web slings) shall not be used to hoist loads in

excess of the sling's rated capacity.

(2)

Synthetic web slings shall be removed from service if they

exhibit any of the following defects:

(i)

Acid or caustic burns;

(ii)

Melting or charring of any part of the sling surface;

(iii)

Snags, punctures, tears or cuts;

(iv)

Broken or worn stitches; or

(v)

Distortion or damage to fittings.

(vi)

Display of visible warning threads or markers designed to

indicate excessive wear or damage.

(3)

Defective synthetic web slings removed from service shall not

be returned to service unless repaired by a sling manufacturer

or similar entity. Each repaired sling shall be proof tested

by the repairer to twice the slings' rated capacity prior to

its return to service. The employer shall retain a certificate

of the proof test and make it available for examination.

(4)

Synthetic web slings provided by the employer shall only be

used in accordance with the manufacturer's use

recommendations, which shall be available.

(5)

Fittings shall have a breaking strength at least equal to that

of the sling to which they are attached and shall be free of

sharp edges.

(h)

Chains

and chain slings used for hoisting.

(1) The employer shall adhere to the manufacturer's

recommended ratings for safe working loads for the sizes of

wrought iron and alloy steel chains and chain slings used and

shall have such ratings available. When the manufacturer is

unable to provide such ratings, the employer shall use the

tables for chains and chain slings found in American National

Safety Standard for Slings, ANSI B30.9-1971.

(2)

Proof coil steel chain, also known as common or hardware

chain, and other chain not recommended by the manufacturer for

slinging or hoisting shall not be used for slinging or

hoisting.

(3)(i)

Sling chains, including end fastenings, shall be inspected for

visible defects before each day's use and as often as

necessary during use to ensure integrity of the sling.

(ii)

Thorough inspections of chains in use shall be made quarterly

to detect wear, defective welds, deformation or increase in

length or stretch. The month of inspection shall be indicated

on each chain by color of paint on a link or by other equally

effective means.

(iii)

Chains shall be removed from service when maximum allowable

wear, as indicated in Table C-2, is reached at any point of

link.

(iv)

Chain slings shall be removed from service when stretch has

increased the length of a measured section by more than five

percent; when a link is bent, twisted or otherwise damaged; or

when a link has a raised scarf or defective weld.

(v)

Only designated persons shall inspect chains used for slinging

and hoisting.

Table

C-2—Maximum Allowable Wear at Any Point of Link

Chain

size

|

Maximum

allowable wear

|

Inches

|

(cm)

|

Inches

|

(cm)

|

1/4(9/32)

|

(0.6)

|

3/64

|

(0.1)

|

3/8

|

(1.0)

|

5/64

|

(0.2)

|

1/2

|

(1.3)

|

7/64

|

(0.3)

|

5/8

|

(1.6)

|

9/64

|

(0.4)

|

3/4

|

(1.9)

|

5/32

|

(0.4)

|

7/8

|

(2.2)

|

11/64

|

(0.4)

|

1

|

(2.5)

|

3/16

|

(0.5)

|

11/8

|

(2.9)

|

7/32

|

(0.6)

|

11/4

|

(3.2)

|

1/4

|

(0.6)

|

13/8

|

(3.5)

|

9/32

|

(0.7)

|

11/2

|

(3.8)

|

5/16

|

(0.8)

|

13/4

|

(4.4)

|

11/32

|

(0.9)

|

(4)

Chains shall be repaired only under qualified supervision.

Links or portions of chain defective under any of the criteria

of paragraph (h)(3)(iii) of this section shall be replaced

with properly dimensioned links or connections of material

similar to those of the original chain. Before repaired chains

are returned to service, they shall be tested to the proof

load recommended by the manufacturer of the original chain.

Tests shall be performed by the manufacturer or shall be

certified by an agency accredited for the purpose under part

1919 of this chapter. Test certificates shall be available for

inspection.

(5)

Wrought iron chains in constant use shall be annealed or

normalized at intervals not exceeding six months. Heat

treatment certificates shall be available for inspection.

Alloy chains shall not be annealed.

(6)

Kinked or knotted chains shall not be used for lifting. Chains

shall not be shortened by bolting, wiring or knotting.

Makeshift links or fasteners such as wire, bolts or rods shall

not be used.

(7)

Hooks, rings, links and attachments affixed to sling chains

shall have rated capacities at least equal to that of the

chains to which they are attached.

(8)

Chain slings shall bear identification of size, grade and

rated capacity.

(i)

Shackles.

(1) If available, the manufacturer's recommended safe working

loads for shackles shall not be exceeded. In the absence of

manufacturer's recommendations, Table C-3 shall apply.

(2)

Screw pin shackles used aloft in house fall or other gear,

except in cargo hook assemblies, shall have their pins moused

or otherwise effectively secured.

Table

C-3—Safe Working Loads for Shackles

Material

size

|

Pin

diameter

|

Safe

working load in 2,000 lb tons

|

Inches

|

(cm)

|

Inches

|

(cm)

|

1/2

|

(1.3)

|

5/8

|

(1.6)

|

1.4

|

5/8

|

(1.6)

|

3/4

|

(1.9)

|

2.2

|

3/4

|

(1.9)

|

7/8

|

(2.2)

|

3.2

|

7/8

|

(2.2)

|

1

|

(2.5)

|

4.3

|

1

|

(2.5)

|

11/8

|

(2.9)

|

5.6

|

11/8

|

(2.9)

|

11/4

|

(3.2)

|

6.7

|

11/4

|

(3.2)

|

13/8

|

(3.5)

|

8.2

|

13/8

|

(3.5)

|

11/2

|

(3.8)

|

10.0

|

11/2

|

(3.8)

|

15/8

|

(4.1)

|

11.9

|

13/4

|

(4.4)

|

2

|

(5.1)

|

16.2

|

2

|

(5.1)

|

21/4

|

(5.7)

|

21.2

|

(j)

Hooks

other than hand hooks.

(1) The manufacturers' recommended safe working loads for

hooks shall not be exceeded. Hooks other than hand hooks shall

be tested in accordance with §1917.50(c)(6).

(2)

Bent or sprung hooks shall be discarded.

(3)

Teeth of case hooks shall be maintained in safe condition.

(4)

Jaws of patent clamp-type plate hooks shall be maintained in

condition to grip plates securely.

(5)

Loads shall be applied to the throat of the hook only.

(k)

Pallets.

(1) Pallets shall be made and maintained to safely support and

carry loads being handled. Fastenings of reusable pallets used

for hoisting shall be bolts and nuts, drive screws (helically

threaded nails), annular threaded nails or fastenings of

equivalent holding strength.

(2)

Damaged pallets shall be stored in designated areas and

identified.

(3)

Reusable wing or lip-type pallets shall be hoisted by bar

bridles or other suitable gear and shall have an overhanging

wing or lip of at least three inches (7.62cm). They shall not

be hoisted by wire slings alone.

(4)

Loaded pallets that do not meet the requirements of this

paragraph shall be hoisted only after being placed on pallets

meeting such requirements or shall be handled by other means

providing equivalent safety.

(5)

Bridles for handling flush end or box-type pallets shall be

designed to prevent disengagement from the pallet under load.

(6)

Pallets shall be stacked or placed to prevent falling,

collapsing or otherwise causing a hazard under standard

operating conditions.

(7)

Disposable pallets intended only for one use shall not be

reused for hoisting.

[48

FR 30909, July 5, 1983, as amended at 62 FR 40198, July 25,

1997; 65 FR 40938, June 30, 2000]

Back

to Top

Back

to Top

§1917.43 Powered

industrial trucks.

(a)

Applicability.

This section applies to every type of powered industrial truck

used for material or equipment handling within a marine

terminal. It does not apply to over-the-road vehicles.

(b)

General.

(1) After October 3, 1983, modifications, such as adding

counterweights, that might affect the vehicle's capacity or

safety shall not be performed without either the

manufacturer's prior written approval or the written approval

of a professional engineer experienced with the equipment who

has consulted with the manufacturer, if available. Capacity,

operation and maintenance instruction plates, tags or decals

shall be changed to conform to the equipment as modified.

(2)

Unauthorized personnel shall not ride on powered industrial

trucks. A safe place to ride shall be provided when riding is

authorized.

(3)

When a powered industrial truck is left unattended,

load-engaging means shall be fully lowered, controls

neutralized and brakes set. Unless the truck is in view and

within 25 feet (7.62 m) of the operator, power shall be shut

off. Wheels shall be blocked or curbed if the truck is on an

incline.

(4)

Powered industrial trucks shall not be operated inside highway

vehicles or railcars having damage which could affect

operational safety.

(5)

Powered industrial trucks shall be marked with their rated

capacities, which shall be visible to the operator.

(6)

Only stable and safely arranged loads within the rated

capacity of the truck shall be handled.

(7)

The employer shall direct drivers to ascend and descend grades

slowly.

(8)

The employer shall direct drivers to slow down and sound the

horn at crossaisles and other locations where visibility is

obstructed.

(9)

If the load obstructs the forward view, the employer shall

direct drivers to travel with the load trailing.

(10)

Steering knobs shall not be used unless the truck is equipped

with power steering.

(11)

When powered industrial trucks use cargo lifting devices that

have a means of engagement hidden from the operator, a means

shall be provided to enable the operator to determine that the

cargo has been engaged.

(12)

When cargo is being towed on pipe trucks or similar equipment,

a safe means shall be provided to protect the driver from

sliding loads.

(c)

Maintenace.

(1) Only designated persons shall perform maintenance and

repair.

(2)

Batteries on all powered trucks shall be disconnected during

repairs to the primary electrical system unless power is

necessary for testing and repair. On trucks equipped with

systems capable of storing residual energy, that energy shall

be safely discharged before work on the primary electrical

system begins.

(3)

Replacement parts whose function might affect operational

safety shall be equivalent in strength and performance

capability to the original parts which they replace.

(4)

Braking systems or other mechanisms used for braking shall be

operable and in safe condition.

(5)

Powered industrial trucks shall be maintained in safe working

order. Safety devices shall not be removed or made inoperative

except as otherwise provided in this section. Trucks with a

fuel system leak or any other safety defect shall not be

operated.

(6)

Those repairs to the fuel and ignition systems of industrial

trucks which involve fire hazards shall be conducted only in

locations designated as safe for such repairs.

(d)

Approved

trucks—(1)

Approved

power-operated industrial truck

means one listed or approved for the intended use by a

nationally recognized testing laboratory.

(2)

Approved trucks acquired and used after February 15, 1972,

shall bear a label or other identification indicating testing

laboratory approval.

(3)

When the atmosphere in an area is hazardous and the provisions

of United States Coast Guard regulations at 33 CFR 126.15(e)

do not apply, only power-operated industrial trucks approved

for such locations shall be used.

(e)

Fork

lift trucks—(1)

Overhead

guards.

(i) When operators are exposed to overhead falling hazards,

fork lift trucks shall be equipped with securely attached

overhead guards. Guards shall be constructed to protect the

operator from falling boxes, cartons, packages, or similar

objects.

(ii)

Overhead guards shall not obstruct the operator's view, and

openings in the top of the guard shall not exceed six inches

(15.24 cm) in one of the two directions, width or length.

Larger openings are permitted if no opening allows the

smallest unit of cargo being handled to fall through the

guard.

(iii)

Overhead guards shall be built so that failure of the

vehicle's mast tilting mechanism will not displace the guard.

(iv)

An overhead guard, otherwise required by this paragraph, may

be removed only when it would prevent a truck from entering a

work space and if the operator is not exposed to low overhead

obstructions in the work space.

(v)

Overhead guards shall be large enough to extend over the

operator during all truck operations, including forward tilt.

(2)

Load

backrest extensions.

Where necessary to protect the operator, fork lift trucks