1773ss09

1773ss09.doc

National Emission Standards for Hazardous Air Pollutants (NESHAP) for Hazardous Waste Combustors (Renewal)

OMB: 2050-0171

Supporting Statement for

EPA Information Collection Request Number 1773.09

(OMB Control Number 2050-0171)

“National Emission Standards for Hazardous Air Pollutants

(NESHAP) for Hazardous Waste Combustors (Renewal)”

August, 2008

Contents

1. IDENTIFICATION OF THE INFORMATION COLLECTION 1

1(a). TITLE AND NUMBER OF THE INFORMATION COLLECTION 1

1(b). SHORT CHARACTERIZATION/ABSTRACT 1

2. NEED FOR AND USE OF THE COLLECTION 2

2(a). NEED AND AUTHORITY FOR THE COLLECTION 2

3. NONDUPLICATION, CONSULTATIONS, AND OTHER COLLECTION CRITERIA 2

3(b). PUBLIC NOTICE REOUIRED PRIOR TO ICR SUBMISSION TO OMB 3

3(d). EFFECTS OF LESS FREQUENT COLLECTION 3

4. RESPONDENTS AND THE INFORMATION COLLECTED 4

4(a). RESPONDENTS AND NAICS CODES 4

FACILITIES SUBJECT TO THESE REGULATIONS 5

COMPLIANCE WITH THE STANDARDS AND OPERATING REQUIREMENTS (Section 63.1206) 5

PERFORMANCE TESTING REQUIREMENTS (Section 63.1207) 12

MONITORING REQUIREMENTS (Section 63.1209) 17

NOTIFICATION REQUIREMENTS (Section 63.1210) 26

RECORDKEEPING AND REPORTING REQUIREMENTS (Section 63.1211) 30

Calibration Drift (CD) and Zero Drift (ZD) Assessment and Daily System Audit 35

COMPLIANCE WITH THE STANDARDS AND OPERATING REQUIREMENTS 37

PERFORMANCE TESTING REQUIREMENTS 39

RECORDKEEPING AND REPORTING REQUIREMENTS 42

COMPLIANCE DATE BE EXTENDED TO INSTALL POLLUTION PREVENTION OR WASTE MINIMIZATION CONTROLS 43

QUALITY ASSURANCE PROCEDURE FOR CONTINUOUS EMISSIONS 43

MONITORS USED FOR HAZARDOUS WASTE COMBUSTORS 43

5(b). COLLECTION METHODOLOGY AND MANAGEMENT 44

5(c). SMALL ENTITY FLEXIBILITY 44

6. ESTIMATING THE BURDEN AND COST OF THE COLLECTION 44

Operating and Maintenance Costs 45

6(c). AGENCY BURDEN AND COST 45

6(d). RESPONDENT UNIVERSE AND TOTAL BURDEN AND COSTS 46

WHO IS SUBJECT TO THESE REGULATIONS 47

STANDARDS FOR HAZARDOUS WASTE BURNING INCINERATORS, CEMENT KILNS, AND LIGHTWEIGHT AGGREGATE KILNS 47

COMPLIANCE WITH THE STANDARDS AND OPERATING REQUIREMENTS 47

PERFORMANCE TESTING REQUIREMENTS 49

RECORDKEEPING AND REPORTING REQUIREMENTS 52

COMPLIANCE DATE BE EXTENDED TO INSTALL POLLUTION PREVENTION OR WASTE MINIMIZATION CONTROLS 53

1. IDENTIFICATION OF THE INFORMATION COLLECTION

1(a). TITLE AND NUMBER OF THE INFORMATION COLLECTION

This Information Collection Request (ICR) is entitled “National Emission Standards for Hazardous Air Pollutants (NESHAPS) from Hazardous Waste Combustors,” EPA ICR Number # 1773.09 (OMB Control Number 2050-0171). This ICR covers Paperwork Reduction Act requirements for regulations at 40 CFR part 63, subpart EEE.

1(b). SHORT CHARACTERIZATION/ABSTRACT

The United States Environmental Protection Agency promulgated the “Maximum Achievable Control Technology” (MACT) standards for hazardous waste combustors (HWCs) on September 30, 1999 (64 CFR 53038). HWCs include the following hazardous waste burning source categories: (a) incinerators, (b) cement kilns, (c) lightweight aggregate kilns, (d) industrial, commercial and institutional boilers, and (e) hydrochloric acid production furnaces. These standards are codified in 40 CFR part 63 subpart EEE, and this ICR covers them. This ICR renews the ICR # 1773.08 that will expire in September 2008.

Interim MACT standards for the “Phase I” hazardous waste burning source categories -- incinerators, cement kilns, and lightweight aggregate kilns were promulgated on February 13 and 14, 2002 (see 67 FR 6792 and 67 FR 6968). The MACT emission standards for “Phase II” hazardous waste burning industrial and institutional /commercial boilers and hydrochloric acid (HCl) production furnaces, and the final MACT standards for the Phase I sources were promulgated on October 12, 2005 (70 FR 50402).

We note that the paperwork requirements of the RCRA provisions (40 CFR parts 264 thru 270) that govern the hazardous waste combustion units of this ICR such as storage, closure etc. are not covered in this ICR, and are accounted for in ICR # 1361.10 (OMB control # 2050-0073).

Subpart EEE of 40 CFR part 63 requires HWCs to perform testing and monitoring and submit various reports and perform recordkeeping activities in order to demonstrate compliance with emission standards. Much of the information is kept on-site at the facilities; some is also submitted to the EPA or the delegated state agency. Facilities and EPA use the data to ensure compliance with MACT standards.

After EPA’s issuance of the MACT rule in October 2005, EPA received several reconsideration petitions relating to certain issues presented by this rule. EPA has finalized some of these petitions. (see 71 FR 14665, 52564), but has not yet issued a final determination on reconsideration on all of them.. Following the promulgation of the MACT rule, the United States Court of Appeals for the District of Columbia Circuit has issued several opinions construing section 112 (d) of the Clean Air Act, and one of those opinions has called into question the legality of some of the standards for hazardous waste combustors. While these developments may result in changes to standards finalized, this ICR is based on rules currently in force. The ICR will be revised as and when changes are promulgated.

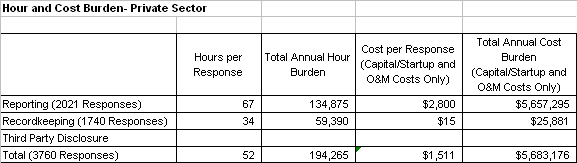

In summary, this ICR estimates recordkeeping and reporting burden of:

For the regulated community, 194,265 hours per year. The annual start-up and O& M Costs will be $105,459 and $5,577,717 respectively.

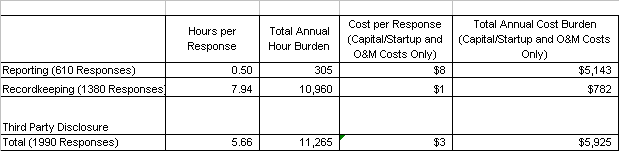

For the federal government (including EPA regional offices), 11,265 hours per year.

For state and local offices, 5632 hours per year.

(Please see sections 6(e) and 6(f) for a more detailed explanation)

2. NEED FOR AND USE OF THE COLLECTION

2(a). NEED AND AUTHORITY FOR THE COLLECTION

The EPA, under authority of Section 112 of the Clean Air Act, has established national emissions standards for hazardous air pollutants for hazardous waste burning incinerators, cement and lightweight aggregate kilns, boilers and HCl Production Furnaces. The main purpose of the Clean Air Act is to protect and enhance the quality of the Nation’s air resources, and to promote the public health and welfare and the productive capacity of the population. To this end, Sections 112(a) and (d) of the Clean Air Act direct EPA to set standards for hazardous air pollutants. The records and reports required by the information collection are used to show compliance with the standards.

2(b). PRACTICAL UTILITY AND USERS OF THE DATA

The data collected for HWC system operations and testing is used by facility owners and operators, and by EPA or the implementing agency. Data maintained in records are used to monitor results of testing, inspections, and the operation of air pollution control systems, as well as to demonstrate compliance with regulations. Notifications and submitted monitoring data are used by EPA or the implementing agency to evaluate construction or reconstruction plans, test and operating plans, test results, facility operation, and whether facilities qualify for certain exemptions and alternative monitoring or testing methods.

3. NONDUPLICATION, CONSULTATIONS, AND OTHER COLLECTION CRITERIA

3(a). NONDUPLICATION

The information collections covered in this ICR are not available from sources other than the respondents. No other Federal agency collection satisfies the statutory requirements of Section 112 of the Clean Air Act. None of this information is duplicative of other information collected by other EPA offices or other Federal agencies.

3(b). PUBLIC NOTICE REQUIRED PRIOR TO ICR SUBMISSION TO OMB

In compliance with the Paperwork Reduction Act of 1995 (PRA), EPA issued a public notice in the Federal Register (see 73 FR 24977, May 6, 2008) detailing the burden hours and costs associated with the regulations at 40 CFR part 63, subpart EEE for hazardous waste combustors, and requested comments to be submitted to EPA or the Office of Management and Budget (OMB). No comments were received.

3(c). CONSULTATIONS

EPA has made efforts to consult with the regulated community, stakeholders, the general public, State and industry officials, and appropriate Federal agencies in the development of the HWC MACT Replacement Rule, and the consequent burden imposed due to its various provisions. The trade associations of each category of stakeholders (such as the Cement Kiln Recycling Coalition, American Chemistry Council (previously known as the Chemical Manufacturers Association), Environmental Technology Council, and Coalition of Responsible Waste Incineration) actively and routinely interact with EPA officials at the headquarters and regional levels on the issues of concern. Since some of the regulated facilities are owned by other agencies of the Federal government (including the Department of Defense and the Department of Energy), EPA also held similar consultations with them. Details of these meetings are a part of the administrative record of the MACT Replacement Rule and are contained in the rule docket # EPA-HQ-OAR-2004-0022.

3(d). EFFECTS OF LESS FREQUENT COLLECTION

EPA has carefully considered the burden imposed upon the regulated community by the regulations. The Agency is confident that whose activities required of respondents are necessary, and to the extent possible, minimize the burden imposed. EPA believes that, if the minimal requirements specified under the regulations are not met, EPA will be unable to fulfill its Congressional mandate to protect public health and the environment. Additionally, we have made efforts to integrate monitoring, compliance testing, and recordkeeping requirements of the CAA and RCRA so that the facilities are able to avoid the burden of duplicate submissions under two potentially different regulatory compliance schemes.

3(e). GENERAL GUIDELINES

This ICR adheres to the guidelines stated in the Paperwork Reduction Act of 1995; OMB’s implementing regulations, EPA’s “Information Collection Request Handbook,” and other applicable OMB guidance. It is necessary for facilities to retain records for three (3) years for EPA to ensure compliance with the regulations. The recordkeeping burden for such a requirement is not significant, and has been included in this ICR.

3(f). CONFIDENTIALITY

Section 3007(b) of RCRA and 40 CFR Part 2, Subpart B, which define EPA’s general policy on the public disclosure of information, contain provisions for confidentiality. However, the Agency does not anticipate that businesses will assert a claim of confidentiality covering the information collection requirements in this ICR. If such claim is made, EPA will treat the information in accordance with the regulations cited above. EPA also has ensured that this information collection complies with the Privacy Act of 1974 and OMB Circular 108.

3(g). SENSITIVE QUESTIONS

No questions of a sensitive nature are included in any of the information collection requirements.

4. RESPONDENTS AND THE INFORMATION COLLECTED

4(a). RESPONDENTS AND NAICS CODES

The following is a list of North American Industry Classification System (NAICS) codes and Standard Industrial Classification (SIC) codes associated with industries most likely to be affected by the information collection requirements covered in this ICR:

Category |

NAICS code |

SIC code |

Examples of potentially regulated entities |

Any industry that combusts hazardous waste as defined in the final rule |

562211 |

4953 |

Incinerator, hazardous waste |

327310, |

3241 |

Cement manufacturing, clinker production |

|

327992 |

3295 |

Ground or treated mineral and earth manufacturing |

|

325 |

28 |

Chemical Manufacturers |

|

324 |

29 |

Petroleum Refiners |

|

331 |

33 |

Primary Aluminum |

|

333 |

38 |

Photographic equipment and supplies |

|

488, 561, 562 |

49 |

Sanitary Services, N.E.C. |

|

421 |

50 |

Scrap and waste materials |

|

422 |

51 |

Chemical and Allied Products, N.E.C |

|

512, 541, 561, 812 |

73 |

Business Services, N.E.C. |

|

512, 514, 541, 711 |

89 |

Services, N.E.C. |

|

924 |

95 |

Air, Water and Solid Waste Management |

4(b). INFORMATION COLLECTED

FACILITIES SUBJECT TO THESE REGULATIONS

(i) Data items

All hazardous waste combustors -- hazardous waste burning cement kilns (CKs), hazardous waste incinerators, hazardous waste burning lightweight aggregate kilns (LWAKs), hazardous waste burning liquid and solid fuel boilers, and hazardous waste burning HCl Production Furnaces -- are subject to this rule and will read the 40 CFR Part 63, Subparts A and EEE regulations. The universe of affected facilities is covered in detail in section 6(d) of this document below.

(ii) Respondent activities

Read 40 CFR Part 63, Subparts A and EEE

STANDARDS FOR HAZARDOUS WASTE BURNING INCINERATORS, LIGHTWEIGHT AGGREGATE KILNS, CEMENT KILNS, LIQUID FUEL BOILERS, SOLID FUEL BOILERS, AND HCL PRODUCTION FURNACES (Sections 63.1203-63.1205, Sections 63.1216-63.1218, and 63.1219-63.1221)

Replacement MACT standards for hazardous waste burning incinerators, lightweight aggregate kilns, and cement kilns (Phase I units) are covered in Sections 63.1219 through 63.1221. MACT Standards for liquid fuel boilers, solid fuel boilers, and HCl Production Furnaces are covered in Sections 63.1216 through 63.1218. For Phase I sources the Standards specified in section 63.1203 through 63.1205 apply until compliance with the replacement standards. The MACT Standards apply to the following HAPs: particulate matter (PM), CO (carbon monoxide)/HC (hydrocarbons), total chlorine (hydrogen chloride (HCl) and Chlorine gas (Cl2)), semivolatile metals (cadmium and lead), low volatile metals (chromium, arsenic, and beryllium), PCDD/PCDF (dioxins and furans), mercury, and DRE (destruction and removal efficiency).

Additional recordkeeping or reporting requirements associated with these activities are discussed in the various sections below.

COMPLIANCE WITH THE STANDARDS AND OPERATING REQUIREMENTS (Section 63.1206)

Compliance with Alternative MACT Standards

(i) Data items

Under Section 63.1206(b)(1)(ii), when hazardous waste is not in the combustion chamber (i.e., the hazardous waste feed to the combusted has been cutoff-for a period of time not less than the hazardous waste residence time), HWCs may elect to show compliance with other applicable MACT standards (such as subparts LLL, DDDDD, or NNNNN) in lieu of the HWC standards. Specifically, they must document in the operating record compliance with other applicable MACT requirements in lieu of the HWC MACT emission standards and operating requirements of Subpart EEE.

(ii) Respondent activities

When hazardous waste is not in the combustion chamber, document in the operating record compliance with other applicable MACT requirements in lieu of the requirements of HWC MACT Standards in Part 63 Subpart EEE.

Extension of Compliance with Emission Standards

(i) Data items

Under Sections 63.1206(b)(4), 63.6(i), and 63.1213 HWCs may request EPA for an extension of compliance with the emission standards of Subpart EEE. Section 63.6(i)(4) allows up to one (1) additional year to comply with the standard. The request for the one-year extension shall be submitted not later than four (4) months before the affected source’s compliance date.

In addition, under Section 63.6(i)(5), existing sources that have installed best available control technology (BACT) or technology required to meet lowest achievable emission rate (LAER) prior to the MACT rule may request that the EPA grant an extension allowing the source five (5) years from the date on which such installation was achieved to comply with the standard. Any request for the five-year extension must be submitted not later than 120 days after the promulgation date of the standard.

As required by Section 63.6(i)(6), any request for an extension of compliance must include the following information:

A description of the controls to be installed to comply with the standard;

A compliance schedule;

For the five-year extension, all information needed to demonstrate the effectiveness of the installation of BACT or technology to meet LAER.

Under Section 63.10(d)(4), affected sources required to submit progress reports as a condition of receiving an extension of compliance must submit such report to the EPA by the dates specified in the written extension of compliance.

(ii) Respondent activities

Prepare and submit a request for an extension of compliance; and

Prepare and submit a progress report, as applicable.

Changes in Design, Operation, or Maintenance

(i) Data items

Under Section 63.1206(b)(5)(i), if a HWC plans to change the design, operation, or maintenance practices of the source in a manner that may adversely affect compliance with any emission standard that is not monitored with a CEMS, the HWC must notify EPA at least 60 days prior to the change, unless circumstances are documented that dictate such prior notice is not feasible. The notification must include:

A description of the changes and which emission standards may be affected; and

A comprehensive performance test schedule and test plan that will document compliance with the affected emission standards.

The HWC must conduct a comprehensive performance test to document compliance with the affected emission standards, establish operating parameter limits, and submit to the EPA a Notification of Compliance under Sections 63.1207(j) and 63.1210(d).

Additionally, if it is determined that a change will not adversely affect compliance with the emission standards or operating requirements, the HWC must document the change in the operating record upon making such change. The performance test plan, Documentation of Compliance, Notification of Compliance, and start-up, shutdown, and malfunction plan must be revised, as necessary, to reflect these changes.

Additionally, under Section 63.1206(b)(5)(i)(C), a request may be made to burn hazardous waste for more than 720 hours for purposes other than testing or pre-testing, after making a change in the design or operation that could affect compliance with the emission standards and prior to submitting a revised Notification of Compliance.

(ii) Respondent activities

Prepare and submit a notification of change in design, operation, or maintenance;

Conduct a comprehensive performance test to document compliance with emissions standards and establish operating limits;

Document change in the operating record if it is determined that the change will not adversely affect compliance with emission standards or operating requirements;

Revise, as necessary, the performance test plan, Documentation of Compliance, Notification of Compliance, and start-up, shutdown, and malfunction plan to reflect changes that will not adversely affect compliance with emission standards or operating requirements; and

Request approval to burn hazardous waste for additional operating time after change has been made.

Use of Previous DRE Test Results to Demonstrate Compliance with the MACT DRE Standard

(i) Data Items

Under Section 63.1206(b)(7), previously collected DRE test results may be used to demonstrate compliance with the DRE standard unless the sources is a cement kiln or incinerator that feeds hazardous waste at locations other than the normal flame zone or the source has been modified in a

(ii) Respondent Activities

For sources using historical DRE data in lieu of conducting a new DRE test, provide DRE data that meet quality assurance objectives.

Applicability of Particulate Matter and Opacity Standards during Particulate Matter CEMS Correlation Tests

(i) Data items

Under Section 63.1206(b)(8), any particulate matter and opacity standards at 40 CFR 60, 61, 63, 264, 265, and 266 that are applicable to a HWC do not apply while sources conduct particulate matter continuous emissions monitoring system (CEMS) correlation tests (i.e., correlation with manual stack methods). Sources must develop a particulate matter CEMS correlation test plan that includes the following information:

Number of test conditions and number of runs for each test condition;

Target particulate matter emission level for each test condition;

How the source plans to modify operation to attain the desired particulate matter emission levels; and

Anticipated normal particulate matter emission levels.

Under Section 63.1206(b)(8)(iii)(B), the test plan must be submitted to the Administrator for approval at least 90 calendar days before the correlation test is scheduled to be conducted.

A waiver of the PM and opacity standards during PM CEMS correlation tests may be requested beyond the standard allowed time of 96 hours.

(ii) Respondent activities

Prepare and submit a particulate matter CEMS correlation test plan.

If desired, prepare and submit a waiver request for additional hours of PM CEMS correlation testing beyond the standard 96 hours.

Hazardous Waste Residence Time

(i) Data items

Under 63.1206(b)(11), HWCs must document the hazardous waste residence time in the operating record, and include it in the comprehensive performance test plan, Documentation of Compliance, and Notification of Compliance.

(ii) Respondent activities

Include the hazardous waste residence time in the operating record, test work plan, and Documentation and Notification of Compliance documents.

Startup, Shutdown, and Malfunction Plan

(i) Data items

Under Sections 63.1206(c)(2) and 63.6(e)(3), HWCs must develop and implement a written Startup, Shutdown, and Malfunction Plan that describes procedures for operating and maintaining the source during periods of startup, shutdown, and malfunction. It also contains a program of corrective action for malfunctioning process and air pollution control equipment that is used to comply with the relevant standard. The plan must also identify all routine or otherwise predictable potential CMS malfunctions. The plan must be developed by the source’s compliance date. The SS&M plan must be submitted to the Administrator for review and approval.

When actions taken during a startup, shutdown, or malfunction (including actions taken to correct a malfunction) are consistent with the procedures specified in the affected source’s SS&M Plan, the source must keep records for that event that demonstrate that the procedures specified in the plan were followed. These records may take the form of a “checklist” or other effective form of recordkeeping that confirms compliance with the SS&M Plan for that event.

If an action taken is not consistent with the procedures specified in the plan, the source must report such actions within 2 working days of commencing actions inconsistent with the plan, followed by a letter within 7 working days after the end of the event.

The startup, shutdown, and malfunction provisions exempt sources from the Subpart EEE emission standards and operating requirements during startup, shutdown, and malfunctions. The rule continues to subject sources to RCRA requirements during malfunctions, unless they comply with alternative MACT requirements including expanding the startup, shutdown, and malfunction plan to minimize the frequency and severity of malfunctions, and submit the plan to the delegated CAA authority for review and approval. Sources that burn hazardous waste during startup and shutdown, are required to include waste feed restrictions and operating conditions and limits in the startup, shutdown, and malfunction plan. Sources are also required to include in the startup, shutdown, and malfunction plan a requirement to comply with the automatic hazardous waste feed cutoff system during startup, shutdown, and malfunctions.

The source must keep the written SS&M Plan on record for the life of the affected source or until the affected source is no longer subject to the provisions of 40 CFR Part 63. The plan is to be made available for inspection by the EPA, upon request. In addition, if the plan is revised, the source must keep previous versions of the plan on record for a period of 5 years after each revision to the plan.

Under Section 63.1206(c)(2)(ii)(C) changes to the plan that may increase HAP emissions must be requested in writing within 5 days of making the change.

(ii) Respondent Activities

Develop, submit, and implement, a Startup, Shutdown, and Malfunction Plan, and have it reviewed and approved by the Administrator (or alternatively, contain procedures in the RCRA permit);

Submit additional information if requested by Administrator.

Request approval in writing from EPA within 5 days after making a change to the Startup, Shutdown, and Malfunction Plan that will significantly increase emissions of hazardous air pollutants;

Make the plan available for inspection, if requested by the EPA;

Keep the plan on record for the life of the affected source or until the affected source is no longer subject to the provisions of 40 CFR Part 63; and

Keep previous versions of the plan on record for a period of 5 years after each revision, if the plan is revised.

Automatic Waste Feed Cutoffs (AWFCO)

(i)Data items

Under Section 63.1206(c)(3)(v), if there is an exceedance of an emission standard or operating requirement after any AWFCO, irrespective of whether hazardous waste is in the combustion chamber, HWCs must:

Investigate the cause of the AWFCO;

Take appropriate corrective measures to minimize future AWFCOs; and

Record the findings and corrective measures in the operating record.

Section 63.1206(c)(3)(vi) requires that, for each set of 10 exceedances of an emission standard or operating requirement while hazardous waste remains in the combustion chamber during a 60-day block period, a written report must be submitted within 5 calendar days of the 10th exceedance detailing the results of the investigation and corrective measures taken.

Section 63.1206(c)(3)(vii) requires that the AWFCO system and associated alarms must be tested at least weekly to verify operability, unless it is documented in the operating record that weekly inspections will unduly restrict or upset operations and that less frequent inspection will be adequate. At a minimum, operability testing must be conducted at least monthly. AWFCO operability test procedures and results must be documented and recorded in the operating record.

Section 63.1206(c)(3)(viii) allows for ramping down the waste feedrate of pumpable hazardous waste over a period not to exceed one minute. Sources electing to ramp down the waste feed must document ramp down procedures in the operating and maintenance plan. The procedures must specify that the ramp down begins immediately upon initiation of automatic waste feed cutoff and the procedures must prescribe a bona fide ramping down

(ii) Respondent activities

Investigate the cause of an AWFCO, take appropriate corrective measures to minimize future AWFCOs, and record the findings and corrective measures in the operating record;

Develop and submit a written report documenting excessive exceedances (i.e., a set of 10 exceedances during a 60-day block period) and result of the investigation and corrective measures taken;

Test the AWFCO system and associated alarms weekly and document and record AWFCO operability test procedures and result in the operating record; or,

Alternatively, document in the operating record that weekly inspections will unduly restrict or upset operations and test the AWFCO system monthly and document and record AWFCO operability test procedures and result in the operating record; and

Document in the operating and maintenance plan ramp down procedures, as applicable.

ESV Openings

(i) Data items

Under Section 63.1206(c)(4)(ii), HWCs must develop an emergency safety vent(ESV) plan, comply with the plan, and keep the plan in the operator record. The ESV plan must detail procedures for stopping the waste feed, shutting down the combustor, and maintaining temperature and negative pressure in the combustion chamber. Additionally, Section 63.1206(c)(4)(iii) requires that, after any ESV opening that is not a result of a malfunction, and which occurs when hazardous waste is in the combustion chamber, the HWC must:

Investigate the cause of the ESV opening;

Take appropriate corrective measures to minimize such future ESV openings, and record the findings and corrective measures in the operating record;

Document whether the source remains in compliance with applicable standards; and

Submit a written report to the Administrator if there is non-compliance (within 5 days of the ESV opening).

(ii) Respondent activities

Develop an ESV plan and keep the plan in the operating record;

Investigate the cause of the ESV openings, take appropriate corrective measures to minimize such future ESV openings, and record the findings and corrective measures in the operating record; and

Document whether the ESV caused non-compliance with applicable emissions standards.

Develop and submit a written report within 5 days of the event documenting the ESV opening and result of the investigation and corrective measures taken if non-compliance with applicable emissions standards.

Combustion System Leaks

(i) Data items

Under Section 63.1206(c)(5), combustion system leaks of hazardous air pollutants must be controlled by either:

Keeping the combustion zone sealed to prevent combustion system leaks; or

Maintaining the maximum combustion zone pressure lower than ambient pressure using an instantaneous monitor; or

Upon prior written approval of the administrator, an alternative means of control to provide control of combustion system leaks equivalent to maintenance of combustion zone pressure lower than ambient pressure.

Upon prior written approval of the administrator, other techniques which can be demonstrated to prevent fugitive emissions without use of instantaneous pressure limits.

The method used for control of combustion system leaks must be specified in the operating record, and also included in the comprehensive performance test plan and Notification of Compliance.

(ii) Respondent activities

Prepare and submit a request to use an alternative means of control to provide control of combustion system leaks; and

Specify in the operating record, the comprehensive performance test plan, and in the Notification of compliance the method used for control of combustion system leaks. If applicable the recording frequency of the pressure monitor must be specified.

Operator Training and Certification

(i) Data items

Under Section 63.1206(c)(6), HWCs must establish a training and certification program for all categories of personnel whose activities may reasonably be expected to directly affect emissions of hazardous air pollutants from the source.

Each training program must be of a technical level commensurate with the person’s job duties specified in the training manual. The operator training and certification program must be recorded in the operating record. Control room operators are required to be on duty at source at all times the source is in operation.

The training and certification program for control room operators may be

Developed by the source and be site specific basis, and must follow EPA prescribed training topics outlined in 63.1206(c)(6)(v) or;

A State program, or in the case of incinerator operators only

Program meeting ASME standards QHO-1-1994 or QHO-1a-1996 or. QHO-1-2004

Control room operators must complete an annual review or refresher course as well.

(ii) Respondent activities

Establish a training and certification program for all employees.

Provide training and certification of control room operators under a source-developed program or state program

Provide annual refresher training for control room operators.

Keep records of personnel training and certification.

Operating and Maintenance Plan

(i) Data items

Section 63.1206(c)(7) requires HWC’s to prepare and at all times operate according to a operation and maintenance plan. The operating and maintenance plan must describe in detail procedures for operation, inspection, maintenance, and corrective measures for all components of the combustor, including associated pollution control equipment, that could affect emissions of regulated hazardous air pollutants.

The plan must prescribe how the HWC will operate and maintain the combustor in a manner consistent with good air pollution control practices for minimizing emissions at least to the levels achieved during the comprehensive performance test. The plan must be recorded in the operating record.

(ii) Respondent Activities

Prepare an operation and maintenance plan and record the plan in the operating record.

BLDS and PMDS Requirements

For units with fabric filters, a “bag leak” detectors that meet the specifications in 63.1206 (c ) (8) (ii) or a particulate matter detector system that meets the specification in 63.1206 (c ) (9)must be used to show compliance as part of the operating and maintenance plan. The device must be equipped with an audible alarm. The OMP must outline procedures to follow in the event that the alarm limit is exceeded. EPA must be notified when excessive bag leak detection system exceedances occur. (Specifically if the alarm set point is exceeded more than 5% of the time in any six month block period).

For units with electrostatic precipitator or ionizing wet scrubbers, continuous particulate matter detection systems must be used if alternate site-specific operating limits are not requested and approved under Section 62.1209(m)(1)(iv). The device must be equipped with an audible alarm. The OMP must outline procedures to follow in the event that the alarm limit is exceeded. EPA must be notified when excessive bag leak detection system exceedances occur. (Specifically if the alarm set point is exceeded more than 5% of the time in any six month bloc period). The PM detector may be correlated during the comprehensive performance test. Additional correlation tests are required annually or once every three years depending on the results of the first two tests (see 63.1206 (l)(2))

(ii) Respondent activities

Use bag leak detectors (or PM detectors) for all units with fabric filters.

For units with ESP or IWS, use continuous PM detectors if not complying with alternative operating parameter limits.

Establish alarm levels for BLDS or PMDS

Take corrective action in case the alarm limit is exceeded. Keep records of exceedences (date, time duration of alarm) and corrective action taken.

Notify EPA if excessive bag leak detector exceedences occur.

For units equipped with PM detectors, conduct annual or 3-yearly response audits.

PERFORMANCE TESTING REQUIREMENTS (Section 63.1207)

Comprehensive Performance Test

(i) Data items

Under Section 63.1207(b)(1), HWCs must conduct comprehensive performance testing to demonstrate compliance with MACT Replacement Rule emission standards provided by Sections, 63.1216 through 63.1221; establish limits for the operating parameters provided by Section 63.1209; and demonstrate compliance with the performance specifications for continuous monitoring systems. The initial comprehensive performance test must begin no later than 12 months after the compliance date for Phase I sources, and 6 months for Phase II sources. The comprehensive performance testing is required every 5 years.

Under Section 63.1207(d) (3) the HWC may request additional time (beyond the 60 days after commencement) to complete testing if time is needed for reasons beyond the sources control.

Under Section 63.1207(e)(2), the approved comprehensive performance test plan must be made available to the public (through public notice to persons on the facility public mailing list) no later than 60 days before the initiation of the test.

Under Section 63.1207(h)(2), current operating parameter limits may be requested to be waived during pre-testing for more than the standard 720 hours.

Under Section 63.1207(l)(3)), after a failure of a comprehensive performance test, HWCs may request to burn hazardous waste for more than the standard 720 hours for purposes other than testing or pre-testing.

(ii) Respondent activities

Perform comprehensive performance testing every five years.

If applicable, request a 60 day time extension to complete testing.

If necessary, request additional time to waive current operating parameter limits for pre-testing.

If compliance test fails, petition administrator to burn hazardous waste in the interim period prior to submitting notification of compliance.

Confirmatory Performance Test

(i) Data items

Under Section 63.1207(d)(2), confirmatory performance testing is required mid-way between comprehensive performance testing. Testing is required only for demonstration with the dioxin and furan (PCDD/PCDF) standard.

Units that are not subject to a numerical PCDD/PCDF standard – Liquid fuel boilers with wet or no air pollution control system, HCl Production Furnaces, and solid fuel boilers – must conduct a single PCDD/PCDF performance test (or use previous PCDD/PCDF emissions test measurements if they have sufficient data quality and are representative of current operations).

Under Section 63.1207(g)(2) OPLs established to maintain compliance with the D/F standard, must be held within the range of the average value over the previous 12 months during testing. Also CO or HC CEMS must be between the average and maximum value allowed. The Administrator may approve an alternative operating range

Additionally, for all PCDD/PCDF testing, it may be requested to use Method 23 as an alternative to Method 23A.

(ii) Respondent activities

Conduct confirmatory performance testing at intervals mid-way between the comprehensive performance testing, or

Conduct a one-time PCDD/F test (if source belongs to a category without numerical PCDD/F standard)

Request to operate under wider operating range for a parameter during confirmatory performance testing.

Request to use Method 23A if necessary

Data in Lieu of the Initial Comprehensive Performance Test

(i) Data items

Under Section 63.1207(c)(2), HWCs may request that previous emissions test data serve as documentation of conformance with the emission standards of Subpart EEE, provided that the previous testing:

Meets sufficient quality assurance requirements;

Was conducted after 54 months prior to the compliance date;

Is in conformance with operations during testing requirements for comprehensive performance testing (Section 63.1207(g)(1)); and

Is sufficient to establish the applicable operating parameter limits under Section 63.1209.

(ii) Respondent activities

Prepare and submit a request that previous emissions test data serve as documentation of conformance with emission standards.

Notification of Performance Test and CMS Performance Evaluation, and Approval of Test Plan and CMS Performance Evaluation Plan

(i) Data items

Under Sections 63.1207(e), a notification of intention to conduct a comprehensive and confirmatory performance test and CMS performance evaluation and a site-specific test plan and CMS performance evaluation plan must be submitted at least one year before the performance test and performance evaluation are scheduled to begin. The EPA will notify the source of approval or intent to deny approval of the site-specific test plan and CMS performance evaluation within 9 months after receipt of the original plan.

Under Sections 63.1207(e), and 63.7(b), HWCs must submit a notification to the EPA of their intention to conduct a performance test 60 days before the test is scheduled to begin. In the event the source is unable to conduct the performance test on the date specified in the notification requirement, the source shall notify the EPA within 5 days prior to the scheduled performance date and specify the date when the performance test is rescheduled.

As required by Section 63.7(c), before conducting a required performance test, a site- specific test plan must be submitted to the EPA for approval. The test plan must include:

A test program summary;

The test schedule;

Data quality objectives; and

Both an internal and external quality assurance (QA) program.

Data quality objectives are the pretest expectations of precision, accuracy, and completeness of data.

The internal QA program must include, at a minimum the activities planned to provide an assessment of test data precision (i.e., sampling and analysis of replicate samples). The external QA program must include, at a minimum, application of plans for a test method performance audit (PA) during the performance test. The PA consists of blind audit samples provided by EPA and analyzed during the performance test in order to provide a measure of test data bias. The external QA program may also include systems audits that include the opportunity for on-site evaluation by EPA of instrument calibration, data validation, sample logging, and documentation of quality control data and field maintenance activities.

For confirmatory performance tests, the site-specific test plan must be submitted to EPA at least 60 calendar days before the performance test is scheduled to take place (i.e., simultaneously with the notification of intention to conduct a performance test), or on a mutually agreed upon date. EPA may request additional relevant information after the submittal of a site-specific test plan.

Per 63.1207(e)(2), the site-specific test plan and CMS performance evaluation plan must be made available to the public to review 60 days before the testing starts and a public notice must be issued indicating that the information is available.

(ii) Respondent activities

Prepare and submit a notification of intention to conduct a performance test;

Prepare and submit a rescheduled notification of intent to conduct a performance test, if the test is postponed;

Prepare and submit a site-specific comprehensive performance test plan;

Prepare and submit a CMS performance evaluation test plan.

Prepare and submit additional relevant information requested by the EPA.

Make the approved test plan available to the public, and issue a public notice.

Notification of Compliance

(i) Data items

Sections 63.1207(j)-(l) require that, within 90 days of completion of the comprehensive performance test, HWCs postmark a Notification of Compliance documenting compliance or noncompliance with the emission standards and continuous monitoring system requirements, and identifying operating parameter limits under Section 63.1209 for a comprehensive performance test.

Under Section 63.9(h), the Notification of Compliance must be signed by the responsible official who must certify its accuracy, attesting to whether the source has complied with the relevant standard. The notification must list:

The methods that were used to determine compliance;

The results of the performance test, opacity or visible emission observations, continuous monitoring system (CMS) performance evaluations, and/or other monitoring procedures or methods that were conducted;

The methods that will be used for determining continuing compliance, including a description of monitoring and reporting requirements and test methods;

The type and quantity of hazardous air pollutants emitted by the source, reported in units and averaging times and in accordance with the test methods specified in the relevant standard;

An analysis demonstrating whether the affected source is a major source or an area source;

A description of air pollution control equipment (or method) for each emission point, including each control device (or method) for each hazardous air pollutant and control efficiency (percent) for each control device (or method); and

A statement by the owner or operator of the affected existing, new or reconstructed source as to whether the source has complied watts the relevant standard or other requirements.

As required by Sections 63.7(g) and 63.10(d)(2), and as stated above, results of the performance tests shall be submitted as part of the notification of compliance status.

Under Section 63.1210(d), the Notification of Compliance status requirements of Section 63.9(h) apply, except that:

The notification is a Notification of Compliance, rather the compliance status;

The notification is required for the initial comprehensive performance test and each subsequent comprehensive and confirmatory performance test; and

The notification must be postmarked before the close of business on the 90th day following completion of relevant compliance demonstration activity rather than the 60th day as required by Section 63.9(h)(2)(ii).

The Notification of Compliance requirements of Section 63.1207(j) also apply.

Under Section 63.1207(j) (4), a written request for a time extension may be submitted to the EPA. The request must document that a source may not be able to meet the 90-day deadline for reasons beyond its control.

(ii) Respondent activities

Prepare and submit a Notification of Compliance.

Prepare and submit a written request for a time extension, if necessary.

Waiver of Performance Test or Time Extension for Performance Testing if Test Plan has not been Approved

(i) Data items

Under Section 63.7(h), Section 63.1207(e)(3), and Section 62.1207(i), performance tests may be requested to be waived (or given a time extension of up to one year to conduct the performance test) with a written application to the EPA if:

The source is meeting the relevant standards on a continuous basis;

The test plan has been submitted to EPA but has not yet been approved.

The application for a waiver or time extension must be submitted at least 60 days before the required performance test data, or 60 days before the scheduled date of the performance test if the site-specific test plan has been submitted but not yet approved.

The application for a waiver of a performance test must include information justifying the source’s request for a waiver, such as the technical or economic infeasibility, or the impracticality, of the affected source performing the required test. It must also include documentation to enable the EPA to determine that the source is meeting the relevant standards on a continuous basis as required by Section 63.7(h)(2). Extension requests for the initial comprehensive performance test must include a Documentation of Compliance to assist EPA in making this determination.

Also, the source must notify the public of the petition to waive the performance test.

Additionally, under Section 63.1207(m), HWCs are not required to conduct performance tests to document compliance with the mercury, semivolatile metal, low volatile metal or total chlorine gas emission standard if the twelve-hour rolling average maximum theoretical emission concentration (MTEC) does not exceed the emission standard. To document compliance with this provision, HWCs must:

Monitor and record the feedrate of mercury, semivolatile metals, low volatile metals, and total chlorine from all feedstreams according to Section 63.1209(c);

Monitor with a CMS and record in the operating record the gas flowrate (either directly or by monitoring a surrogate parameter that is correlated to gas flowrate);

Continuously calculate and record in the operating record the MTEC;

Or alternatively,

Identify in the Notification of Compliance a minimum gas flowrate limit and a maximum federate limit of mercury, semivolatile metals, low volatile metals, and/or total chlorine from all feedstreams that ensues the MTEC is below the applicable emission standard; and

Interlock the MTEC calculated or the minimum gas flowrate limit and maximum federate limit to the AWFCO system to stop hazardous waste burning when the MTEC exceeds the emission standard or when the gas flowrate or mercury, semivolatile metals, low volatile metals, and/or total chlorine federate exceeds the limit as identified in the Notification of Compliance.

It must be stated in the site-specific test plan submitted for review and approval the intention to comply with the provisions of 63.1207(m).

(ii) Respondent activities

Prepare and submit an application for a waiver or time extension of performance test.

Notify public of waiver or time extension request.

MONITORING REQUIREMENTS (Section 63.1209)

Continuous Emissions Monitoring Systems (CEMS) and Continuous Opacity Monitoring Systems (COMS)

(i) Data items

Under Section 63.1209(a), HWCs must use a CEMS to demonstrate and monitor compliance with the carbon monoxide and/or hydrocarbon standards. HWCs must also use an oxygen CEMS to continuously correct the carbon monoxide and hydrocarbon levels to 7 percent oxygen.

Additionally, cement kilns not equipped with bag leak detector, must use a COMS to demonstrate and monitor compliance with opacity standards for existing and new kilns. Certain cement kilns may conduct daily visual stack testing (per Method 9) in lieu of COMS.

(ii) Respondent activities

Install, calibrate, maintain, and continuously operate CEMS for carbon monoxide, hydrocarbons, and oxygen; and

For existing and new cement kilns, install, calibrate, maintain, and continuously operate COMS for opacity, or

Conduct daily visual stack testing

Use of CEMS in Lieu of Operating Parameter Limits or Alternative Methods in-Lieu of CEMS

(i) Data items

Under Sections 63.1209(a)(5) and 63.8(f), HWCs may request the use of CEMS in lieu of operating parameter limits, or alternative methods in lieu of CEMS.

(ii) Respondent activities

Request the use of CEMS in lieu of operating parameter limits, or alternative methods in lieu of CEMS.

Other Continuous Monitoring Systems

(i) Data items

Under Section 63.1209(b) other continuous monitoring systems (such as thermocouples, pyrometers, pressure transducers and flow meters) must be used to monitor various combustion and air pollution control device operating parameters. Sources must follow manufacturers written specifications for installation, operation and calibration of CMS.

CMS evaluation plan and test plan must also be developed as discussed below in more detail.

(ii) Respondent activities

Install and operate all CMS as required for compliance with required operating parameter limits.

Feedstream Analysis Plan

(i) Data items

Section 63.1209(c)(2) requires HWC to develop and implement a feedstream analysis plan and record it in the operating record. If requested the plan must be submitted to the administrator for review and approval. The plan must specify at a minimum:

The parameters for which each feedstream will be analyzed to ensure compliance with the operating parameter limits of 40 CFR Part 63;

Whether the source will obtain the analysis by performing sampling and analysis or by other methods, such as using analytical information obtained from others.

How the analysis will be used to document compliance with all applicable feedrate limits (e.g., if hazardous wastes are blended and obtain analyses of the wastes prior to blending but not of the blended, unfired, waste, the plan must describe how the pertinent parameters if the blended waste will be determined);

The test methods which will be used to obtain the analyses;

The sampling method which will be used to obtain a representative sample of each feedstream to be analyzed using the sampling methods described in Appendix 1X of Part 266 or an equivalent method; and

The frequency with which the initial analysis of the feedstream will be reviewed or repeated to ensure that the analysis is accurate and up to date.

Additionally, under Section 63.1209(c)(4), to comply with the applicable federate limits, feedrates must be monitored and recorded as follows:

Determine and record the value of the parameter for each feedstream by sampling and analysis or other method;

Determine and record the mass or volume flowrate of each feedstream by CMS.

If the flowrate of a feedstream in determined by volume, the density of the feedstream must be determined and recorded by sampling and analysis (unless the constituent concentration is reported in units of weight per unit volume (e.g., mg/L)); and

Calculate and record the mass federate of the parameter per unit time.

(ii) Respondent activities

Develop and implement a feedstream analysis plan and record the plan in the operating record;

Submit the plan for review and approval, if requested by the EPA; and

Monitor and record feedrates.

CMS Quality Control Program

(i) Data items

Under Sections 63.1209(d) and 63.8(d), HWCs must develop and implement a CMS quality control program. Each quality control program must include, at a minimum, a written protocol that describes procedures for each of the following operations:

Initial and any subsequent calibration of the CMS;

Determination and adjustment of the calibration drift of the CMS;

Preventive maintenance of the CMS, including spare parts inventory;

Data recording, calculations, and reporting;

Accuracy audit procedures, including sampling and analysis methods; and

Program of corrective action for a malfunctioning CMS.

Sources must keep these written procedures on record for the life of the affected source or until the affected source is no longer subject to the provisions of 40 CFR Part 63, and are to be made available for inspection by the EPA, if requested. Where relevant, these written procedures may be incorporated as part of the affected source’s startup, shutdown, and malfunction plan to avoid duplication of planning and recordkeeping efforts.

(ii) Respondent activities

Develop and implement a CMS quality control program;

Keep the CMS quality control program on record for the life of the affected source or until the affected source is no longer subject to the provisions of 40 CFR Part 63; and

Submit the CMS quality control program for inspection, if requested by the EPA.

Notification of CMS Performance Evaluation

(i) Data items

As required by Sections 63.1209(d) and 63.8(e)(2), HWCs must notify the EPA in writing of the date of the performance evaluation simultaneously with the notification of the performance test date required under Section 63.7(b) or at least 60 days prior to the date the performance evaluation is scheduled to begin if no performance test is required. It is noted that Section 63.8(e)(2) is superseded by Section 63.1207(e) requiring sources to submit the site-specific test plan and the CMS performance evaluation plan for approval at least one year prior to the planned test date.

(ii) Respondent activities

Prepare and submit a notification of CMS performance evaluation.

Additional Notification Requirements for CMS

(i) Data items

Under Section 63.1210(a)(1) and Sections 63.9(g)(2) and (3), HWCs must furnish the EPA with the following written notifications:

A notification that COMS data results will be used to determine compliance with the applicable opacity emission standard during a performance test, if compliance with an opacity emission standard is required for the source by the relevant standard. The notification shut be submitted at least 60 calendar day: before the performance test is scheduled to begin; and

A notification that the criterion necessary to continue use of an alternative to relative accuracy testing has been exceeded. The notification shall be delivered or postmarked not later the 10 days after the occurrence of such exceedance, and it shall include a description of the nature and cause of the increased emissions.

(ii) Respondent activities

Prepare and submit additional notification requirements for sources with CMS.

Submission of Site-Specific CMS Performance Evaluation Test Plan

(i) Data items

As required by Section 63.1209(d) and 63.8(e)(3), before conducting a required CMS performance evaluation, HWCs must develop and submit a site-specific performance evaluation test plan to the EPA for approval upon request. The performance evaluation test plan shall include:

The evaluation program objectives;

An evaluation program summary;

The performance evaluation schedule;

Data quality objectives; and

Both an internal and external QA program.

Data quality objectives are the pre-evaluation expectations of precision, accuracy, and completeness of day.

The internal QA program shall include, at a minimum, the activities planned by routine operators and analysts to provide an assessment of CMS performance. The external QA program shall include, at a minimal system audits that include the opportunity for on-site evaluation by the EPA of instrument calibration, data validation, sample logging, and documentation of quality control data and held maintenance activities.

The source shall submit the site-specific performance evaluation test plan to the EPA (if requested) at least 60 days before the performance test or performance evaluation is scheduled to begin, or on a mutually agreed upon date. The EPA may request additional relevant information after the submittal of a site-specific performance evaluation test plan.

It is noted that Section 63.8(e)(3)(iii) is superseded by Section 63.1207(e) requiring sources to submit the site-specific test plan and the CMS performance evaluation plan for approval at least one year prior to the planned test date.

(ii) Respondent activities

Develop and submit a CMS site-specific performance evaluation test plan; and

Submit additional relevant information, if requested by the EPA.

Conduct of CMS Performance Evaluation and Performance Evaluation Dates

(i) Data items

Under Section 63.1209(d) and 63.8(e))(4), the HWCs must conduct a performance evaluation of a required CMS during any performance test required under Section 63.7 in accordance with the applicable performance specification as specified in the relevant standard. Additionally, performance evaluations of components of the CMS must be conducted under the frequency and procedures (for example, submittal of performance evaluation test plan for review and approval) applicable to performance tests as provided by Section 63.1207.

(ii) Respondent activities

Conduct a CMS performance evaluation.

Reporting Results of CMS Performance Evaluations

(i) Data items

Under Section 63.8(e)(5), the owner or operator of an affected source required to install a CMS by the relevant standard shall furnish the EPA a copy of a written report of the results of the CMS performance evaluation, simultaneously with the results of the performance test.. Additionally, sources using a COMS to determine opacity compliance during any performance test shall furnish to EPA two or, upon request, three copies of a written report of the results of the COMS performance evaluation. The copies shall be furnished at least 15 calendar days before the performance test.

(ii) Respondent activities

Prepare and submit a written report of the results of the CMS performance evaluation; and

Prepare and submit written reports of the result of the COMS performance evaluation, as applicable.

Alternative Compliance Monitoring Requirements for Standards other than those Monitored with a CEMS

(i) Data items

Under Section 63.1209(g)(1), HWCs may submit an application to the EPA for approval of alterative monitoring requirements to document compliance with the emission standards of Subpart EEE other than CO or HC which are monitored with a CEMS. An application to waive an operating parameter limit may be submitted based on documentation that neither that operating parameter limit nor an alternative operating parameter limit is needed to ensure compliance with the emission standards of Subpart EEE. The application must be submitted to the EPA not later than with the comprehensive test plan. The application must include:

Data or information justifying the request for an alternative monitoring requirement (or for a waiver of an operating parameter limit), such as the technical or economic infeasibility or the impracticality of using the required approach;

A description of the proposed alternative monitoring requirement, including the operating parameter to be monitored, the monitoring approach/technique (e.g., type of detector, monitoring location), the averaging period for the limit, and how the limit is to be calculated; and

Data or information documenting that the alternative monitoring requirement would provide equivalent or better assurance of compliance with the relevant emission standard, or that it is the monitoring requirement that best assures compliance with the standard and that is technically and economically practicable.

The administrator will notify approval or intention to deny approval of the request within 90 calendar days after receipt of the original request and within 60 calendar days after the receipt of any supplementary information that is submitted. The EPA may determine on a case-by-case basis at any time that additional or alternative operating parameters may need to be limited, or that alternative approaches to establish limits on operating parameters may be necessary to document compliance with the emission standards of Subpart EEE.

(ii) Respondent Activities

Prepare and submit an application for use of an alternative monitoring method for operating parameter requirements; and/or;

Prepare and submit an application to waive operating parameter limits.

Destruction and Removal Efficiency

(i) Data items

Under Section 63.1209(j), HWCs must remain in compliance with the destruction and removal efficiency (DRE) standard by establishing operating limits during the comprehensive performance test (or during a previous DRE test) and complying with those limits at all times that hazardous waste remains in the combustion chamber. OPLs must be established and complied with for:

Minimum combustion chamber temperature;

Maximum flue gas flowrate or production rate;

Maximum hazardous waste federate; and

Operation of waste firing system.

(ii) Respondent activities

Comply with the following operating limits: minimum combustion chamber temperature; maximal gas flowrate or production rate; maximum hazardous waste feedrate, and operation of waste firing system.

PCDD/PCDF

(i) Data items

Under Section 63.1209(k), HWCs must comply with the dioxin and furan emission standard by establishing and complying with the following operating parameter limits based limits on operations during the comprehensive performance test:

Gas temperature at the inlet to a dry particulate matter control device (LWAKs must instead measure gas temperature at the exit of the last combustion chamber);

Minimum combustion chamber temperature (applies to all sources except cement kilns),

Maximum flue gas flowrate or production rate

Maximum hazardous waste feedrate;

Parameter limits for the following air pollution control devices:

Activated carbon injection systems, with limits including carbon feedrate and operating temperature, as well as parameter limits for PM capture device;

Carbon bed systems, where operating parameters to monitor and control bed age must be specified on a site specific basis in the comprehensive performance test plan;

Catalytic oxidizers, with limits on operating temperature; and

Inhibitor federates.

Under Section 63.1209(k)(6)(iii)(B), HWCs equipped with activated carbon injection systems may substitute at any time a different brand or type of carbon provided that the replacement has equivalent or improved properties compared to the carbon used in the performance test and conforms to the key solvent parameters. Documentation that the substitute carbon will provide the same level of control as the original carbon must be included in the operating record.

Under Section 63.1209(k)(7)(ii)(B), HWCs equipped with carbon bed systems day substitute at any time a different bind or type of carbon provided that the replacement his equivalent or improved properties compared to the carbon used in the performance test.

Documentation that the substitute carbon will provide the same level of control as the original carbon must be included in the operating record.

For HWCs feeding dioxin/furans inhibitors into the combustion system, under Section 63.1209(k)(9)(ii)(B), a different brand or type of inhibitor may be substituted at any time provided that the replacement has equivalent or improved properties compared to the inhibitor used in the performance test and conforms to the key parameter that affect the effectiveness of the inhibitor. Documentation that the substitute inhibitor will provide the some level of control as the original inhibitor must be included in the operating record.

(ii) Respondent activities

Comply with the following operating parameter limits:

Gas temperature at the inlet to a dry particulate matter control device;

Minimum combustion chamber temperature;

Maximum flue gas flowrate or production rate;

Maximum hazardous waste federate; particulate matter operating limit;

Operating parameter limits for activated carbon injection or carbon bed systems, catalytic oxidizers, and inhibitors; and

If carbon is used, document in the operating record that replacement carbon will provide the same level of control as the original carbon used during the performance test.

If inhibitors are used, document in the operating record that replacement inhibitor will provide the some level of control as the original inhibitor used during the performance test.

Mercury

(i) Data items

Under Section 63.1209(l) HWCs must comply with the mercury emission standard by establishing and complying with the following operating parameter limits. These limits must be based on operations during the comprehensive performance test (or manufacturer specifications):

Feedrate of total mercury; and

Parameter limits for the following air pollution control devices:

- Wet scrubbers;

- Activated carbon injection systems; and

- Activated carbon bed systems.

A 12 hour rolling average limit (or an annual rolling average limit in the case of liquid boilers) for the total feedrate of mercury in all feedstreams must be established as the average of the hourly rolling averages for each run.

However, under Sections 63.1220(a)(2)(iii), 63.1221 (a)(2)(ii) cement kilns and LWAKs complying with the alternate mercury standard would establish a 12 hour rolling average limit for mercury from hazardous waste feedstreams.

Under Section 63.1209(l)(1)(v) sources may request as part of the performance test plan to use the Hg feedrates and associated emission rates during the CPT to extrapolate to higher feedrates.

(ii) Respondent activities

Comply with the following operating parameter limits: feedrate of total mercury; and parameter limits for wet scrubbers, and activated carbon injection or carbon bed systems; or

Install, calibrate, maintain and continuously operate CEMS for compliance monitoring for mercury.

Request to extrapolate mercury feedrate limits.

Particulate Matter

(i) Data items

Under Section 63.1209(m), HWCs must comply with the particulate matter emission standard by establishing and complying with the following operating parameter limits based on operations during the comprehensive performance test:

APCD operating limits for:

- Wet scrubbers- scrubber liquid/gas ratio, scrubber liquor solid content and for high energy wet scrubbers only – min pressure drop

- Baghouses, including pressure drop and gas flowrate.

- Electrostatic precipitators, including power input and gas flowrate.

- Other particulate matter control devices.

Maximal flue gas flowrate or production rate, and

Maximum ash feedrate.

Alternately, install, calibrate, maintain and continuously operate CEMS for compliance monitoring for PM.

(ii) Respondent activities

Comply with the following operating parameter limits:

APCD operating limits for wet scrubbers, fabric filters, or electrostatic precipitators

Maximum flue gas flowrate or production rate; and Maximum ash feedrate;

Semivolatile Metals and Low Volatile Metals

(i) Data items

Under Section 63.1209(n), HWCs must comply with the semivolatile metal (cadmium and lead) and low volatile metal (arsenic, beryllium, and chromium) emission standards by establishing and complying with the following operating parameter limits base on operations during the comprehensive performance test:

Maximize inlet temperature to dry particulate matter air pollution control device;

Maximum feedrate of semivolatile and low volatile metals; APCD operating parameter limits specified for particulate matter;

Maximum total chlorine and chloride federate; and

Maximum flue gas flowrate or production rate.

A 12-hour rolling average limit for the federates of combined semivolatile metals and combined low volatile metals must be established, in all feedstreams as the average of the average hourly rolling averages for each run, as well as a 12-hour rolling average limit for combined semivolatile metals in all pumpable feedstream as the average of the average houry rolling averages for each run. Dual feedrate limits for both pumpable and total feedstreams are not used if the total feedrate limit is based solely on the feedrate of pumpable feedstreams.

Under Section 63.1209(n)(2)(ii) the use semivolatile metal and low volatile metal feedrates and associated emission rates during the comprehensive performance test to extrapolate to higher allowable federate limits and emission rates may be requested as part of the performance test plan.

(ii) Respondent activities

Comply with the following operating parameter limits:

Maximum inlet temperature to dry particulate matter air pollution control device;

Maximum feedrate of semivolatile and low volatile metals;

APCD operating parameter limits specified for particulate matter;

Maximum total chlorine and chloride feedrate

Maximum flue gas flowrate or production rate; and

Prepare and submit request to extrapolate semivolatile metal and low volatile metal feedrate limits; or

Request to extrapolate semivolatile and low volatile metal feedrate limits.

Total Chlorine (Hydrogen Chloride and Chlorine Gas)

(i) Data items

Under Section 63.1209(o), HWCs must comply with the total chlorine emission standard by establishing and complying with the following operating parameter limits based on operations during the comprehensive performance test:

Feedrate of total chlorine and chloride;

Maximum flue gas flowrate or production rate;

Parameter limits for the following air pollution control devices: wet scrubbers and dry scrubbers.

For HWCs equipped with dry scrubbers, under Section 63.1209(o)(4)(iii)(B), a different brand or type of sorbent may be substituted at any time provided that the replacement has equivalent or improved properties compared to the serpent used in the performance test and conforms to the key parameters. Documentation that the substitute sorbent will provide the some level of control as the original sorbent must be included in the operating record.

(ii) Respondent activities

Comply with the following operating parameter limits:

Comply with the following operating parameter limits feedrate of total chlorine and chloride; maximum flue gas flowrate or production rate; and operating parameter limits for wet and dry scrubbers; and

Document in the operating record that replacement sorbent will provide the same level of control as the original sorbent used during the performance test;

Combustion Chamber Pressure

(i) Data items

Under 63.1209 (p), instantaneous monitoring of combustion zone pressure (ensuring that the combustion zone pressure is lower than ambient pressure) may be used to comply with provisions for controlling combustion system leaks.

(ii) Respondent activities

Monitor and record combustion zone pressure.

Operating under Different Modes of Operation

(i) Data items

Given that HWCs must establish limits for applicable operating parameters based on operations during the comprehensive performance test, under Section 63.1207(g)(1)(i), a HWC may conduct testing under two or more operating modes to provide operating flexibility.

Under Section 63.1209(q), when the HWC changes a mode of operation and begins complying with the operating parameter limits for an alternative mode of operation, it must be recorded in the operating record.

Document the mode of operation in the operating record, if a source has tested under two or more operating modes.

NOTIFICATION REQUIREMENTS (Section 63.1210)

HWCs must submit various notifications listed under Section 63.1210(a)(1).. HWCs may also choose to submit a number of notifications listed under Section 63.1210(a)(2) for requests, petitions, or applications in order to comply with reduced or alternative requirements. Note that several of these notifications have been addressed in other sections of this ICR. This section provides descriptions of notification requirements not discussed in preceding or later sections of this document.

Initial Notifications

(i) Data items

A Notification of Intent to Comply (NIC) must be prepared by all sources as outlined in 63.1210 (b). The NIC must discuss various milestone dates of key activities that are planned to bring the source into compliance and a description of the source and how it intends to comply with the HWC MACT Rule.

The initial notification requirements of Section 63.9(b) apply when sources become subject to the relevant standard. Sources with an initial startup date before the effective date of the relevant standard must notify the EPA in writing that the source is subject to the relevant standard. The notification must be submitted not later than 120 calendar days after the effective date of the relevant standard (or within 120 calendar days of the source becomes subject to the relevant standard), and shall provide the following information:

The name and address of the owner or operator;

The address of the affected source;

An identification of the relevant standard, or other requirement, that is the basis of the notification and the source's compliance date;

A brief description of the nature, size, design, and method of operation of the source, including its operating design capacity and an identification of each point of emission for each hazardous air pollutant, or if a definitive identification is not yet possible, a preliminary identification of each point of emission for each hazardous air pollutant; and

A statement of whether the affected source is a major source or an area source.

A new or reconstructed affected source, or a source that has been reconstructed such that it is an affected source, with an initial startup after the effective date of the relevant standard and for which reapplication for approval of construction or reconstruction is not required, must notify the EPA in writing that the source is subject to the relevant standard no later the 120 days after initial startup. The notification must provide all the information listed above.

After the effective date of the relevant standard, sources who intend to construct a new affected source, or reconstruct a source such that it becomes an affected source, must notify the EPA in writing of the intended construction or reconstruction. The notification must be submitted as soon as practicable before the construction or reconstruction commences after the effective date of the relevant standard or as soon as practicable before startup but no later than 60 days of the relevant standard if the construction or reconstruction had commenced and initial startup has not occurred before the standard’s effective date. The notification must include all the information required for an application for approval of construction or reconstruction, as described below.

A public meeting must be held to discuss the NIC, conducted at least 10 months before the initial rule compliance date. A draft NIC must be made available to the public 30 days before the meeting. The final NIC must be submitted to EPA within 1 year of the effective rule date. The final NIC must include a summary of the public meeting.

A progress report must be prepared not later than 2 years after the effective rule date. The progress report must discuss information documenting the completion of activities contained in the NIC; and a updated schedule of future activities to comply with the MACT standards.

ii) Respondent activities

Prepare and submit initial notice

Prepare draft NIC;

Notify public;

Conduct public meeting;

Prepare and submit the final NIC;

Prepare and submit progress report

Change in Information Already Provided

(i) Data items

As required by Section 63.9(j), any change is the information already provided under Section 63.9 must be provided to the EPA in writing within 15 calendar days after the change.

(ii) Respondent activities

Submit change(s) in the information already provided.

Application for Approval of Construction or Reconstruction

(i) Data items